Inks & Coatings

Published

18 years agoon

Among the characteristics that have made screen printing a popular decorating method, one of the most important is the durability of screen-printed inks. Both solvent and UV-curable screen inks have a reputation for delivering prints with vibrant colors that resist handling, abrasion, fading, and a host of other environmental factors. Combine these attributes with highly durable substrates, and the results are printed products that perform their functions for years.

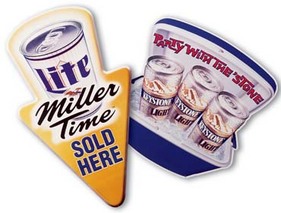

Among the characteristics that have made screen printing a popular decorating method, one of the most important is the durability of screen-printed inks. Both solvent and UV-curable screen inks have a reputation for delivering prints with vibrant colors that resist handling, abrasion, fading, and a host of other environmental factors. Combine these attributes with highly durable substrates, and the results are printed products that perform their functions for years. Some of the ultimate examples of high-performance screen-printed products are those that feature prints on metal substrates, such as steel and aluminum (examples of graphics printed on metal are pictured throughout this article). Metal signs, nameplates, appliance fascias and trim, containers, and many other products often rely on screen-printed inks to provide functionality in the form of graphics or markings. But producing such prints can be more than a little challenging for screen shops that are inexperienced at working with metal substrates. When it comes to printing on metallic materials, doing your home-work is a must. Knowing the nature of coatings typically found on metal substrates, the manufacturing tolerances of these materials, and the best ink/substrate combinations can mean the difference between success and failure. This article will review the main attributes of metal substrates that must be explored before a shop can work with these materials effectively. Additionally, the discussion will consider the ink formulations that are best suited for different types of metals and the performance parameters of images printed on metal. Understanding metal substrates In most cases, when we talk about printing on metal, the substrate is not raw metal. Rather, most metal screen-printing applications involve printing onto a coated or treated metal material. The coatings on metals tend to fall into two categories: thermoplastic or thermoset. A thermoplastic coating does not chemically react when the substrate undergoes drying after the coating process. The drying of thermoplastic coatings is accomplished by evaporation or by applying heat to fuse the material to the metal. The key thing to remember about metals with thermoplastic coatings is that the coatings typically are not resistant to high heat or aggressive solvents. In other words, the coating on the metal can re-melt with exposure to heat or strong solvents from the screen-printing process. A thermoset coating cures by a chemical reaction called polymerization and/or crosslinking. The coating is cured by baking the coated metals at high temperatures for long periods of time. Thermoset coatings tend to be resistant to heat and remelting, and they generally provide excellent solvent and scuff resistance. The resin systems used as base materials for metal coatings can be vinyls (either plastisol or solution systems), polyesters, or acrylics. Vinyl coatings are thermoplastic, and while they are much softer and easier for ink to adhere to than thermoset coatings, thermoplastic coatings have little chemical or abrasion resistance, which makes them unsuitable for most screen-printing applications. Thus, screen printers are more likely to deal with metal substrates featuring thermoset coatings. Polyester and acrylic are the most common resins used for thermoset coatings. Unlike softer thermoplastic coatings, which can be solvated by screen-printing ink, thermoset coatings have a harder crosslinked finish that can make ink adhesion difficult. When ordering coated-metal substrates from your supplier, make sure you ask what type of coating is on the metal (acrylic, polyester, etc.) and whether any slip agents or other surfactants have been added to the coating that may create ink-adherence issues. If surfactants are present, the supplier should be able to recommend cleaning agents that can be used to safely remove these contaminants prior to printing. Inks for metal printing Both solvent-based and UV inks are available for decorating coated metals, but solvent-based formulations are the most commonly used. While advances have been made that allow UV inks to perform well on a growing range of metal materials, the chemical properties and curing characteristics of UV inks still limit their functionality compared to solvent-based varieties. Solvent-based inks for metal printing fall into one of two categories based on whether they air dry (dry by evaporation) or heat cure (chemically harden or crosslink). Air-dried inks are normally vinyl-, acrylic-, or lacquer-based formulations. None of these inks experiences a chemical reaction during the drying process, and consequently, they are susceptible to scratching and scuffing, and they have poor or no resistance to solvents, gasoline, and/or aggressive cleaning solutions. The softer ink films they produce also can lead to blocking problems if they are not thoroughly dried. Because metal is a heavy substrate, blocking in the stack can create major problems. On the upside, most air-dried inks provide good flexibility and fair to good outdoor durability. Solvent-based inks that are set by heat curing rather than evaporative drying normally comprise some form of epoxy, enamel, polyester, or modified acrylic chemistry (epoxies tend to be the least suitable heat-curing inks for applications requiring extended outdoor durability). All these types of inks need to be cured at high temperatures, often for long periods of time. After curing, the printed ink film generally is very hard, and, as a result, more resistant than air-drying inks to solvents, gaso-line, and cleaning solutions, as well as to scratching and scuffing. These harder inks also tend to be less flexible than air-dried inks, but they may be suitable for heat embossing or forming. When properly cured and cooled before they are stacked, prints produced with heat-cured solvent inks normally do not block. UV-curable inks for metal decorating also come in two varieties: cationic or free-radical (acrylate). Cationic UV-curable inks have a chemistry that usually is based on epoxide resins. These ink systems are often slower curing than traditional free-radical systems, which are based on acrylated polymers such as polyesters or urethanes. Properly processed, both systems can provide good outdoor durability. Cationic and free-radical UV inks are chemically reactive and, when cured, produce hard ink films with properties of chemical resistance, scuff-resistance, and flexibility similar to heat-cured solvent-based inks. Matching inks and performance requirements Regardless of what ink type you decide to use for metal-decorating applications, the ink will have to satisfy the specific performance requirements of the job. For example, the ink film may need to provide a certain degree of hardness in order to resist scuffing, scratching, blocking, and solvents, yet be flexible enough to support bending, die cutting, and embossing. It’s unlikely that one ink and one type of metal substrate will fit all your production needs; instead, you’ll likely work with several varieties of coated metals and will need to match ink systems with each based not only on the specific coating, but also on the end use for which the product is intended. For example, if the product is for interior use, epoxies would be suitable, as would other resin-based heat-curing inks. If the product doesn’t need solvent resistance, an air-dried solvent-based ink may suffice. If the application requires a print that is both solvent resistant and durable outdoors, air-dried and epoxy-based solvent inks are not suitable, but other conventional heat- or UV-curable inks could be. Your top priority is to ensure that the ink film will adhere to the substrate after proper drying or curing, and depending on the material, some inks may not. To understand why ink selection is so critical for metal decorating, you must go back to the coating on the metal. If this coating is thermoplastic, many inks will adhere to it. But if the coating is thermoset (and, again, in most screen-printing applications, it is), printing with any type of screen ink becomes more difficult and the production process must be monitored more carefully and on a regular basis. The difficulty in working with metals that have thermoset coatings stems from the characteristic hardness of these coatings. The degree of hardness that a thermoset coating delivers is influenced by the type of resin system on which the coating is based, the way the coating is applied to the metal, and the way in which the coating is cured, which usually involves baking the metal after the coating process. The higher the temperature and the longer the duration of the curing process, the harder the surface becomes. And the harder the surface, the more difficult it becomes for any ink to adhere as required. A high level of surface hardness is the root of the problem that screen printers encounter in trying to get UV inks to adhere to coated metals. The shrinkage characteristics of UV inks, particularly free-radical varieties, are the main reason these inks have a difficult time adhering to hard, thermoset coatings. Depending on the formulation, a free-radical UV ink film may shrink substantially (up to 50% in some cases) as the ink rapidly crosslinks during the curing process. The ink film will cure and shrink in only seconds, while the metal substrate and its coating remain basically unchanged (Figure 1). Since the UV ink shrinks very rapidly, stress is placed on the adhesion point between ink and substrate. If the stress is great enough, the ink film can simply pop off the coated metal. In contrast, after a coated metal is printed with a conventional heat-cured solvent ink, the product must be baked at high temperatures for long periods of time in order to soften the surface of the metal coating to some degree and allow the ink to wet the surface better to achieve good adhesion. As the metal and coating cool, so does the ink film. Any shrinking that takes place occurs in slow stages allowing for good adhesion to be maintained. Cationic UV ink exhibits less shrinkage than the free-radical variety, but cationic formulations are often slower curing. Since less shrinkage is involved, these ink systems usually adhere better to thermoset-coated metals. However, cationic inks require higher amounts of energy to properly cure, and they continue to cure or post-cure after the initial UV-light exposure, which makes them more susceptible to blocking. When using these inks, you must take care to cure them completely to prevent adhesion problems. Another issue to keep in mind is that most commercially available coated metals are processed by a variety of coil-coating companies whose primary markets have nothing to do with the printing industry and more likely involve the commercial building industry or some other manufacturing market. Consequently, the metals they provide are often poorly suited for screen printing. The coatings can vary considerably in base chemistry and crosslink density, often limiting a UV ink’s ability to wet the surface. While one batch of metal may process well, the next could be too hard, exhibiting poor adhesion. To increase your chances of success in getting any ink to adhere to commercially available metals, the surface hardness should be confirmed and adhesion testing conducted (using the crosshatch and tape test) on each batch of substrate before the pieces are used in production. Additionally, dyne testing may be helpful in detecting any high levels of surfactants in the coating that could cause additional adhesion problems. The best results in printing on coated metal occur when you have some control over the coating process and can ensure that the coatings are cured to an appropriate hardness level. Work with your metal supplier and ink supplier to get coatings that are more receptive to your inks and continuously test incoming substrates to ensure they meet your standards. Several free-radical and cationic UV inks are being used today for a wide range of coated metal substrates. In each case, however, the metal supplier has worked with the printer and ink manufacturer to develop a softer coating that meets printing requirements. Most of these applications involve point-of-purchase applications, decorative signage, short-term displays, and indoor graphics. In general, heat-cured solvent inks (except epoxy-based formulations) printed on coated metal provide three- to five-year durability. Adding a protective clear coating can further enhance exterior performance. Prints produced with UV inks exhibit two- to three-year durability, but also can be used with clearcoats to extend exterior performance. Are you ready for metal printing? While plastics have become the dominant substrate for most graphics and signage applications today, the appeal of screen-printed metal substrates remains strong. The good news for screen printers who want to add metal decorating as a capability is that they no longer are limited to using only solvent-based inks. Thanks to improvements in raw materials, the range of UV-curable inks for metal printing has expanded substantially, bringing benefits such as highresolution, durability, and fast processing to the metal-decorating process. Regardless of whether you use UV formulations or solvent-based inks, if you work closely with your ink and substrate suppliers, learn to understand the materials they provide, and optimize your printing process to use these materials, you’ll achieve top-notch results on metal. About the authors Frank Blanco is vice president of distrib-utor sales in the US and Canada for Nazdar, Shawnee, KS. He has been involved in the screen-printing industry for 35 years. Blanco holds a bachelor’s degree in chemistry and a master’s degree in business administration. He is a frequent speaker at industry events and has contributed technical articles to numerous industry journals. Laura Maybaum is the product manager for point-of-purchase and metal-decorating inks with Nazdar. Involved in the industry for more than a decade, she has served in screen-printing technical and marketing positions with Nazdar, KIWO, and Sefar America. She holds a bachelor’s and a master’s degree from Bowling Green State University.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?