In its quest to offer the Australian market high quality digital textile printers, New South Wales based specialist supplier DGS has signed a formal agreement with Dutch manufacturer Hollanders Printing Systems to distribute the company’s wide-format ColorBooster 250 and ColorBooster 320 sublimation and disperse systems. These will be complemented by the ColorFix fixation unit and the ColorWash machine which are designed to work alongside the print units to generate optimum colour saturation and overall quality and feel.

In its quest to offer the Australian market high quality digital textile printers, New South Wales based specialist supplier DGS has signed a formal agreement with Dutch manufacturer Hollanders Printing Systems to distribute the company’s wide-format ColorBooster 250 and ColorBooster 320 sublimation and disperse systems. These will be complemented by the ColorFix fixation unit and the ColorWash machine which are designed to work alongside the print units to generate optimum colour saturation and overall quality and feel.

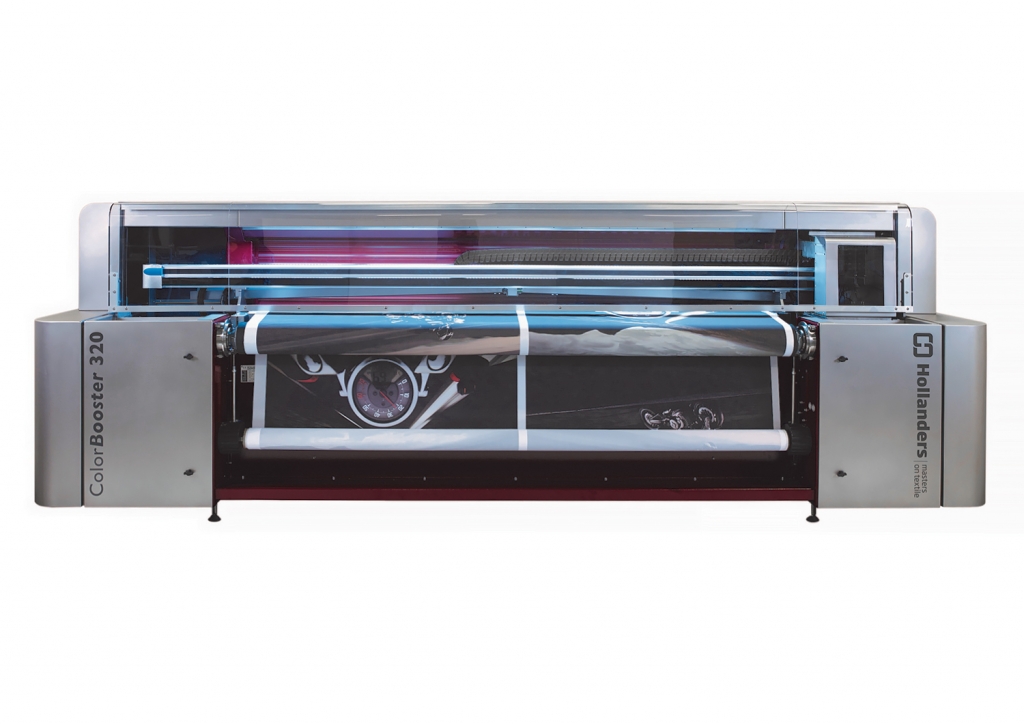

Hollanders Printing Systems introduced its robust yet modestly priced ColorBooster 250 series in 2014 as a 2.5m workhorse printer that is able to produce high quality throughput with a variety of modular options. This machine is now also available in a 3.2m model, designated the ColorBooster 320, which gives users the same versatile configuration choices according to budgetary and production requirements, including numbers of print-heads and colours, and integrated climate and humidity control.

Both the Hollanders ColorFix and ColorWash units are designed using the same ergonomic and rugged construction as incorporated into the company’s printers to generate high quality results across all fabrics and application types. Both independent machines, the ColorFix incorporates middle-wave infra-red energy that provides consistently precise temperatures across the full width of the textile, resulting in high UV resistance, colour vibrancy and durability. The ColorWash is designed to use low levels of water and recycled hot air circulation, and is available in a choice of modular configurations according to end-user needs.

DGS is a well-known supplier of wide-format printers, consumables and accessories in the Australian market, with in-depth knowledge of all ink-jet technologies and application requirements. The company had been looking for a suitable series of rugged and reliable textile production units, and settled on the Hollanders machines after visiting the company’s stand at FESPA in Cologne.

“Australia is a strong growth market for textile print production where users need a robust and dependable platform. They also want to work with a long-standing distributor that is familiar with user requirements in this specific industry segment,” states Rowan Bloemberg, Marketing Manager at Hollanders Printing Systems. “The partnership with DGS is an important step forward for Hollanders and endorses the growing appeal for the company’s products world-wide. The machines are engineered to work in all environments, even those where humidity and temperature can pose a problem for many printing machines.”

Advertisement

Designed to produce high quality soft signs, point-of-sale and retail display applications, the additional refinements that can be made to the ColorBooster 250 and ColorBooster 320 broaden its suitability for all-round textile printing. Starting with a four-colour configuration, accommodating Ricoh MH5420 print-heads, the 2.5m model can be upgraded to six heads with six colours and the 3.2m machine includes eight heads and eight colours for users requiring a wider gamut. Additional options include climate cooling and heating plus humidity and dust control.

The Hollanders Printing Systems portfolio of printers also includes the ColorBooster DS duo of machines, available in two widths of 3.2m and 2.1m which incorporates simultaneous double-sided production and integrated fixation. This system features on-board climate control and enables 24/7 production. The company’s 3.2m ColorBooster XL also retains its position as a leading industrial-strength platform which, again, is designed around a modular concept and can be tailored to suit specific customer requirements.

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month ago

Case Studies1 month ago

Case Studies1 month ago

Andy MacDougall1 month ago

Andy MacDougall1 month ago

Columns2 weeks ago

Columns2 weeks ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks ago

News & Trends1 month ago

News & Trends1 month ago