Digital Printing

Published

17 years agoon

Not long ago, the perception was that screen printing and digital inkjet printing represented two distinctly different worlds: Screen printing was for high-volume, lower-resolution work and inkjet for low-volume, photo-quality images. Today, the worlds are converging as screen printers are discovering that the latest inkjet technology can improve the efficiency, productivity, and profitability of their businesses while expanding the range of applications and types of customers for whom they print.

What are flatbed UV inkjets?

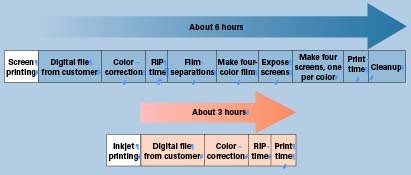

Inkjet equipment has become widely known for efficient, high-quality, multicolor printing on flexible substrates. "Industrial grade" systems now print at speeds up to more than 4000 sq ft/hr, and some offer resolutions exceeding 1000 dpi. One of the most appealing aspects of inkjet technology among screen printers is that it eliminates many of the setup tasks that make screen printing impractical for short production runs (Figure 1).

Flatbed inkjet equipment using UV-curable inks takes these advantages and makes them applicable to all of the rigid materials screen printers use on a daily basis, including those listed in Figure 2. It also allows shops to print on numerous materials they may never have dreamed of using before, such as metal, plywood, and glass. Additional benefits of UV flatbed technology include ease of use, quick changeover of jobs and materials, low maintenance, and high reliability.

High-quality flatbed UV inkjet printers are capable of handling both rigid and flexible media up to 6 ft (1.8 m) or more in width (Figure 3). They allow for fast automated and semi-automated change-overs to materials of different thicknesses and widths and may include tight integration with sophisticated automated finishing equipment, such as cutting plotters. Of course, this ability to handle materials of varying sizes is not useful if the inks do not adhere well to them. This is where UV-curable inks come in.

The setting and subsequent adhesion of UV-curable inks is triggered when they are exposed to an ultraviolet light source during the printing process. Management of this UV light source gives users a wide range of control over the ink-curing process, something that is not possible with solvent-based inks. UV-curing variables include intensity and wavelength of the light and duration of exposure.

Figure 2 Material Compatibility

The list of substrates supported by flatbed UV inkjets mirrors the range of materials that screen shops typically use. This list identifies some of the most common, along with the estimated percentage of total substrate use each type of material represents in an average graphics screen-printing company.

| Material | Estimated percent of total material use

|

| Pressure-sensitive vinyl | 22% |

| PVC (flexible) | 7% |

| Styrene/ABS | 10% |

| Polycarbonate/Lexan | 12% |

| Foam/corrugated board | 4% |

| Card stock/ paperboard | 9% |

| Metal | 11% |

| PVC (rigid) | 5% |

| Polyethylene | 4% |

| Polyester/Mylar | 9% |

| Acrylic/Plexiglas | 4% |

| Polypropylene | 3% |

"Tweaking" UV-curing parameters makes it possible to get inks to adhere well to a broader range of materials than screen printers have used in the past with a single ink set. The four-, six-, and eight-color ink sets typically available on flat-bed inkjets are matched to the printing equipment for optimal performance and excellent color-matching capabilities. It is interesting to note that many screen printers new to inkjet mistakenly believe that the single ink set is a limitation. Actually, it is an advantage because it allows for consistent quality, faster changeovers, and reductions in ink inventories.

In any event, now that flatbed UV inkjet printing is applicable to the full range of materials used routinely by graphics screen printers, it is only reasonable to evaluate the impact this technology might have on their business operations.

Core business enhancement

Depending on whom you talk with, screen printing can be the process of choice for print runs ranging from 25-1000 pieces or greater. Whatever the case, a flatbed UV inkjet printer can make significant contributions to the profitability of the screen printer's core business. The following sections describe how:

Short runs Flatbed UV inkjets are well suited for multi-market product rollouts, in which relatively small quantities of multiple campaign elements must be delivered to specific markets on short notice. They also are perfect for addressing the smaller-volume print needs of local retailers and other display-graphics customers.

Proofing Waiting for customers to sign off on press proofs can keep a screen-printing line idle for hours, if not days. An equally unattractive possibility is setting up another job if a long wait is anticipated. But flatbed UV systems can print one or several proofs without incurring setup costs.

Even better, new digital technology makes it possible for the inkjet printer to shed its characteristic random (stochastic) dot pattern, which gives the illusion of a tighter image with more diffused tones, and produce a halftone (rosette) dot pattern that looks very much like what the screen-printing customer is used to seeing (Figure 4). This makes it possible to calibrate the flatbed UV printer to the screen-printing system so that the inkjet proof closely emulates the finished screen-printing product.

$image

Customized prototypes The same logic that makes flatbed UV inkjets so suitable for short runs and proofs also makes them ideal for creating prototypes. Flatbeds allow printers to keep their screen-printing lines dedicated to higher-volume runs and avoid the inefficiencies of frequent setups and teardowns.

Making up for short falls Many screen printers know from experience that customers often require more pieces than they initially order. As a hedge against the painful prospect of asking the customer to pay for a new setup (or eating the cost), many printers inventory additional prints. This practice, of course, has its own unwanted costs. Making up for shortfalls with inkjet prints solves this problem.

Avoid subbing To satisfy a good customer or maintain control over a multi-element project, many screen printers get involved in contracting out short-run photo-quality work. This may result in loss of control of the project timing and product quality, as well as reduced profitability. With flatbed UV inkjet technology in house, the need to contract out your work can be dramatically reduced or eliminated.

Stretch current screen-printing capacity If your screen-printing capacity is stretched to the limit, there are many tasks, such as those described above, that can be profitably offloaded to the flatbed UV inkjet system. This can make it possible to postpone the purchase of an additional screen-printing system.

Pursuing new opportunities

Once you acquire a flatbed UV inkjet system to realize core business advantages, it makes sense to explore other "out-of-home" opportunities that make it possible to expand your business into new areas, many with higher profit potential. These applications may involve fast turn-around, lower volume, high-quality printing of graphic images for P-O-P displays and signage, as well as completely new applications with packaging and decorative elements. Some of the potential applications that can be addressed with flatbed UV inkjets are listed in Figure 5.

The broader graphic-printing capability and material options afforded by flatbed UV inkjet technology also give the screen printer an expanded set of tools for solving more of his existing customers' problems. For example, the ability to print on unique materials (ceramic tiles, for example) may allow the customer to create unique marketing materials. Lenticular prints (images that flip as you change your viewing angle) are another example of a unique application that flatbed UV inkjets can readily handle.

Flatbed UV inkjet technology also holds promise for the large numbers of screen printers who are manufacturing high-volume products, such as wallpaper, flooring, counter laminates, and other building materials. The quality and steadily improving versatility and speed of this technology makes it possible for producers of these products to create unique, high-profit, custom materials or dramatically reduce the cost of making prototype samples.

Figure 5 Out-of-Home Display Graphics Opportunities

Out-of-home media once consisted mainly of bulletins and posters but now represent an ever growing range of applications that flatbed UV inkjet printers are well-suited to handle. Here are but a few examples:

| • in-store displays | • barrier poles |

| • stadium and arena displays | • blimps and custom inflatables |

| • trackside advertising | • carton advertising |

| • shopping mall displays | • gas nozzle advertising |

| • interior and exterior bus/transit posters | • golf practice range divider advertising |

| • airport terminal displays | • marine vessel displays |

| • bus bench panels | • parking meter advertising |

| • billboards | • place-based displays |

| • wall murals | • postcard advertising |

| • kiosks | • rest area panels |

| • pedestrian panels | • trash receptacle panels |

| • taxicab posters | • turnstile advertising |

| • airborne displays | • vending cart umbrellas |

Questions and answers

To further evaluate whether flatbed UV inkjets have a place in your business, consider the following answers to questions frequently asked by screen printers about the technology:

Can I afford flatbed UV inkjet equipment? Flatbed UV ink-jet printers are less costly than multicolor inline screen-printing systems. Even so, highly automated, eight-color inkjet systems that cost in excess of a half million dollars can give some screen printers sticker shock. Fortunately, there are now comparable four- and six- color systems that provide exceptional output quality and productivity and start at under $200,000.

What is the learning curve? Those with good computer skills (i.e., proficient in using Microsoft Windows-based applications) can master basic ink-jet operating skills quickly. It typically takes the manufacturer a day to install a printer and start churning out good print quality. If the manufacturer is on site for a week of installation and training, the bulk of the time is available for instruction and applications assistance. The screen printer who plans wisely can leverage this time to get his staff up to speed on basic skills in the most frequently occurring applications.

Where can I find people with the right skill sets for operating ink-jet equipment? Most graphics screen shops already have talented employees in the art department whose familiarity with digital artwork and film-positive output quickly allows them to adapt to inkjet prepress and RIP operation. If you must look beyond your own company, look for individuals who have experience in prepress service bureaus and offset print shops. Anyone with a background in digital prepress can quickly benefit from the training opportunities provided by equip-ment manufacturers and other sources.

How difficult is it to integrate inkjet printing with my shop's workflow? Flatbed inkjet printing can be readily integrated with the workflow of any screen-printing shop. If prepress and RIPing occur in a separate location, you may decide to locate inkjet printing in that area. Or the equipment can be located right on the production floor. Flatbed UV inkjets are also ideal for stand-alone operations where a single operator does prepress operations, printing, and routine maintenance.

Is there anything flatbed UV inkjets can't print on? Sure, but it is not likely you would want to print on those things anyway. A prime example is plastic mesh. The ink sprays through the spaces and coats the printing equipment. Fabric, on the other hand, is very porous but inkjet works well on it, as well as on other relatively porous rigid materials, like wood. If you have in mind an extraordinary application that requires printing on a unique material, solicit the advice and assistance of the inkjet manufacturer.

Do UV inks give my prints better resistance to sunlight and weather conditions? No, this is a misconception. The term "UV curable" is sometimes confused with "UV resistant." Actually, both solvent-based and UV-curable inks provide excellent UV resistance and weatherability. In both cases, substrates generally deteriorate before the inks do.

What kind of support should I look for from the manufacturer? Some manufacturers do little more than deliver the equipment and provide manuals. Others have complete programs ranging from installation, training, and applications assistance to advanced training in RIP operation and color management. The best value is generally realized when you obtain comprehensive support along with the equipment.

Are flatbed UV inkjets as fast and efficient as claimed in literature from the manufacturers? You need to find out for yourself. The only print-speed data that count are certified by the manufacturer based on the level of quality you require using the substrates you will print on most frequently. Getting that number should be part of the demonstration process.

What is the secret to having a good demonstration? With just a little bit of preparation, you can have a great demonstration and find out everything you need to know about the flatbed UV inkjet printers you are considering. Here are a few tips:

• Make sure competing vendors use the same materials you will be using. This is particularly important if you are geographically separated. Materials readily available to the vendor may not be available in your location. You need to know that the inkjet system works well on your substrates.

• Take care in constructing your demonstration file. Forget about getting vendors to recreate a beautiful large-format color print that visitors will drool over. You can do your own later. A high-end inkjet is designed to do gorgeous process color, but will it do your bread and butter work? To find out, make sure your demonstration file includes large areas of flat color. Also include small text, knockout text, horizontal and vertical lines of different thickness against white, color, some images, gradients—everything you will run into all in one file.

• Be consistent. Once you have constructed (or obtained) a good demonstration file, print it on the devices you already own. Then have everybody you visit print the same file, so you can make a good, apples-to-apples comparison of printer capabilities.

• For more flatbed shopping tips, see –Figure 6.

A flatbed future

Rather than competing with screen printing, flatbed UV inkjet printing complements the process by enhancing a screen shop's productivity, expanding its profitability, and opening the business to new areas of opportunity. Neither the cost of entry-level flatbed printers, workflow-integration issues, nor training requirements should be barriers to entry for most progressive screen shops. Adopting this technology appears to be more of a question of when rather than if. But those shops that choose to implement the technology early will find themselves in a stronger competitive position.

Figure 6 Shopper's Checklist for Flatbed UV Inkjets

Use the following checklist when assessing any flatbed UV inkjet to determine whether that model is a good choice for your operation.

• Prints on substrates you plan to use

• Set-up time for printer and start-up time from image to image is efficient

• Offers flexible image quality to accommodate your customers' expectations

• Produces saleable image quality at the expected speeds

• UV inkset optimized for the widest range of substrates

• Prints the desired width

• Designed to minimize substrate waste

• Facilitates fast changeovers between various material widths and sizes, as well as rigid and flexible substrates

• Has tight integration with associated finishing equipment for user-friendly automation

• Built for reliable, non-stop operation

• Uses reliable printhead technology

• Manufacturer offers help transitioning to digital technology

About the author

Scott Schinlever is vice president and general manager of EFI's ink company, Inkware, Meredith, NH. Prior to joining VUTEk in 2001, Schinlever served as vice president of strategic marketing for Xerox Corp.'s Office Systems Multifunction division. He also has held marketing and general management positions in several small companies and ran a small graphics-software business. Schinlever holds an MBA from Duke University and a bachelor's degree in managerial economics from the University of California, Davis.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?