Concept to Construction: A Profile of ECI Screenprint, Inc.

Published

15 years agoon

Thomaston, CT is a small New England town that fewer than 8000 people call home. Its name pays homage to Seth Thomas, a famous clock maker who, nearly 200 years ago, set up shop in what was then called Plymouth Hollow. He often is credited as being a pioneer in the mass production of clocks of high quality and innovative design. Perhaps that’s why membrane-switch producer ECI Screenprint, Inc. finds the old Seth Thomas Clock Co. factory a natural fit for its design and manufacturing headquarters.

ECI Screenprint opened in 1991 with co-owners Edward Cook and Irma E. Diaz at the helm. The business that would become a specialist in high-quality and high-tolerance design, printing, and assembly of membrane switches and related products actually got its start in P-O-P displays and labeling. It was during the first few years of operation that Cook’s background in engineering moved to the forefront at ECI and shifted the shop’s focus to industrial applications.

“It blossomed from the fact that I’m an engineer and I’ve always enjoyed the type of business were I can look at a blueprint, talk to an engineer, and get into details,” Cook explains. “I think that although P-O-P started us off and helped us get going, which was very helpful in the beginning, our emphasis has always been to build usable graphics for industrial applications.”

Rather than dedicate further marketing resources to securing point-of-purchase work, ECI instead made its commitment to membrane switches and placed a full-page ad in the Thomas Register to promote its abilities in planning, engineering, production, assembly, and rapid prototyping and turnaround. Cook says he believes ECI was the first to offer five-day turnaround for high-end membrane switches, including rush jobs from customers who needed fully functional prototypes—a service that helped ECI make a name for itself in industrial screen printing and manufacturing, grow its business, and service valuable accounts in times of economic uncertainty.

Equipment and specialties

AdvertisementECI uses many of the standard screen-printing products available in the marketplace in prepress, production, and finishing. The shop then modifies or upgrades them in house to improve registration and material handling and to minimize operator intervention.

“We have standard flatbed screen-printing equipment. The only difference is we’ve tightened the tolerances. We’ve got heavy duty vacuum beds on them, pin registration, screen registration, so we go from screenmaking where screens are exposed and registered right to the press with very little setup adjustment,” Cook says.

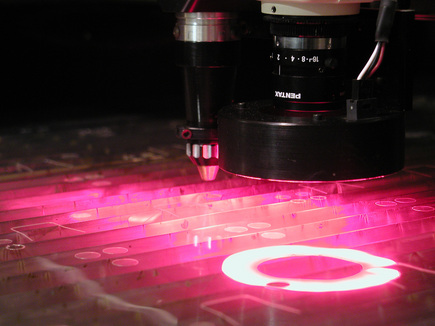

Some pieces of equipment are designed with ECI’s input and custom-made to ECI’s specifications. One example is a large-format, high-speed, precision laser cutter that features video/optical registration and reads fiducial targets with a tolerance of ±0.002 in. (Figure 1). ECI uses the system in the processing of membrane-switch materials—rubber, Mylar, pressure-sensitive adhesives, and Lexan, for example—and related parts, such as gaskets, shims, insulators, and shields.

Digital imaging also is a part of ECI’s services. The company uses a Mimaki UJF-605CII flatbed inkjet printer for prototyping, short runs of labels and graphic overlays, and other projects. It prints a flexible ink from 3M that’s formulated for membrane switches and industrial graphics. Cook says ECI puts the Mimaki to use every day and is honing what he describes as the crossover point from screen to digital.

“There is a definite crossover,” he explains. “There are times when it’s surprising how efficient screen printing is compared to digital. The digital press speed is much slower than screen printing, but you can lay down more colors at once. We find our best solutions for digital involve a lot of multicolor work. A two- or three-color product usually wins out in screen printing. As soon as we hit 200 pieces, it outperforms digital. Digital, on the other hand, really excels at lower volumes because you have less make-ready and setup.”

ECI takes certain jobs to its screen presses, regardless of run size. The company is UL-recognized and is listed for a variety of components. Cook says orders that come in with UL requirements are always screen printed due to strict performance needs and substrate conformance used in the UL-recognized portfolio.

AdvertisementThe shop floor is organized in a modular configuration. ECI’s staff, which includes approximately 20 people, moves particular pieces of production and finishing equipment as needed to maximize the efficiency when working on a job. Machines also can be arranged in such a way that enables one skilled operator to manage the entire production process.

“All of our screen presses, laminators, diecutters, and tables are movable. There’s less handling, and the product comes out ready to go. We’re looking to be lean anywhere we can in production,” Cook notes. “And we can arrange multiple production steps in a round-table format and put one skilled person in the middle to operate all machines on one job and then assemble the product while the machines are processing the next piece. Multiple steps are completed in one phase.”

In addition to membrane switches, ECI’s other specialties include graphic overlays, elastomer keypads, adhesive labels, industrial nameplates, contract assembly, and rush prototypes (Figure 2). ECI is equipped to design and build anything from standalone, flexible, adhesive-backed membrane switches, ready for peel-and-plug application, to projects involving printed circuit boards and metal backers with standoffs, hardware, connectors, surface-mount components, and membrane switches built on top.

Cook says keeping so many products and processes in house allows ECI to run as efficiently as possible and makes scheduling easier. He notes that, with the exception of raw materials and select components, ECI keeps its reliance on outside suppliers to an absolute minimum.

ECI is a Duraswitch licensed manufacturer. Duraswitch invented a magnetic-armature switching system. The company patented its design of a floating armature that is attracted to a magnet that resides above the circuit level. When a machine operator presses the armature, the armature breaks away from the magnet and closes the circuit. Cook says Duraswitch is a highly reliable product that has a very long life time.

“I find it the technology performs really well in specialty applications where you have need large keys, for somebody who wears gloves, or in a high-reliability or high-liability situation like medical devices, where failure is not an option. There are many interesting uses for it.”

AdvertisementECI was one of the first licensees to produce the product under Duraswitch’s patent. Cook explains that Duraswitch controls of the type of product being manufactured, supplies the armatures, and works with ECI to review designs.

Assembly

“Wherever the unit is plugged in is where I stop,” Cook says. However, ECI is capable of handling each part of the process from conception to finished product (Figure 3).

“We do a lot of value-added assembly for customers, where the customer provides sheet-metal backer, or we’ll procure the backer and do that assembly. A lot of customers don’t like to assemble graphics, and we are experts at doing it,” he explains. “We have products where the printed circuit board and metal backer are combined as one unit to be more economical, and we also do elastomer silicone-rubber keypad assemblies, and so on. It’s kind of a smorgasbord of different kinds of assemblies. We do in-house soldering, pick and place, Surface Mount Technology component installation—all the peripheral items you need to do for membrane switches and some for the other assemblies.”

ECI assembles a variety of products, from switches that have flex tails with connectors to injection-molded housings and bezels with membrane switches sometimes assembled with displays and LEDs or backlighting. The customer gets the entire front fascia, assembles it to their enclosure, plugs it in, and it’s done. As cook puts it, that’s where ECI stops.

“We do a lot of work for contract manufacturers who build entire OEM units,” he says. “We’ve got a relationship with a half dozen contract manufacturers, especially in the New England area, where they’ll get jobs from all over the world and, because they have a relationship with us, they know that even if it’s an existing product they can show the product to us and we can reverse-engineer anything and usually save them quite a bit of money, so it helps them win jobs.”

Part of Cook’s decision to develop ties to local service providers stems from his passion for keeping as much business in America as possible. He says local sourcing and working with vendors in the area not only helps the US economy, but face-to-face interaction also enhances customer service, saves on shipping, and allows better management of overall quality.

Business in a rough economy

Can any business be recession-proof? Perhaps not, but Cook says that the market ECI serves isn’t completely drowning in financial gloom and doom.

“We’re kind of a unique market. We’re not just screen printers—we have to be manufacturers,” he explains. “We’re literally a job shop, a manufacturer. We must have standards and many systems and procedures in place to efficiently produce this kind of work.”

Slowdowns at ECI come when the economy compels customers to cease buying all of the parts they need at once. Cook says those who would normally order 2000 pieces might only buy 200 one month and then call in an order the next month for another 200.

“They’re kind of just hedging—holding back,” he observes. “We’re seeing the shift where they’re ordering in little bits and pieces. Some customer have dropped way off, but it depends on the industry. I’ve seen more of that kind of trend where it’s a smaller order with quicker turnaround.”

Cook’s experiences may be unique, but his results dispel the notion that when the going gets tough, the tough always go to China. In his estimation, China has gotten better about serious quality issues over the last 10 years because the Chinese have learned through error what they need to do; however, some issues with consistency linger.

“Their quality has started to level out…but the main thing is to grow our economy and keep it here—keep it local. Some high-volume applications are definitely more suited for production in China; however, ECI produces millions of parts competitively and with a very high quality standard,” he says.

Industry contributions

ECI is involved in a life-cycle-quality study in cooperation with the Specialty Graphic Imaging Association (SGIA), in which suppliers and manufacturers in the membrane-switch and printed-electronics industries use a controlled study to identify best practices and materials for extending the longevity of the products in which they specialize.

Cook is vice-chairman of SGIA’s Membrane Switch Council, which serves as a steering committee for its market segment. Its purpose is to provide resources such as educational opportunities and information to OEMs, suppliers, producers, and buyers.

“I really enjoy that kind of work,” Cook says. “We organize presentations for the Membrane Switch Symposium, and a common thread over the years has been that each company has its own techniques and procedures for producing switches and printed electronics—but which ones work better than others? No one ever really gets it all together, because you have different environments, locations, techniques, and technologies. In the marketplace, no one knows the difference. So we’re trying to analyze some of these nuances through this testing.”

The study is in its second phase. The first round of testing involved surface-mount-component application to flexible circuitry. ECI did the printing and surface-mount assembly, and industry vendor Nicomatic handled all of the testing. Phase two centers around the use of different conductive materials and different dielectric or insulating materials, combining them in multiple ways all on one printed sheet, and then conducting lifecycle assessments and aging tests under the care of Don Banfield, founder of Conductive Compounds.

“ECI is participating by printing the product. There are two other printers in the US in different locations who have printed the same pattern. ECI is doing all the assembly, and then we’re sending that over to Don to test different places on the patterns to measure breakdown and other factors.”

Cooks explains that the group’s goal isn’t to establish standards. ASTM already has standards for membrane switches that include a variety of switch types and methods for testing. Instead, the study aims to identify which processes and materials are most compatible and hold up best in producing membrane switches.

“We’ve got different types of materials out there, different types of conductive materials—not just brands, but actual resins and compounds. They’re used kind of carte blanche across the board. Some are better than other in certain applications,” he says. “We’re trying to prove some of those things out, because each company thinks its way is the best way. Don’t we all? If you pick through it, a lot of manufacturers do things in a similar way, but without testing they don’t really know which method performs better than the other and why. This is a blind test. We have three different companies printing the same thing, and no one knows who’s who. Each just sends its samples in for testing, and you come up with some data. It’ll be shared with the society, and we hope to find useful details that printed-electronics manufacturers may find useful and interesting.”

The secret to ECI’s success

Collaborating with customers is a major part of ECI’s culture and is one that is a significant contributor to the business’s growth. A customer who brings an idea or a project to ECI is first involved in what Cook calls a design interview. Cook joins ECI’s estimator, a customer-service representative, and a designer to meet with the client and discuss ideas, goals, and expectations. Attempting to understand the customer’s wants and needs is a critical step in the design process.

“It might be they don’t like the color blue—something as simple as that,” he says, “or maybe they’re trying to put too many things in a small package and we can foresee problems that may not surface immediately. Those are the challenges we love. Sitting down one-on-one with the customer is the best scenario because many times we get design drawings that are complete and released, which makes it very difficult at that point to get the customer to go back and change things.”

Cook’s preference is to get in on the ground floor with customers. As he explains it, the product always comes out better and is less expensive.

“There’s always something we catch or can show them,” he says. “That’s what makes us excited to get up in the morning and do this. It’s all about the new products, the new ideas, and the innovation. That’s the fun part of our business.”

Cook stresses that all of the company’s achievements—from relocating to a facility 15 times larger than the one in which ECI started, to enjoying double-digit growth for the past five years—rest on a foundation of solid customer relationships. And that’s one thing he says will never change.

“We’ve done a lot of interesting projects over the years. From the beginning until now the focus hasn’t really shifted, and that’s heavy customer service and a get-it-done attitude, where you do everything possible to complete the job for the customer. We built the company on that, and we continue to do so to this day.”

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

Advertisement

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

Livin’ the High Life

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?