Prepress & Screen Making

Published

22 years agoon

Automatic stencil-developing technology has become increasingly common in screen-printing operations, and many businesses that haven’t already added such systems are beginning to give developing equipment serious consideration. An automatic developing system works much like an automatic screen washer. These units, which may be standalone systems or part of conveyorized screenmaking lines, house spray nozzles that deliver a uniform low-pressure wash to remove unexposed emulsion without damaging the stencil image.

Automatic stencil-developing technology has become increasingly common in screen-printing operations, and many businesses that haven’t already added such systems are beginning to give developing equipment serious consideration. An automatic developing system works much like an automatic screen washer. These units, which may be standalone systems or part of conveyorized screenmaking lines, house spray nozzles that deliver a uniform low-pressure wash to remove unexposed emulsion without damaging the stencil image. Automatic stencil-developing systems are available from most screen-printing equipment manufacturers and suppliers.

The traditional, hand-based stencil-developing method may rely on several employees with varying levels of skill who use a garden hose or pressure washer to resolve image areas in the exposed stencil. While hand-developed stencils may be acceptable, they are more likely than those developed automatically to contain inconsistencies that make them flawed or even unusable.

Spray characteristics and stencil quality

In a process where reducing the variables is crucial to success, having screens developed under a controlled pattern of sprayed water is vital, as is using the correct pressure and angle for spraying. These factors are harder to control in manual developing than on automated systems, which is why hand-developed screens are more likely to have inconsistencies and inferior stencil quality. In some cases, however, manual developing may be acceptable, such as when the washed-out image is bold and doesn’t require high edge definition.

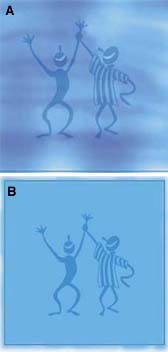

With fine details and halftone dots, however, the stencil edge quality is much more critical and those responsible for manually developing stencils must be diligent in their work. Hand developing high-resolution stencils takes time and skill, and even the most expert screenmaking technician will struggle to achieve consistent washout results over the entire image area of a screen <B>(Figure 1A)</B>.

With an automated system, however, it’s possible to control pressure, angle of flow, speed of traverse, and coverage, while simultaneously washing out both sides of the screen <B>(Figure 1B)</B>. Detail that was almost impossible to develop manually will wash out much more cleanly with an automated developing system. Not until you use an automatic developer for the first time do you realize the quality and consistency that such a system makes possible. And it is not just image quality where these advantages are apparent.

Water recycling

A typical automatic developing machine reuses 90% of its processing water. This recycled water, which is filtered to remove the uncured emulsion particles, is used for the majority of the developing cycle. Only at the end of the cycle is fresh water used for final rinsing (this water is also added to the recycling volume).

Such water conservation is very significant when you consider the amount (and cost) of incoming fresh water and outgoing wastewater used in traditional hand-developing operations. On average, the water consumption for hand developing runs in excess of 4 gal per average-size screen, while an automated system with water recycling may consume less than 1 gal of fresh water for the same size screen.

Labor savings

The reduction in labor that results from automating the developing process can be substantial, averaging about 20 man-hours/week in a typical operation. While the machine is busy processing, the operator can be used in other areas. Additionally, the machine works through lunch and coffee breaks and requires no special skills to operate. It also doesn’t get fed up or bored, and I have never known an automatic developer to have a hangover on Monday morning.

Consistency

One of the biggest advantages of automatic developing is consistency. When screens are processed manually, some reworking may be necessary because a bored or tired employee didn’t develop the screen properly the first time or because the results you get from one employee don’t match those from another. This does not take into account the cost of waste materials on the press and rejected prints. You could lose a whole job and even a customer over problems associated with reworks. Risks such as these are not worth taking in an increasingly competitive marketplace.

The complete process control and consistency you get from automatic developing helps eliminate the need for reworking screens and the high costs associated with these reworks. In addition, since screens in an automatic system are washed from both sides with exactly the same pressure, you are guaranteed an even washout every time. This balanced pressure also prolongs the screen tension and helps the mesh last longer.

A key to continued quality from automated developing equipment is maintaining the condition of the spray jets. If jets become blocked, the uncured emulsion on screens being processed will not be completely removed. This will result in an improperly developed stencil and poor print quality on press.

Health and safety

When developing is automated, the possibility of repetitive-motion injury from manual washout procedures is eliminated. Also, automatic equipment frequently encloses the whole developing process so that sound levels are significantly reduced and the area is much easier to keep dry.

Lower humidity

Maintaining steady levels of humidity in a screenmaking department is an important element of process control. The enclosed format of an automatic system reduces the presence of water mist in the atmosphere and, thus, humidity levels. We have spoken in previous articles about the need to keep the moisture content of the dried emulsion below 6%, and ideally at 4%. Moisture levels higher than these in an unexposed emulsion will alter the required exposure time and often lead to underexposed stencils. Changes in humidity also will affect the size of the photopositive and, ultimately, the stencil image.

Moving toward automation

A range of automated stencil-developing systems are available. If you are considering upgrading your screenmaking process, investing in automatic developing equipment is a wise way to improve your product quality and productivity. Automatic screen cleaning, stencil-reclaiming, and degreasing equipment would be other additions to consider as well. And for a fully automated screenmaking department, you may even want to consider computer-to-screen and direct projection imaging systems that incorporate automated screen-handling.

The stencil is the basis of the screen-printing process, and the consistency in stencil quality you get from automatic-developing equipment gives you a firm foundation from which to print. However, if you don’t control mesh tension, frame integrity, and other aspects of the screen, don’t bother investing in automatic equipment.

The payback time on automation in the stencil department is dependent on your production volume and quality requirements. However, there are very few shops with screenmaking demands of more than a dozen stencils per day that couldn’t justify the addition of an automatic developing system. And if you make the investment in such equipment, don’t be surprised if it delivers much greater rewards and savings than you expected.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?