Tips and How-To

Profit Potential in Digital Decorating

How to use digital methods to bolster your business.

Published

5 years agoon

I’VE BEEN A PROPONENT OF digital decorating since the early 2000s, when I was involved with some of the original commercially viable direct-to-garment printers. Later, I fell in love with other embellishment methods such as sublimation, vinyl, and bling. That doesn’t mean I’m a detractor of conventional screen printing; I love the art of screen making and the passion artists have for the craft. I have long believed the people in our industry aren’t screen printers, sublimators, or heat-transfer specialists, but instead are garment decorators.

Successful business owners understand their job is not only to print, but also to provide their customers with an end product that makes them feel unique, serves as a walking billboard, and is something they’re proud of. To help customers achieve these goals, it’s important to have a good understanding of the different ways a piece of fabric can be decorated, even if it isn’t a technique you plan to use in your production facility. You may find utilizing digital methods of decorating can be an excellent complement to an existing analog print shop looking to expand its offerings. How can your shop break into digital without overextending your business?

Three Digital Decorating Techniques: A Primer

1. Direct to Garment

Direct to Garment (DTG) printing most closely resembles traditional screen printing. The process at a basic level involves loading a shirt onto a platen that indexes underneath an inkjet printhead using special ink that will bond to the fabric once cured with heat. On light fabric and garments, the process uses CMYK 4-color ink. For dark fabric, or any white in the design that isn’t created by the white of the garment, the process requires pretreatment of the substrate. Many users buy pretreatment application devices; alternatively, blank garments pretreated during manufacturing are becoming more readily available. The pretreatment is a sodium-based solution that begins the curing of the white ink. The white ink contains titanium dioxide, which starts to cure when it comes in contact with the pretreatment, allowing the CMYK inks to be printed on top of the white, instead of the white ink just falling into the shirt. It’s a bit like the concept of flash curing an underbase in the screen-printing process.

DTG is great for short-run, full-color printing onto cotton. Manufacturers are working on pretreatments for polyester and some products on the market now, but cotton still seems to be the go-to for DTG. The benefit of this printing method is a nice, soft hand and the ability to print one to 16 million colors with no setup – just put the art in the computer and push print. It’s not an economical technology to employ for long runs or low- to mid-range production of one- or two-color work when compared to screen printing. Some decorators are now using DTG to add personalization to screen-printed shirts or to create contrasting texture between the thicker plastisol inks of screen printing and the soft hand of DTG.

2. Sublimation

Dye sublimation is used with polyester fabrics. The process takes a special sublimation ink and transfers it to a polyester or polyester-coated surface with the use of even heat and pressure through the chemical transformation of sublimation. The pigments in the sublimation ink convert from a solid to a gas at different temperatures. When heated, the pores in polyester open and the heat transfers the pigments into the polyester, permanently bonding the color into the fabric. The pigments are translucent, so any existing color in the polyester will change to the color of the pigment. White inks and underbases aren’t possible with this process, therefore most sublimation transfers are done on blanks that start white and the entire surface is decorated to change the background color when needed.

Dye sub imprints are not only permanent and withstand as many washings as the garment can handle, but the colors are also bright and vibrant. Another advantage to sublimation is that you can’t feel the ink on the garments because the ink becomes part of the polyester. They breathe well and can be sold as an athletic advantage due to the moisture-wicking property of the fabric. Polyester’s popularity as a garment choice continues to grow as the feel of the fabric continues to improve – gone are the scratchy polyester leisure suits of the ’70s. Companies like Under Armour and other athletic-apparel brands popularized polyester garments for sports teams and have now become a mainstream product. As with DTG, there’s a lot of mixed media, plus more and more companies are investing in the ability to cut and sew their own garments to eliminate the “smiles” (unavoidable blemishes under the arms and around the seams) when sublimating on a pre-constructed garment.

3. Heat Printing

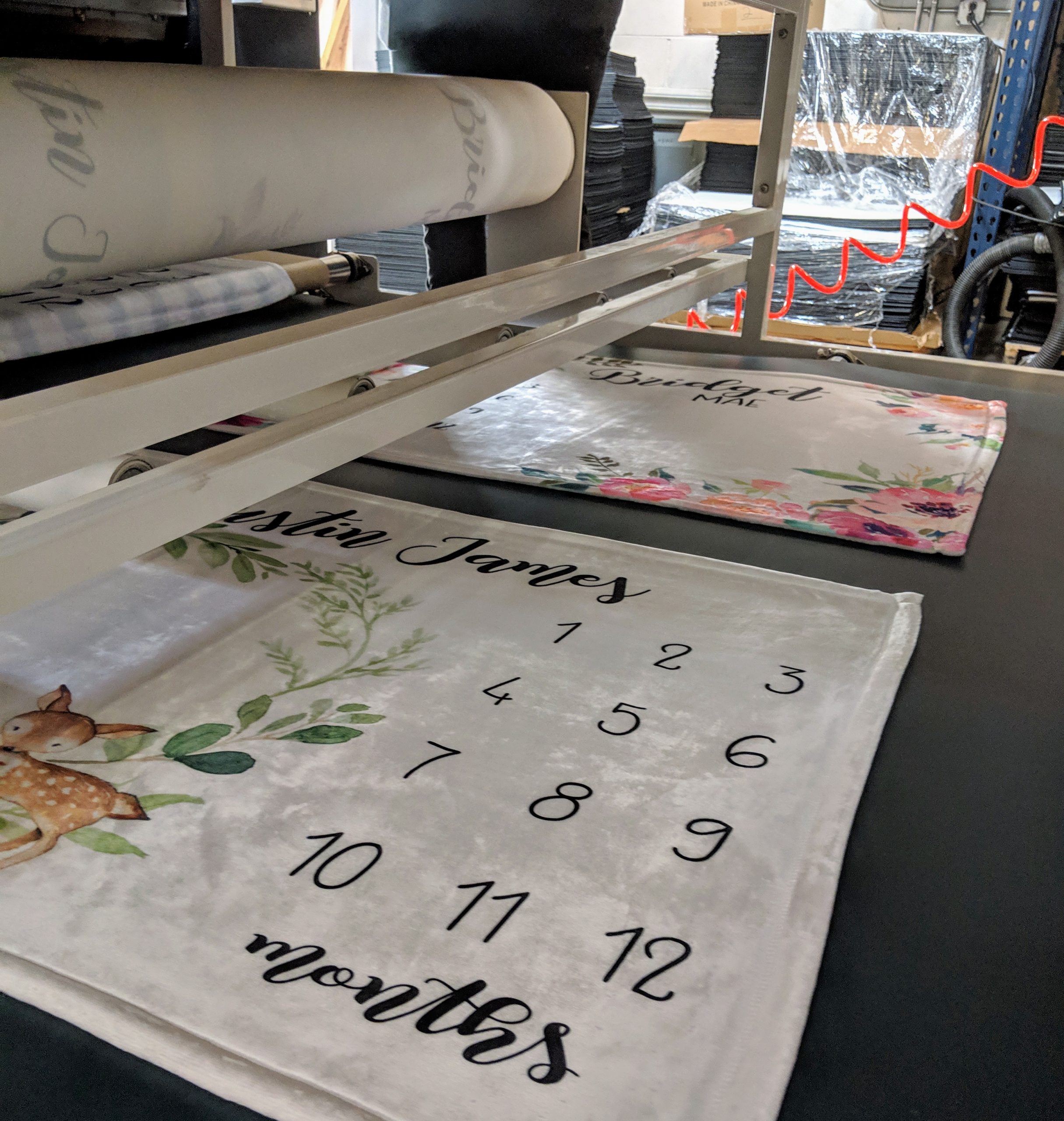

Heat printing actually encompasses multiple areas and is a bit of a catch-all. This includes print-and-cut vinyl, cut heat-transfer vinyl, digital transfers like inkjet and laser, and other embellishments like rhinestones. The prepress process is similar to DTG and dye sublimation: you design the item to the customer’s specifications in your graphics program and send it to a printer or cutter with no need for any set-up or other steps. Once printed, you use a heat press following the transfer manufacturer’s specification for the time, temperature, and pressure to be used, and apply the transfer to the substrate. The heat process bonds glue, for lack of a better term, to the garment and you have a commercially viable item you can sell to your customers.

When paired with a commercial-level heat press, these embellishments can withstand a reasonable amount of washing and produce some brilliant results with the fun flash of rhinestone, sparkle of glitter, and stretch of vinyl. Some of the products do have a heavy feel to them due to the thickness of the vinyl or transfer, which can be clunky if the graphics are large. But for decal items where a lot of the shirt comes through or for smaller graphics like left chest logos, this can be the perfect way to decorate a small order of garments. I recently got three new polo shirts made for my consulting company from a printer with a print-and-cut vinyl setup and love them!

Easy Access

All of these techniques are growing in the marketplace because they are digital. You can make a unique item for your customer and your costs don’t really change much as you scale. Plus, people are willing to pay a premium for something that is made exclusively for them.

With heat printing, you have a wave of crafters with inexpensive Cricut or Silhouette cutting machines making shirts for their friends and neighbors. Suddenly, they have created a little business because of the demand for personalized items – and they are now your competitors with little to no overhead (and no idea how to price the products).

With dye sublimation, you can have pretty much everything you need to make small-format items for around $500. With DTG, options range from massive $250,000 printers that can crank out shirts, all the way down to inexpensive kits to convert an off-the-shelf printer into a DTG machine. Because of this accessibility to equipment, it’s important to understand the options when it comes to digital decorating. The demand for personalized items is high and you may not even be aware your customers are going elsewhere for these products. So how do you swallow all of this without putting your business in debt for a market you are still learning about?

To Outsource or Not to Outsource

I have been on both sides of the aisle in my career in this industry. I was involved in DTG back in 2004 as the VP of sales and marketing for one of the first DTG manufacturing companies. DTG was the shiny new toy our customers wanted to try, but I saw so many businesses fail because they invested in the technology and then realized they had no market for it. The equipment sat unmaintained because they had no money to put into it, and then a big job would suddenly pop up and they couldn’t get it done.

You need to introduce these digital decorating tools into your business with a market already built – it’s a completely different animal from the traditional printing methods. At the company where I worked 15 years ago, we actually tried to talk some people out of buying the tool because they were ill-prepared to utilize it. Today, however, it’s a whole new world of DTG with far fewer minefields to navigate. The equipment has improved immensely and there are several wholesalers you can work with to build your market before investing too heavily in digital decorating.

So, how do you outsource with a wholesale provider? First, make sure you can trust them. What does your gut tell you? You will be using these companies as an extension of your business, so you have to trust they have your best interest in mind. Most of these companies know the more success you have, the more success they have. But some are starving for business – and they will make any promise they can to get you in the door. A good rule of thumb: if it sounds too good to be true, it probably is. Look for a company that speaks realistically about what they can accomplish for you, as opposed to selling you the best case scenario and falling on their face more often than not. Also, try to clarify how they handle any mistakes that occur or when something is lost in transit. Do they look at you as a partner or as a dollar sign?

With outsourcing, you have to change your thinking a bit. Will you make as much money as if you had the equipment yourself? Probably not from a straight cost to cost analysis. But, what other costs are you forgetting to factor in? Consider the time to get up and running, the pain your customers might experience as you tackle the learning curve, the spoiled products in production, and inventory carrying cost. When you outsource to build your market for personalized products, you don’t have to worry about any of those things and you can let the wholesaler teach you the nuances of the decorating techniques before you bring them in-house. Something else to think about: what is the cost of spending your time in production when you could be out selling, marketing, and growing your income? I have witnessed shops that go all in on the equipment, hustle to try and make the production work, and then end up seeing their business take a dip because they were focused solely on how to complete orders and not on filling the sales pipeline. There are “costs” to those things, even though they might not show up on a profit and loss statement right away.

Glimpse into the Future

The demand for customization is only going to grow and it could even drastically change how we buy our clothing and other daily use items like phones, mugs, headwear, and more. This will continue to impact our industry because it’s going to change the humble T-shirt. Charles Ohiaeri, chief fulfillment officer of e-commerce company Zazzle, says 67 percent of their orders are personalized and their network makes 250,000 products a day. Customers are encouraged to envision a product they want, create it through the Zazzle platform, and it’s in their hands within 48 hours. How does this change your business? Your customer comes to you and says, “Zazzle will make me a shirt from scratch in 48 hours. Why can’t you make just one today because I’m standing in your shop?”

The world of apparel is already seeing major disruption from “fast fashion” – a quick manufacturing turnaround from catwalk to stores, allowing consumers to inexpensively purchase the latest trends at retailers like H&M and Zara. Some consumers are taking it a step further with customization. Whimsy Rose, a local company in St. Louis, is pushing the envelope with their sublimation equipment by allowing their customers to walk into a store, try on white blanks to pick the proper fit and feel, then head to a kiosk and design their own look and style. The customer places the order and then they can have it shipped directly to their home or they can return to pick it up in a few days. Whimsy Rose is launching this program with several major distributors around the world so those distributors don’t have to inventory a bunch of stuff they hope will sell. Instead, they only need to have a set or two of the blank products, some finished goods to show the print quality, and they have instant success and no inventory risk.

I also think we will see clothing sizing change. There will no longer be a size medium, but instead an “Aaron-sized” garment based on a digital scan that might even come from our smartphones. Digital one-pass printing technology is evolving quickly, so the ability and cost to customize will continue to change to the benefit of the consumers. Decorators need to start thinking about how they can help their customers set themselves apart through customization and personalization of products. Recently, YouTube announced a partnership with Teespring to give their content creators an avenue to sell shirts to their viewers. Those are thousands of “brands” that need a tangible product their viewers can connect with, because we are human. Until we all become cyborgs, we have a tactile need to connect so there’s a lot of business to be had out there.

PHOTO GALLERY (8 IMAGES)

Aaron Montgomery, president and CEO of MontCo Consulting, has worked in the garment decorating world for almost 20 years. He is actively involved in the industry as a speaker and writer on such topics as marketing, social media, the personalization market, sublimation, and garment decorating techniques. As a consultant, he assists small businesses through planning and setting up their company with a customer-first mindset to give them the best chance to succeed. He co-hosts an industry podcast 2 Regular Guys Podcast and has his own podcast channel on his website as a replay of his weekly Small Business Saturdays Series. New episodes are released weekly.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

Livin’ the High Life

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Latest Feeds

Advertisement

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?