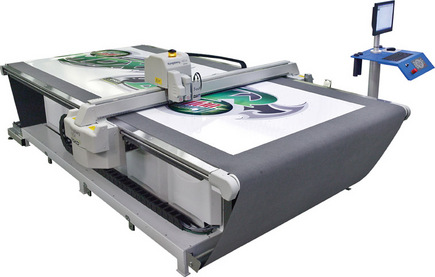

Mikkelsen Graphic Engineering (MGE), in conjunction with the Kongsberg Division of EskoArtwork, has developed the i-XE series of cutting systems to reduce turnaround times and enhance finishing accuracy. MGE says the i-XE line offers the most flexibility, precision, speed, and effectiveness for processing roll-fed, flexible and semi-rigid substrates, eliminates print/cut misalignments, and minimizes waste. The cutters may be used to finish graphics that are screen or digitally printed.

Cutters in the i-XE series come in three models. The i-XE10 accepts rolls of media up to 36 in. (914 mm) wide and can cut roll-fed sheeted materials in an area up to 31 in. (787 mm), and has a working area of 31 x 43 in. (787 x 1092 mm). The i-XE10 operates at speeds up to 52.5 in./sec (1.3 m/sec) and can accelerate as quickly as 1.2 G (12 m/sec2).

The i-XE32 accepts rolls of media up to 53 in. (1346 mm) wide and can cut rolls or sheets of materials. It accommodates a maximum cut-sheet size of 57.1 x 66.9 in. (1450 x 1699 mm) and has a maximum working area of 53.1 x 63.7 in. (1349 x 1618 mm). The i-XE32 operates at speeds up to 47.3 in./sec (1.2 m/sec) and can accelerate as quickly as 1 G (9.6 m/sec2).

The i-XE54 accepts rolls of media up to 66.1 in. (1680 mm) wide and can cut roll-fed and sheet-fed materials in an area up to 63 in. (1600 mm). This machine has a working area of 63 x 120 in. (1600 x 3048 mm). The i-XE54 operates at speeds up to 47.3 in./sec (1.2 m/sec) and can accelerate as quickly as 1 G (9.6 m/sec2).

Each machine in the i-XE series features MGE’s i-cut Vision Pro system, which is designed to compensate for all linear and non-linear material/print distortions. It includes software integrated into the cutting-tool head and a CCD camera that reads registration marks and bar codes that are printed along with the graphics. These marks are either positioned manually by the prepress operator or automatically by the RIP or by ai-cut, a plug-in for Adobe Illustrator software that also preflights each file to eliminate setup errors. The ai-cut plug-in is available as a free download from MGE’s website.

MGE i-script was developed to integrate printing and cutting instructions, add critical commands, cut-contours, print-job nesting, bar codes, and registration-mark-positioning information to automatically process jobs. It has been adapted by RIP and printer manufacturers such as 3M, Caldera, EFI VUTEk, Durst, Ergosoft, Esko Scope, HP Indigo, Onyx, Wasatch, and others. MGE says may of these RIPs will also shortly incorporate intelligent register marks in position for the graphics automatically, eliminating the need for ai-cut when such RIPs are used.

The i-XE cutters are built with rack-and-pinion motor drives and multi-axis servo drive systems designed for quick acceleration and full-speed operation without loss of precision. Software-controlled blade pressure enables the i-XE systems to kiss-cut or through-cut at forces up to 20 kg. An optional glide shoe allows cutting of a variety of materials. The cutters can process a variety of materials, from carton board, polycarbonate, and single-flute corrugated board to fibrous materials, fabrics, technical textiles, and more. They accommodate materials up to 0.25 in. (6 mm) thick.

Systems in the i-XE line also feature MGE’s Auto-Feeder, which is designed to handle up to three stacks of printed graphics on materials ranging from thin films to papers to thick board stock loaded simultaneously to minimize setup time and further automate cutting. All i-XE cutters can also be tooled for pen plotting, scoring, creasing, and oscillating. For more information, contact Mikkelsen Graphic Engineering, Inc., 801 Geneva Pkwy., Lake Geneva, WI 53147, 262-348-0400, fax: 262-348-0500, e-mail: info@mge-us.com, Web: www.mge-us.com.

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month ago

Case Studies1 month ago

Case Studies1 month ago

Andy MacDougall1 month ago

Andy MacDougall1 month ago

Editor's Note1 week ago

Editor's Note1 week ago

Columns2 weeks ago

Columns2 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Marshall Atkinson1 week ago

Marshall Atkinson1 week ago

Press Releases2 months ago

Press Releases2 months ago