The sacrifice of printing speed for high-resolution output often keeps graphics screen printers from shifting too much of their high-volume work to wide-format inkjet printers. Generally speaking, high-resolution inkjet printing requires a step-down in production pace because the printheads are required to precisely jet extremely fine ink droplets in order to deliver near-photographic or continuous-tone quality.

The sacrifice of printing speed for high-resolution output often keeps graphics screen printers from shifting too much of their high-volume work to wide-format inkjet printers. Generally speaking, high-resolution inkjet printing requires a step-down in production pace because the printheads are required to precisely jet extremely fine ink droplets in order to deliver near-photographic or continuous-tone quality.

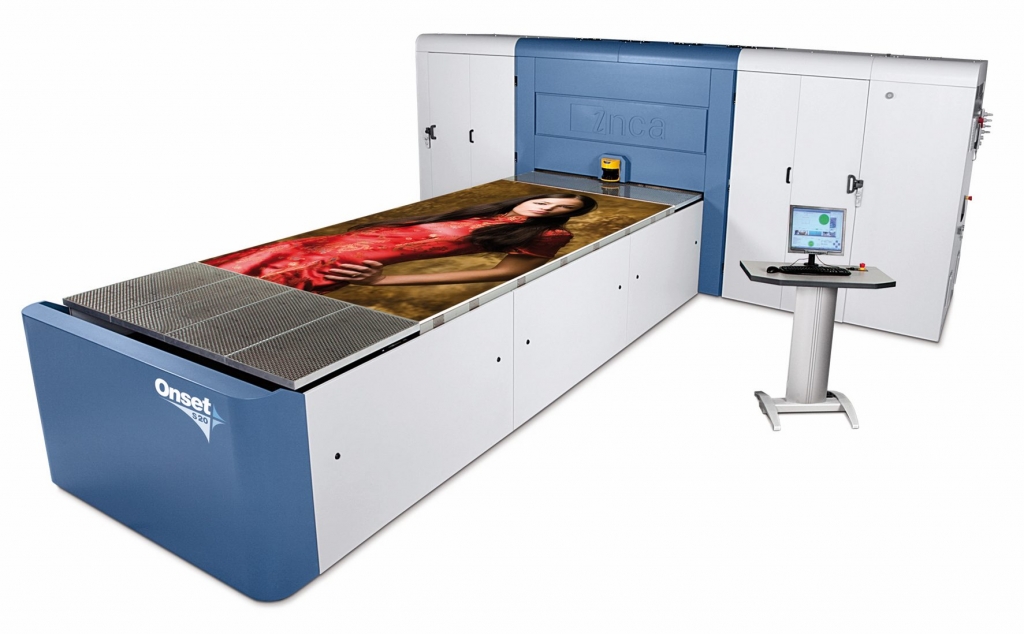

The Inca Onset S20 was designed to bridge the disparity between production pace and printing resolution while lowering the cost-per-print for high-volume graphics jobs. It uses a printhead array consisting of up to 156 Fujifilm Dimatix Spectra printheads that spans the entire width of the print bed and is designed to eliminate banding often associated with traditional step-and-repeat printing patterns. The Onset S20 delivers speeds up to 52 print beds/hr or 2690 sq ft/hr (250 sq m/hr) and resolutions up to 600 dpi. The device supports edge-to-edge printing in an area as large as 123 x 63 in. (3124 mm x 1600 mm) and accommodates substrates up to 2 in. (51 mm) thick.

The Onset S20 supports variable print finishes, from satin to gloss—controllable by the printer’s operator on a per-job basis—as well as 16- and 20-pass uni- and bi-directional print modes to take on applications such as indoor and outdoor signage, banners, P-O-P displays, backlit graphics, and exhibition materials on a wide variety of media. Dual registration points are designed to facilitate simple, precise media positioning for single- and double-sided printing. Other features include image-optimization scanning software to automatically balance color output for optimal graphic quality and automated software alignment that enables user replacement of printheads when service and maintenance are required. Media-handling options include a manual pre-load table, automatic take-off, and a ¾-automatic configuration.

Four- and six-color models are available, as is the option to print white ink. Users may add light cyan and light magenta or expand the gamut of the CMYK inkset by adding orange and violet Ultratone colors. White ink may be printed over or under four-color graphics in layers to manipulate opacity or used as a spot color. Both models use FUJIFILM Sericol Uvijet inks, which feature Micro-V dispersion technology to maximize pigment loading for exceptional color with minimum ink coverage. According to FUJIFILM Sericol, the inks are designed specifically to complement the Onset S20’s productivity and formulated for excellent adhesion, intense and vivid colors, superb dot reproduction, and low odor.

The Onset S20 comes standard with a dual-UV-lamp curing system that’s engineered for power efficiency and to provide consistent curing of ink in high-speed, bi-directional printing modes. RIP options for the Onset S20 include ColorGATE Production Server v5.3 or later and Wasatch SoftRIP v6.3 or higher. The printer offers connectivity via 1000 Base-T, operates on three-phase power at 150 amps and air delivered at 90 psi (6 bar), and requires a minimum floor space of 23.6 ft wide x 42.6 ft long (7.2 x 12.9 m).

For more information, contact FUJIFILM Sericol USA Inc., 1101 W. Cambridge Dr., Kansas City, KS 66103, 913-342-4060, fax: 913-342-4761, e-mail: sericolinc@fujifilmsericol.com, Web: www.fujifilmsericol.com.

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns3 weeks ago

Columns3 weeks ago

Editor's Note2 weeks ago

Editor's Note2 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks ago

News & Trends1 month ago

News & Trends1 month ago