Graphics Printing

Published

14 years agoon

Screen printing the weird is a great activity, as it puts us in contact with inventive people in our respective communities and offers the possibility of creating whole new revenue streams and opportunities should an idea take off. My client got a unique product that exceeded expectations, but she might be on to something that could potentially bring economy and jobs to remote native villages dotted along the jagged Pacific shoreline of Vancouver Island.

Screen printing the weird is a great activity, as it puts us in contact with inventive people in our respective communities and offers the possibility of creating whole new revenue streams and opportunities should an idea take off. My client got a unique product that exceeded expectations, but she might be on to something that could potentially bring economy and jobs to remote native villages dotted along the jagged Pacific shoreline of Vancouver Island.

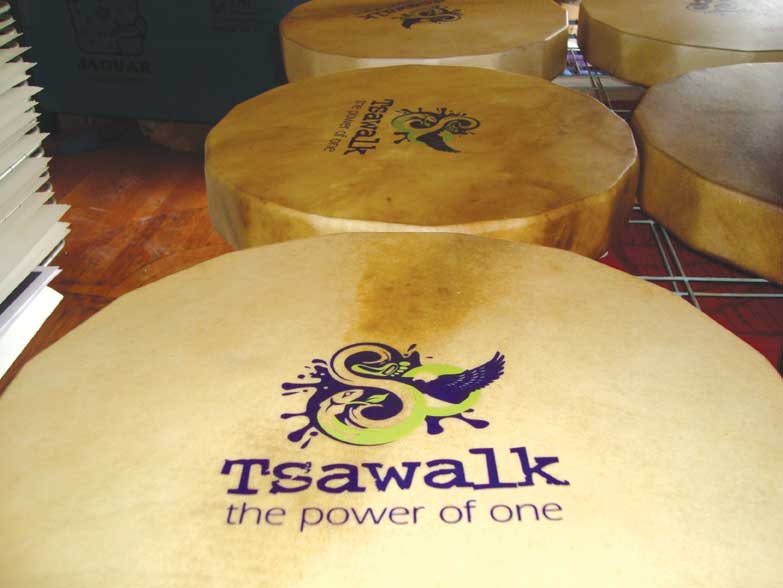

The challenge was to print a two-color logo onto deer hide. The skin had been scraped and was stretched and laced with rawhide over a traditional drum frame made out of wood, approximately 3 in. thick and roughly 15 in. in diameter. I say approximately and roughly because the 15 drums were all made mostly by hand. The trap on the print was about 1 pt. Not your normal job. Not your normal material.

I did some testing and found a water-based ink that worked fine on the skin. I separated the artwork, made films, and made stencils on 230-thread/in. mesh, which gave us a good edge and ensured enough ink laydown to cover any surface irregularities. I then set the job up on a small, table-mounted, manual press with height-adjustable hinges.

I usually work with a circular jig or two edge pads when I print round objects. The first color down is a small tick near the edge that’s used to align subsequent colors to the index mark on the jig. In this case, the image was way in the center, the drums were not perfect circles, and we didn’t want to run the risk of wrecking drums while setting up the second color. The client supplied just enough of the expensive drums for the print run, so there was no room for error.

Background material

A little background on my client and the drums: Kelly Poirier is a member of the Nuu-chah-nulth First Nations, a group of 14 tribes whose traditional lands stretch up the west coast of Vancouver Island. Many of the villages are only accessible by boat or floatplane. Many people in those villages have struggled with economic hardship since mismanagement of salmon populations wiped out traditional fishing jobs.

Kelly and her team at White Raven Consulting (www.whiteravenconsulting.ca) are all university graduates and hold degrees in fine art, graphics, anthropology, business, creative writing, and journalism. They provide a range of graphic-design, communication, and economic-development services, from logo and exhibit design to Website development, reports, and conferences. White Raven Consulting is a unique agency in that its members incorporate Nuu-chah-nulth values, traditional knowledge, and cultural sensitivity into their day-to-day business dealings.

White Raven had assisted in putting together an accord between native groups and businesses that created a best-practices guide to help save and strengthen the wild salmon that are found in the waters of Vancouver Island. As a way to mark the stakeholders’ agreement, they came up with the idea of putting the Tsawalk Partnership’s logo on traditional ceremonial drums and then had all of the associated people sign the drums. The drums were displayed in each business or band office to cement the agreement, reminding all parties that they’re one with the earth and the salmon and each other. And the drums looked cool! These were no $5 engraved MDF wall plaques.

Back to printing the drums. Now, if this were a big production run, I would have spent some time to make a proper nesting jig and work out the details for indexing the second color. I would have also asked for some extra drums for setup—just in case. But these were prototypes, and extras were not available.

Applying screen-printing techniques

I got some masking tape, registered each drum into two pads stuck to the table top, and placed the masking tape under the two bullseyes on the screen. I printed the first color, making sure I also hit the registration marks and that they printed onto the tape. I then moved each drum until the bullseyes on the tape aligned with the ones on the screen, printed the second color, and peeled the tape away after the print. The graphics looked great, registration was tight, and the printing went quickly.

Here’s the neat part: Kelly made some inquiries at a number of galleries in Victoria and Vancouver and found out these types of drums retail for $350-600, depending on the art. Collectible drums are hand painted, which limits availability and prices them out of the souvenir market. She found a wholesale drum maker to produce the blanks, and we worked out a simple method of multicolor printing that yields flawless results. Better still, the whole project requires very little startup capital, uses local art, and provides work and income for people in need. The drums should be in production by the fall.

What a great example of traditional culture mixed into arts-based business development—with a dash of creativity and a cup of screen printing. Let’s bang on that drum!

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?