Articles

Published

21 years agoon

In the pad-printing industry, purchasing decisions are often based on assumptions that are simply nuts–literally. The president of a company will see a pad-printing machine printing nuts at an exhibition and be suckered by the salesperson into believing that this process will print on anything. When asked how fast the machine will print, the salesperson replies, “1500 per hour, hand fed.” Dream on!

During more than 25 years of involvement with pad printing, we have not come across a truly bad machine. We’ve also never encountered an ideal one. Many different machine styles are available today, each with strengths and weaknesses. Understanding the differences between the machine styles and how they may affect the application at hand will help you determine which machine is best for your needs.

Basic needs

Some machine requirements are consistent for all pad-printing applications. The machine has to transfer ink from an image carrier (a plate or cliche) via a flexible (silicone) pad onto a substrate. It must be able to carry out this pick-and-place function as accurately as possible, ideally within ±0.0001 in. (±0.025 mm). It should operate smoothly, free of unwanted vibration at production speeds. The machine should be designed in such a way that the operator can simply regulate the ink conditions and maintain the drying rate of the solvents in the ink. The ability to maintain the ink condition, and therefore the printing conditions, is of prime importance and is a feature that many machines lack.

Manually operated machines

The first pad-printing machines were manually operated (Figure 1). Very high-quality watch and instrument dials have been printed over the years using hand-powered machines. Today, the only reason for buying them is the low initial cost. Except in cases where pad printing will be carried out on a small scale, they are not really entry-level machines. Print rates are very low and maintaining quality over a continuous run is extremely difficult. A well-engineered unit can be useful for testing plates, pads, inks, and designs as an alternative to taking a production machine off line.

Open ink-trough machines

In these machines, which were the first semiautomatic models available (dating to the late 1960s), the inking mechanism is mounted above the plate. Many machines of this type (Figure 2) are out in the field. Over the years, this style has been further developed, and a host of machines has been produced using electropneumatic and even servomotor drives. Also, PLCs (programmable logic controllers) are common, providing a wide range of sequencing options.

No matter how sophisticated these machines are, controlling ink conditions is problematic due to the large surface area exposed to the atmosphere. This can be ameliorated in different ways. Some manufacturers help reduce evaporation by “shrouding” the inking mechanism and inkwell. Other manufacturers use ink pumps and solvent-addition systems to compensate for the evaporation. Still, it is surprising to us that this machine design is so widely used, given the ink/solvent balance.

Changeover of ink and plate can be carried out relatively quickly by removing the entire ink tray, including the plate, and replacing it with another that has already been prepared. You must consider the cost of spare ink trays, which can be very expensive. The ink tray can be designed to catch ink that spills over the front of the plate, thus keeping the machine cleaner.

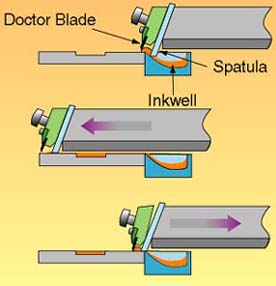

Machines with partially covered ink troughs

We have to admit a prejudice: This is our favorite machine style when well engineered. Ink is contained in a trough located behind the plate, as shown in (Figure 3). The ink is pulled forward out of the trough by a spatula that is mounted on a horizontal carriage together with

the doctor-blade assembly. (Think of the squeegee/floodbar assembly on a screen-printing press). While ink is being flooded across the plate, the horizontal carriage covers it and reduces solvent evaporation. When retracted, the mechanism covers the ink trough. This does not seal in the ink as with a closed-cup machine, but it does inhibit the evaporation of solvents. The ink/solvent mix will remain stable longer than in a completely open trough.

These machines must be robustly engineered. Considerable movement occurs in the bearings at the rear of the carriage during the time that the doctor blade contacts the plate. Inadequate bearings will quickly degrade and the carriage will become unstable, which results in poor doctoring and uneven plate wear. Even ideal systems must be kept clean and not overfilled with ink. Do not allow the spatula, which is normally free floating on these machines, to become fouled with ink or else it may stick up or down. (Carol spent a year growing red ink out of her blonde hair after an inking mechanism stuck and then released suddenly because the operator had overfilled it.)

Machines with sealed ink cups

These machines are designed to contain the ink in a cup that is turned upside down and pressed firmly against the plate, sealing in the ink (Figure 4). The cup holds the ink and also acts as the doctor blade. The advantage of this system is that solvent evaporation is reduced to a minimum. This allows much closer control of ink conditions, resulting in the opportunity for reduced downtime and partially unmanned operation.

Closed-cup systems were considered by some to be the panacea of all pad-printing ills. “But,” you say, “the salesman told me it will run 24 hours a day, seven days a week, 52 weeks a year.” Did he say what the print quality would be, how often you would have to add ink, how much the plate would wear, or how long the cup would last?

Did he mention that you couldn’t ignore the fact that the ink does degrade in the cup over time? When using two-component inks, you must change the ink before the end of its pot life. This can be 4 hr in some cases. Were you informed that the plate should be twice the size of a plate used in an open ink-trough machine for a given image, or that it is better to keep the plates and cups as matched pairs?

This raises another question you should ask when shopping for such a system: How much does a replacement cup cost? The answer may be a surprise: $500 is not at all unusual. Fortunately, if the damage to the cup is very slight, it can be repaired by carefully honing the contact surface on a fine carborundum stone. Some cups can be remachined at a quarter of the replacement costs. This all means that the cups must be handled very carefully.

Types of ink cups Ink cups come in different constructions. The simplest is machined from solid metal, normally hardened steel. The second type has a ribbon-steel contact surface that can be replaced when worn. The third is a metal cup with a ceramic contact surface bonded onto the metal. This type provides a very good life, but is more expensive than a conventional cup. Ceramic contact cups are a good choice when working with photopolymer plates. Metal cups tend to tear at the surface of the plate.

To achieve maximum usage with any of these cups, apply minimum pressure and be certain that the cup is mounted on a stable bearing. If the plate/cup mounting is not stable, it will cause the cup to rock, resulting in uneven wear and leaving a film of ink on the plate that will have a tendency to transfer.

Some systems use a magnet to hold the cup onto the plate, which appears to work very well. Plate and cup wear with a magnet can be less than in a vertical-loading arrangement, thus allowing satisfactory change from one plate to another without having to change the cup as well. A note of caution when using cups with magnets–be aware of ink selection. Some inks contain carbon, and the magnet causes the pigment to separate in the cup.

There is no doubt that sealed-cup systems are being further refined. They were available only in limited print sizes originally, but the use of larger cups is changing this. Some manufactures have tried to increase the usable image size by making the cups oval in shape. The effectiveness of this is questionable, because the narrowness of the cup from front to back compromises its stability. Probably the more effective method of increasing image size is to use a round cup on a long plate and move the cup side to side. This would allow the use of a 100-mm-diameter cup on a 120 x 450-mm plate.

Another interesting variation on the closed-cup machine involves the use of plates that are mounted inside the ink container vertically rather than horizontally. The plate rises straight up out of the container, with a doctor blade at the top scraping ink from non-image areas as well as sealing ink in the container from solvent evaporation. The pad moves horizontally to pick up the image from the plate and, depending on the application and the machine design, rotates either 90° or 180° to deposit the image on the substrate. The ink/solvent mixture is nearly as stable as in a closed-cup system, but larger areas can be printed (up to 5 x 18 in. or 12.7 x 45.7 cm).

One additional benefit of sealed inking systems is this: They reduce the level of solvents that are exposed in the working environment and expelled into the atmosphere.

Reciprocating-plate machines

Sometimes, machine manufacturers will opt to keep the pad on the same vertical plane rather than have it move back and forth from plate to substrate in the conventional manner. The plate has to move out of the way for this to happen. Manufacturers accomplish this by using reciprocating plates (Figure 5) that work much like reciprocating-table screen-printing presses. This machine design is available with either closed cups or open ink troughs. Depending on the machine, the ink trough may be shrouded at rest or for half the cycle during operation, helping to maintain the solvent balance.

The single-plane pad movement in this machine provides a cost saving for the manufacturer because the machine has one less actuation. From the user’s point of view, because the pad only has to move in the vertical plane, it vibrates less and the machine can cycle faster. Automatic loading can take advantage of this rapid cycling.

One application for this system is high-speed coding, with machines that some manufacturers claim run at speeds up to 10,000 cycles/hr. Here, a small plate is used with a sealed ink cup. Larger machines with plate areas of 8 x 18 in. (20.3 x 45.7 cm) have been produced using this method, but they need very substantial bearings to support the plate in the pickup position because of the considerable loading pressure exerted by a large pad.

Manufacturers claim that because the pad strokes below the base of the machine, it has a larger work area. The downside to this is that the machine must be well guarded because the forward movement of the plate can potentially be a severe hazard.

Other machine types

(Editor’s note: The Pad Printing Technical Manual contains complete information about a variety of specialty and industrial machine types. We have condensed this information in this section due to space limitations.)

Rotary pad-printing systems These machines use a rotary, drum-type silicone pad in conjunction with a steel cylinder plate. The design is etched into the cylindrical plate, and the ink flows onto it from an ink trough or ducts. A doctor blade removes the excess ink. As the cylinder rotates, the silicone rubber roller picks the ink out of the etching and transfers it onto the substrate.

Developed directly from gravure printing, these machines are very suitable for cylindrical parts and continuous flat printing. Speed is one advantage of rotary pad printing. With small components such as bottle caps, 120,000 parts/ hr can be achieved. Another advantage is that very fine detail can be printed.

Ink deposits tend to be slightly less than in conventional pad printing, particularly at higher speeds. Also, the ink must be run with high levels of solvent. Controlling the solvent balance is essential; we recommend using ink pumps to maintain the ink conditions. Remember that changing colors requires purging the pumps, which is why we do not recommend this approach for short runs.

The cost of rotary systems is relatively high because a feeding system is almost always necessary. Output levels keep the cost per print extremely competitive. The quality should be as good as, if not better than, conventional pad printing.

Total color machines This technique, used almost exclusively in ceramic decoration, combines pad and screen printing. Instead of being etched into a cliche, the image is screen printed onto a flat, silicone-coated plate, where the ink “rests” rather than adheres. Then the silicone pad picks up the ink and transfers it to the substrate.

When this process was first developed in the 1950s, the ink was cold. This did not allow for total transfer, however, so thermoplastic ink was used. This ink, solid like a wax at room temperature, is heated on the metal screen mesh by an electric current, causing it to melt and flow like conventional ink. The pad lifts the ink from the silicone plate and transfers it to the ceramic substrate, which chills the ink and allows for a complete transfer. This technique combines the best of both processes: You can place heavier deposits of ink than can be pad printed onto complex shapes that can’t be screen printed. The heavier deposit ensures high-quality prints while allowing a full range of design effects, from solid lines to halftones.

Carousel machines These novel multicolor pad-printing systems (Figure 6) are designed around a combination of two rotating tables and a rotating pad carousel. Substrates are mounted on one table, while the plates (each inked by a sealed cup) are mounted on the other. The pad carousel and plate table rotate in sequence, so that as one pad deposits a color on the substrate, the pad for the next color is picking up ink from the corresponding plate. This sequence continues until all colors in the image have been printed, then the rotary table is indexed. The printed piece is removed and replaced with an unprinted part.

The cam-operated system is fully mechanical and can print up to 250 four-color designs per hour. Setup is quick and easy, and different pad shapes can be accommodated. Carousel machines can be particularly useful for subcon-tract printers who are often faced with shorter runs of multicolor images.

Vertical machines Applications seldom call for printing onto surfaces that are vertical or angled; however, machines are available that are ideally suited for such work. The print angle on such equipment can be altered up to 90°. Some machines will even print upward. This equipment is often used in conjunction with conventional machines in marking applications, printing the sides of the part while other machines are printing on the top.

Computer numeric control machines With all of the other machine styles, the print station is fixed and parts are fed from one station to the next to achieve a multicolor print. Not so with a machine that uses computer numeric control (CNC). Here, the substrate is stationary and the pads are programmed to print one color at a time.

Though the robotic action of these machines appears complicated, CNC allows for simple setting procedures and enables several setups to be programmed into the machine. The printing action is very smooth, pad-stroke lengths are infinitely variable within the dimensions of the press, and the servo-driven machines aren’t affected by fluctuations in air pressure. Print rates with CNC machines will not necessarily be higher, but downtime and setup should be greatly reduced.

CNC machines are often used when printing must be done in line with other assembly processes. They are so flexible that they come close to being the ideal machine for a particular application, but they are more expensive than conventional pneumatic machines.

Machine extras

Most manufacturers provide a variety of add-ons for their machines. We are not talking about handling and feeding systems or treating equipment, but devices that improve print quality.

Pad cleaning These systems use adhesive tape dispensed onto a platform. The platform is placed under the pad at programmed intervals. When the pad comes down onto the tape, any dried ink or debris on the pad surface is removed. Used mainly on unmanned machines, automatic pad cleaning is generally considered to be a useful addition. But if the substrates are clean, ambient conditions are controlled, and the ink is mixed correctly, automatic pad cleaning could be considered a luxury rather than a necessity.

Ink pumps The concept is to have a reservoir of ink in a closed container. Ink is pumped from the reservoir into the ink trough, then back again to the container. In some cases, solvent is fed into the reservoir as regulated by automatic viscosity-measurement instrumentation. These devices are notoriously unreliable, so it’s better to mix a specific amount of solvent in at the start of the run and add a controlled amount during the run.

Cleaning these systems is a problem. The reservoir must first be emptied and then the pipes have to be flushed out. Even if the ink is never changed, the whole assembly must be cleaned out regularly because the ink has a pot life. Two-component inks can only be used with great care and must be changed regularly. Leaving one in for 24 hr would be a very expensive mistake.

One of the simplest ink-feeding systems is a peristaltic pump that takes ink to and from the trough. These systems pump ink by compressing the tube carrying it. The advantage is that the pump never comes into contact with the ink, only the outside of the tube. Flow rate is infinitely variable, and tubing that will withstand aggressive solvents is available.

Solvent dispensers This is a simpler alternative to ink pumps when a low volume of ink is used. These systems dispense a specific amount of solvent at a set interval. Both the amount and time interval can be adjusted to suit the ink and printing conditions. In principle, regularly adding solvent is an excellent concept. As long as the dispensing system is soundly designed, it will go a long way to reducing one of the major variables in the process.

Use great care in selecting a solvent-dispensing system to ensure that the components will withstand the solvents. Also, the spatula must be modified slightly to ensure that the solvent is mixed in im-mediately. In other systems, a slowly rotating cylinder in the ink trough keeps the ink agitated and the solvent well mixed. This technique is also used with some closed-cup systems. Great care must be taken in regulating the flow because the volume of ink is much less, and it is possible to thin the ink too much.

Air blowers The purpose of these add-ons is to assist solvent evaporation from the ink when it is in the etching, on the pad, or on the substrate. This can be achieved by directing air from either a compressed-air line or a hot-air blower. Such blowers must be used with care, and only when ambient conditions demand them.

Static eliminators By its very nature, pad printing generates a considerable amount of static electricity. Silicone rubber is an excellent insulator and the continuous mechanical action of the pad can generate many thousands of volts of static charge. Add this to the static charge that is inherent in molded plastic substrates–especially when they are stored in a plastic bag immediately after molding and removed from the bag just prior to printing–and you have a static cocktail that can cause real printing problems.

A common effect of static is feath-ering, which occurs where the ink tries to jump back onto the pad as it lifts away from the substrate. Before diagnosing static, make sure that the etch depth on the plate is not too deep or the ink too thick. If static is definitely the culprit, you must eliminate it. You can do this by blowing ionized air over the pad and/or substrate to conduct the static electricity away from the print area.

Such static-elimination equipment is basically a series of electrodes in the air stream that are charged with a very high voltage (20,000 – 40,000 volts). These electrodes emit charged ions that give the air its static-elimination properties.

Static is, to a large extent, affected by ambient conditions. Very low humidity is the greatest problem. In some print facilities, humidifiers are used rather than static eliminators to minimize the effect. Recent developments in the silicone rubber used to produce the printing pad have reduced the amount of static generated. Check to see if your supplier carries such pads.

Image recognition The need for image-recognition equipment is increasing as more companies use unmanned pad-printing machines on automatic lines. The CD industry uses this technology extensively. These systems can detect changes in the print of as little as 0.0005 in. (0.0127 mm). They can also sense color changes. Image-recognition equipment can be set up to alert operators, reject components, or stop the machine.

And finally….

Before you purchase a machine, always have several suppliers carry out print trials for you. (Obviously, you must have enough of the part on hand to send to these suppliers–they can’t do meaningful trials on a part that hasn’t been prototyped yet). Give your suppliers sufficient time to carry out these tests, but insist on being there to see the final trials. Unless you are an expert, never accept that “it will get better in production.” If your supplier cannot achieve an acceptable result, it is unlikely that you can. Talk to other people who have purchased from the same supplier.

Finally, don’t think of the machine as a standalone unit. It must fit into your entire production process. Product must flow efficiently to and from the machine. Cleaning, setup, changeover, and all the other factors of actually using the machine in your facility must be taken into consideration. If you follow these guidelines, you’ll have a sound machine in your facility that will provide effective, repeatable results.

Things to consider before you buy

Look for the following criteria when evaluating machines and their suppliers:

1. Good technical support.

2. Sturdy machine construction.

3. Ease of adjusting all machine functions.

4. Enough distance between pad holder and plate to accept a sufficient depth of pad.

5. Doctor-blade holder able to take flexible blades as well as rigid, with a provision that the flexible blade can be set at a shallower angle.

6. A large enough plate area for the pad to fully spread outside the image area.

7. The output rate for prints of acceptable quality (not the cycle time of the machine.

8. Pad dwell, which enables you to adjust the precise speed of pickup and print actions, as well as the speed of the pad stroke.

9. Pickup and print positions that can be adjusted both front to back and side to side.

10. Fast setup and teardown.

11. Cost of spare inkwells, spatulas, pad holders, blade holders, etc.

12. For multicolor applications, the X, Y, and rotational adjustment on each plate.

13. The X, Y, rotational, and height adjustment for the fixture.

14. Easy cleanup.

15. Easy access to all operational parts of the machine.

16. Standard pneumatic, electrical, and electronic components.

17. In-house maintenance plan or service contract.

18. Cost of replacement cups.

19. Ability of cup edges to be re-machined.

20. Good technical support. (We repeated this one on purpose!)

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?