For screen-printing firms who are interested in exploring the potential of the vast, expanding market of wearable technology, industry consultant Ray Greenwood offers these tips:

For screen-printing firms who are interested in exploring the potential of the vast, expanding market of wearable technology, industry consultant Ray Greenwood offers these tips:

Keep expanding your horizons. Understand that the most important element of wearable electronics isn’t the “wearables” but the “electronics.” Electronics have rules and physics that can’t be faked. Wearable technology not only has to look good, but the products also have to work. Go to events and symposiums beyond the garment and printing industries to see what kinds of electronics are possible. Look for magazines, websites, and symposiums where the manufacturers of printed electronics (and the material and service industries that serve them) gather.

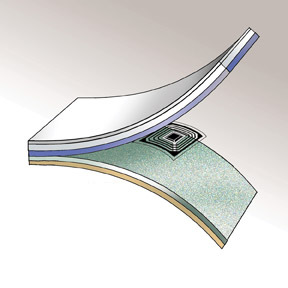

Learn the types of materials involved in making the types of electronic circuits and items that will be used to make garments with built-in electronics. Learn about conductive inks, films, adhesives, tapes, wire connector assemblies, weatherproofing materials, dielectrics, and cloth, plastic, and rubber substrates. Currently, a lot of testing is focused on discovering which types of cloth might be most practical with different electronic materials and circuit types.

Start an internal initiative to make samples and test the materials to understand what types of screen-making and -printing methods will be required. The product designers who come to you for proof of concept or prototyping will be looking for a printer who has at least some experience working with similar products, or at least with the types of materials in question. They will not come to you to start from zero.

Advertisement

Plan to maintain a very clean workspace if the manufacturing process requires anything more than laminating, heat sealing, or attaching an electronic device to a garment. For most wearables, you do not need a literal clean room, but you do need a clean space. For your own R&D, you can start by making a small quasi-clean room space with clean air, clean floors, and a separate screen-making area. You’ll also want to plan methods for documenting your research.

Invest in quality-control tools for screens and inks. And be diligent about writing repeatable processes for your screen-making and -printing setup. You cannot “wing it” with electronics.

Know what techniques are being explored on the path to making electronics wearable. It might be: direct printing of circuit on cloth; printing electronic heat, solvent, or adhesive transfers; laminating of cloth and plastic; or surface-mount devices.

Read more on the future of wearable technology or find resources across the industry.

Read more from our February/March 2016 issue.

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month ago

Case Studies1 month ago

Case Studies1 month ago

Andy MacDougall1 month ago

Andy MacDougall1 month ago

Editor's Note1 week ago

Editor's Note1 week ago

Columns2 weeks ago

Columns2 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Marshall Atkinson1 week ago

Marshall Atkinson1 week ago

News & Trends1 month ago

News & Trends1 month ago