News & Trends

Innovation in Prepress

Published

6 years agoon

As we prepared our December 2017/January 2018 Innovation Issue, we asked members of the Academy of Screen and Digital Printing Technologies for their suggestions. Here, Mike Ruff discusses prepress innovation.

As we prepared our December 2017/January 2018 Innovation Issue, we asked members of the Academy of Screen and Digital Printing Technologies for their suggestions. Here, Mike Ruff discusses prepress innovation.

Nothing has seen more innovation in the graphics production industry than prepress. I define prepress as “work, functions, procedures, or processes that must be applied to a creation of artwork in order to transform a file to a printing plate or screen used by a printing press or digital printer prior to the action of press setup and printing.” Some would include plate making and screen making in this terminology. I’m not saying this is wrong, but for this article, I will just stop at the point the file is ready to be sent to a plate making unit, CTS system, or digital press. (That could be another article in itself if I went down the rabbit hole of adding plates or screens to the discussion.)

Also, I am not going to go back in time too far and bore you to death with firsthand knowledge about hand-cut stencils, cameras, real silk, and primitive screen making technology from those days, but let’s just start with the first major innovative tool that so quickly began to change everything in the graphic production world.

Desktop Publishing

Desktop publishing began to change everything in about 1985. When desktop publishing first became feasible, skilled analog prepress workers (artists, typesetters, and film strippers) scoffed at the quality of prepress coming from the newly established technology. Their claims that the quality was inferior were correct for the most part. The lower paid desktop computer operators lacked the skill and print experience of the old-time film strippers and the quality was not as good – but not for long. Quality quickly advanced in the modern prepress services. Professional prepress at that time required very expensive equipment for image manipulation and scanning, as well as highly skilled prepress technicians that most print shops could not afford. Because of this, all moderate-size metropolitan cities had “prepress houses” that supported local print shops as a way of reducing the investment of in-house prepress.

As computing power surged, so did the skill and knowledge in desktop publishing. Almost all the dedicated prepress houses disappeared. The ones that survived added services like digital proofing, screen making, and then digital printing. Now, most of these services are digital print houses or were acquired by print companies that wanted the knowledge base of their employees for their own prepress departments.

Accelerated Prepress Innovation Advancement

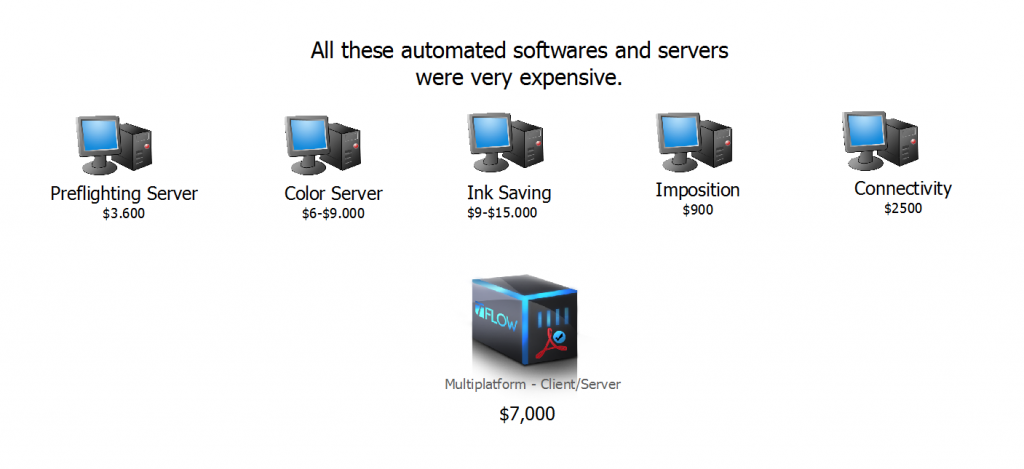

Software: In the ‘90s, QuarkXPress, Photoshop, Freehand, and Illustrator quickly established the modern prepress workflow that we see today. But most of the work was manual and slow. Shops with heavy workloads had to hire more and more people to keep up with the demand. Automation began to be a necessity rather than a luxury. Most of the early automation solutions were standalone. Compatibility was an issue at first but a problem that was rapidly solved. However, the software needed to do special functions and file work was clunky and could cost as much as $25,000 to truly automate. That problem went away through the introduction of software and servers that automated all these functions, or at least had plug-ins to do it.

Today, plug-ins and apps can do many functions automatically. Files can hit an automated server and actually be on a digital press within minutes, with no human involvement.

Color Management Innovation

With faster file preparation came the need for better, automated color management. It was not doing us a lot of good to get a file to press and have inaccurate color results. But where there is a great need, there are always great people who step up and solve the problems. At that time, the best technical people in the world worked for free on color management committees like the Print Properties Committee ISO/TC 130, CGATS, US TAG, GRACoL, SWOP, Fogra, G7, and others. These committees comprising prepress giants of the industry tackled these problems and solved most of them. They have provided the understanding of how color can now be precisely controlled for proofing and plate/screen making prior to a file reaching the press. This was huge in increasing profits for print companies that were innovative enough to invest in cutting-edge prepress technology.

What most people were seeing, but not really paying attention to, was how fast software innovation was changing. The speed and processing power of the software was not supported by the graphic computers at first. Now, low-cost computing systems handle most of the very sophisticated software in prepress. In fact, many professional graphic producers process files on their laptops.

AdvertisementBy the mid-2000s, prepress was evolving even faster as traditional print companies were attempting to survive the disruptive digital revolution. Again, prepress software and equipment companies embraced prepress innovation, integrating it into their products. Most of the time, it was so well camouflaged that printers didn’t know why it worked so well – they just knew it did. Great prepress was now possible by marginally skilled technicians.

The Printing Equipment Trap

In the analog equipment era, a company in the graphics industry could buy a piece of equipment and it was useful and competitive for 20 years. With the advent of digital, many companies were getting caught in the trap of buying very expensive digital equipment that would be close to obsolete in five years or less. Not understanding this sunk a lot of companies. Digital equipment that was “state of the art” could quickly become a cash-sucking boat anchor with a huge maintenance contract. Our industry had never experienced that before and some did not survive.

Today’s Innovation Opportunities

Today, prepress departments are smaller but much more technical. This is driven by a workforce of incredibly talented millennials who do not remember when laptops didn’t exist and are superhuman in their understanding and use of technology. They learn quickly because digital is just part of their lives. Sophisticated software does not intimidate them and they are now producing up to 10 times more files than their Gen X counterparts did. I love to watch them work and I look forward to seeing what innovation they will add to our fast-changing industry.

What Will the Prepress Department of the Future Look Like?

Automation has already advanced to very high level in prepress thanks to companies like Fuji, Esko, EnFocus, EFI, Canon, Chromix, Xerox, Sony, 3M, Agfa, Tucanna, and many others, but new systems are now coming to market that enable prepress technology to move to a level not seen before.

Is this disruptive? I do not believe prepress technology actually qualifies as a disruptive force because it represents pure innovation that makes products more affordable and accessible to a wider range of print customers. It is advancing our industry, not destroying it. I see three areas that I believe will separate the “innovative” prepress shops from the “wannabes.”

1. Cutting-edge color management. Productivity with no production-stopping color control issues.

Advertisement2. Truly automated, one or two person workflows even for large print shops. The prepress technician of the future will not be doing anything but supervising software, updating and innovating a system that does the work for them.

3. Prepress taking control of estimating, purchasing, and costing. Handling files will be too simple for the prepress technician of the future. The estimating, purchasing, and costing workflows will be integrated into prepress workflows in the future. In fact, it’s happening now.

In Conclusion

Prepress innovation is allowing us to be profitable in a technical, screaming-fast world that would destroy us without the tools and software now available to us. Thank you to all the prepress innovators that have provided these products. But I close with a warning: We need to abandon our personnel hiring thinking of the past. A wrong hiring approach will delay or completely stop the evolution toward a totally automated prepress print shop. The number one mistake is to think we need to hire traditional prepress personnel with massive print experience. We must think differently. The people we need in these highly technical positions are younger, like the top IT grads from Cal Poly, RIT, Clemson, and MIT. We need fearless software and computer geeks with IT experience. These are the employees that will drive our companies forward by reducing cost, increasing quality, doubling speeds, and differentiating us from the competition. Happy hunting!

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

Livin’ the High Life

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Editor's Note1 week ago

Editor's Note1 week agoLivin’ the High Life

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson1 week ago

Marshall Atkinson1 week agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Press Releases2 months ago

Press Releases2 months agoBig Frog Custom T-Shirts & More of Round Rock Celebrates Grand Opening