Articles

Dana Corp.: Where Autos Motivate High-Performance Screen Printing

Published

24 years agoon

Your car engine growls to life. Within moments, pistons, pumps, cranks, and cams gather speed, converting fuel to horsepower and sending lubricants and combustion gases coursing through the engine’s interior. As the machine builds power, pressures within reach crushing levels while temperatures escalate to searing highs.

Struggling to break free of their mechanical constraints, these enormous stresses continually search for weak links between engine components. And the only thing keeping them from tearing through the sensitive connections are thin sealing systems known as gaskets. As you might expect, creating gaskets that can withstand torturous engine forces is an engineering challenge. But in some cases, it’s a challenge that’s been surmounted with the aid of screen printing.

To learn more about this unique application, Screen Printing magazine hooked up with the world’s largest producer of engine gaskets, the Victor Reinz division of Dana Corp., to tour its manufacturing plant in Danville, KY. Here, screen printing is a key element of a gasket-production process that has won the company such clients as Nissan, Ford, GM, and Caterpillar, to name a few. Although Dana carefully guards its propriety production methods, our hosts graciously shared some of the secrets behind this challenging industrial application for screen printing.

What is a gasket?

Whether they drive lawn mowers or locomotives, engines comprise hundreds of parts in an assortment of shapes and sizes. For an engine to operate properly, these components must mate together tightly to maintain lubricant and coolant levels and prevent air, water, and other external contaminants from entering combustion chambers and other critical areas of the system.

AdvertisementBecause engine parts can expand and contract at different rates, and are subjected to varying levels of stress at their connection points, they require flexible and durable sealing components that can conform to these changing conditions without sacrificing the tight connection. Enter the gasket, which may be a single material or a composite of several materials that fits between the parts and ensures that they are strongly sealed.

In some engine areas, a simple rubber or metal gasket may be sufficient. But deep in the bowels of a car engine, where heat, pressure, and material expansion are most prevalent, a simple gasket just won’t do. Normal operating conditions can weaken the part to the point of failure. So manufacturers like Dana have developed composite gaskets that utilize special metal alloys, facing materials, and engineered coatings to withstand the harsh environment and maintain a tight coupling between engine components.

Composite gaskets are manufactured to match the application requirements. For example, an oil-pan gasket on a lawnmower needs to provide far less pressure resistance than a head gasket on a 30-ton bulldozer. The demands on gaskets within the same vehicle may also be vastly different. For example, an exhaust manifold gasket on a car engine requires resistance to much higher temperatures than on the intake manifold. Other composite gaskets are engineered to resist specific fuels and chemicals they will contact, such as propane, diesel fuel, alcohol, or transmission fluid.

Regardless of their construction, all gaskets must provide some degree of temperature, pressure, and chemical resistance. They must be both compressible and resilient so that they can adjust to shifting part positions when the engine cycles, as well as load variances (pressure exerted by bolts and similar fasteners) caused by expansion or contraction of the joined components. Additionally, they must provide radial strength to help the gasket withstand differential motion between mated surfaces. And most importantly, the gasket must maintain its seal under any and all of these conditions.

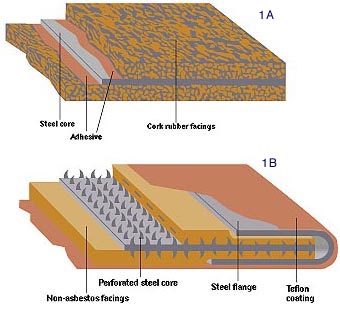

Composite gaskets come in a variety of constructions. One of the most common involves sandwiching a metal core or plate between layers of heat-resistant facing material (typically a cork/rubber material or a mixture of rubber, cellulose, clay, and other ingredients). These layers may be bound to the core with adhesives, mechanically “clinched” to a perforated metal core, or both.

Once the gasket body is complete, it is diecut to the desired shape, featuring openings for mechanical connections and fluid channels between components. Flange lacing and grommet holes may also be diecut or formed on the gasket to enhance its sealing characteristics. The composite may then undergo a flattening process to ensure that it doesn’t exceed a specific thickness.

AdvertisementFor some applications, however, these materials and manufacturing methods are still not enough. Often elastomeric coatings must be applied on gasket surfaces to further enhance sealing characteristics. This is where screen printing comes into play.

Screen printing’s contribution

As the previous description pointed out, automotive gaskets generally comprise more than a single layer of material. As Figures 1A and 1B illustrate, most resemble a “cake” with layers that include a metal core, facing material, and frequently, a Teflon or polymer layer that prevents sticking. For critical components, these layers may be topped off with a screen-printed “icing” (or “bead”) that consists of a specially-blended coating. The beads typically appear near the gasket’s perimeter and around openings in its center (Figure 2).

“The basic hard gasket material and the specialized coating comprise a unitized system,” explains Dan Boggs, process engineer at Victor Reinz. “The gasket fails completely if either component is altered without regard to the other.”

In the past, elastomer coatings might have been applied by hand. But to meet today’s exacting specifications for engine construction and production efficiency, a faster, more precise, and more repeatable application method was required. So engineers began searching for a technique that could rapidly deposit virtually any coating rheology onto almost any surface at a wide range of thicknesses; a system where coating thickness could be precisely controlled and accurately repeated on millions of parts. They settled on the only method that could meet all these requirements–the screen-printing process.

For Dana’s Victor Reinz division, one of the most important benefits of screen printing is its ability to deposit a precise and deliberately uneven coating height in one printing pass. In other words, the coating bead is purposely lopsided, with one end noticeably thicker or higher than the other. This construction is intended to reinforce the seal in positions where mated parts are more likely to push away from one another unevenly or experience disproportionate stresses. A highly proprietary process, Dana isn’t about to explain how this variable coating height is achieved, other than to say that the accomplishment is born within the screenmaking process.

AdvertisementBesides delivering non-uniform coating thicknesses, the company’s screen-printing process is marked by several other characteristics that set it apart from conventional applications. Most notable is the fact that the printed products are purely functional and are not intended for viewing. Consequently, color control is unknown in the Victor Reinz division’s screen-printing department, and terms like “art,” “separations,” and “moiré” are foreign to its printers. Likewise, you won’t hear the term “ink” used by company personnel–Dana only prints high-performance “coatings.”

Sometimes, the coatings are screen printed onto a silicone-based carrier sheet (Figure 3), dried in an IR dryer (or UV-curing unit, depending on the coating), then transferred to the solid gasket material using another proprietary process. Increasingly, however, the coatings are being applied directly to gasket materials, further streamlining the manufacturing process.

Screen printing at Dana

Founded in 1904 and based in Toledo, OH, the Dana Corp., which manufacturers a wide range of truck and automotive parts in addition to gaskets, operates 270 facilities in 32 countries worldwide and has annual sales of approximately $12.5 billion. Dana’s 85,000-sq-ft Victor Reinz plant in Danville, KY, devotes approximately 2600 sq ft of space to the screen-printing department (although an addition is planned).

Making up an island in the center of the facility, the screen-printing department incorporates three four-post semi-automatic graphics presses (Figure 4), two drying units, and several small cabinets for storing squeegees, floodbars, and rigid-metal screens that all measure 38 x 38 in. (Figure 5). The only other equipment to be found in the relatively sparse department is an automatic squeegee sharpener that shows signs of frequent use. All printable coatings are mixed in a separate area of the facility.

Noticeably absent from the Danville production floor is an artroom, screenroom, and cleaning/reclaiming area. An art department is unnecessary because gasket designs are supplied by another Dana facility or the customer itself. No screenroom is necessary because the facility uses a pair of outside contractors, which stretch, coat, and expose screens with the required images, then send them to Dana ready for printing.

As for screen cleaning, this process is handled right on the production floor and, occasionally, right on press. The screens are wiped clean with special solvents after a job is completed, then returned to the storage cabinet until they’re needed again. If a screen is damaged or a particular gasket design is discontinued, the screen is simply returned to the contractor.

Running a screen-printing operation that relies on outside contractors is a lot like packing your lunch for a field trip: You must know what screens you’ll need long before you actually need them, keeping in mind that you have limited space to store your items and no resources to make screens on your own.

“We’ve got to make sure we keep a certain number of screens for every part number in house,” Boggs says. “If we fall below a certain minimum, word makes it back to me that we need more screens, and I place an order. How fast the screens wear down determines how many of the same screen we keep in house. Some parts are more forgiving on the screens than others, but some parts are tough on the screens, so we keep more of those screens. We check screen counts and quality a few times per week, insuring that the plant has adequate screen resources for the jobs to be done later. We’ve got to stay on top of this because, as a tier 1 automotive supplier, delaying a shipment to a customer is not an acceptable option.”

When a new screen is needed, Boggs begins the process of ordering the screen from a supplier. First, he prints a copy of the design file. This template shows the layout of the image and the location of the image within the frame. Boggs also prints documentation for the screen supplier that specifies emulsion characteristics, mesh type and count, mesh color, screen tension, and other specifications. The supplier then makes the screen using the original design file and delivers it to the shop.

“When the screens arrive, we evaluate each one visually and confirm mesh count, emulsion thickness and so on,” explains Boggs. “These parameters are all documented on the individual screen. This way, we develop performance histories of all the technical specifications of our screens and monitor supplier quality at the same time. Although we don’t manufacture our own screens, we are technically demanding because our applications are technically demanding. The cost impact of printing our coating a few thousandths of an inch outside of its normal range could be thousands of dollars.”

Each gasket the company produces is manufactured according to pre-established screen and printing parameters, including emulsion thicknesses, off-contact distance, etc.–all of which are thoroughly documented and cross-documented. Day after day, the plant works with the same range of gasket designs, each requiring its own proprietary coating formula. All of Dana’s presses are standardized to run any of its screen-printed products.

During an average production shift, roughly half a dozen employees work in the screen-printing department. However, personnel aren’t dedicated solely to this department. Instead, Dana cross trains all of its gasket makers in multiple operations. So an employee who operates screen-printing equipment one day may be found on a diecutting press or stamping machine the next. This gives the company’s production managers the flexibility to rotate people in or out of specific areas as needed.

To ensure quality throughout the facility and eliminate guesswork, all operations and procedures are documented according to QS-9000 and ISO 9001 standards. “I have charts that say if we’re working with gasket X, then it requires a deposit thickness of Y, so we need to order an emulsion thickness Z,” says Boggs. “The system works extremely well.” Boggs must be right since the relatively small department successfully prints about 2.5 million gaskets per year.

Other oddities

Because the screen-printing department is a small portion of Dana’s Danville facility, printers there face an environment far different from a conventional screen-printing shop. One of the most readily apparent differences is the level of noise. Just a few arms lengths away in any direction from the screen-printing presses are heavy-duty industrial metal-cutting and punching machines, which, when cycling, can slice through silence as quickly as they slice through steel. So all workers on the plant floor are required to wear earplugs at all times.

The heavy-duty cutting equipment also poses another challenge to Dana’s screen printers: The devices create a significant amount of airborne material that is circulated through the plant, including small particles of metal that threaten screen mesh, squeegee edges, and ultimately, ink deposits. One of the hardest-hit elements of the printing process are screen stencils, which not only have to contend with the airborne contaminants, but also face abrasion from the coatings being printed and the gasket materials on which they are applied.

Multiple quality checks are performed every hour to ensure that Dana’s products meet all required specifications. “Our facility has labs equipped with the proper instrumentation to measure certain characteristics of our coatings,” Boggs said. “We also use optical tools to verify part quality, and Dana patented a device to determine the thickness of compressible coatings in a non-destructive way.”

Thriving in the automotive market

In many ways, the stakes are higher for Dana than for companies that screen print display graphics and other more “decorative” applications. For a graphics printer, an occasional misprinted color may be an expensive mistake in terms of wasted material and unhappy customers, but it’s a survival problem. For Dana’s Victor Reinz division, however, a slight variance in coating thickness could lead to faulty gaskets and, inevitably, expensive–and potentially hazardous–engine failures. In the automotive industry, a mistake like that can shut down a company permanently.

That’s never happened to Dana, of course, and the company’s tight documentation, top-notch quality control, and frequent cross checks ensure that it never will. In fact, because of its manufacturing excellence, the Victor Reinz division was honored with Kentucky’s Gold Quality Award in 1997.

Dana’s position as a market leader is fueled by a number of innovative procedures that it can’t disclose due to the highly competitive nature of the automotive and commercial vehicle industry. Among these are sensitive details about its screen-printing techniques. Still, Boggs says, “We might not seem like a typical screen-printing shop, but I think you’d find that we encounter many of the same production problems as other screen printers.”

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

Livin’ the High Life

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?