Garment Printing

Published

13 years agoon

Even the most experienced screen printers cringe when clients decide to throw different garment types into an existing order. The situation brings up all kinds of questions: Will the ink adhere to each fabric? Can we use the same artwork and separations? Do we need to change press settings? All of these questions are appropriate to ask, because printers often to push through these types of challenges without a lot of extra client interaction in hopes of avoiding the impression that they are difficult to deal with or that they can’t handle a complex job.

Even the most experienced screen printers cringe when clients decide to throw different garment types into an existing order. The situation brings up all kinds of questions: Will the ink adhere to each fabric? Can we use the same artwork and separations? Do we need to change press settings? All of these questions are appropriate to ask, because printers often to push through these types of challenges without a lot of extra client interaction in hopes of avoiding the impression that they are difficult to deal with or that they can’t handle a complex job. Still, it is crucial that printers address the variables inherent to working with different types of garments before running the job

The best way to avoid any issues is to first be aware of garment-fabric qualities and print limitations, then review the artwork to determine whether it will present any challenges when printed on particular fabrics. Finally, it is wise to look at the production workflow and check for problems with printing methods, inks, or press settings.

In the best case scenario, the job will run smoothly all the way and the extra garment style will just flow right through with the rest of the order. But there are times when real challenges come with adding a different fabric into the equation. Experienced printers can often shoot from the hip and know what trouble they may encounter with different garment types, but it still pays to do a quick checklist and walk through each question that this scenario brings up.

T-shirts

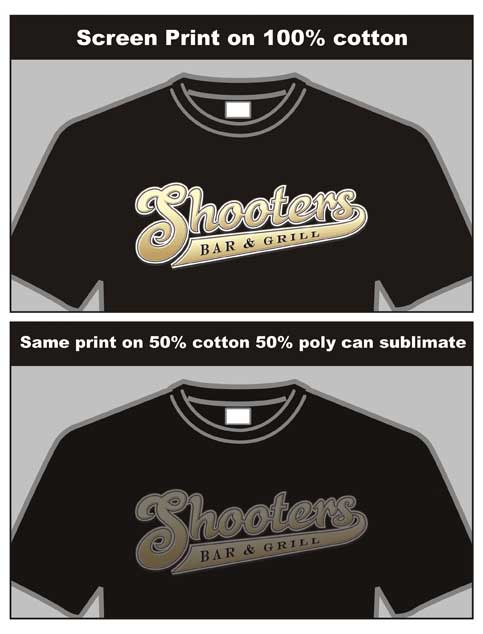

If the garment addition is another type of T-shirt, the odds are high that it will be OK and the print will run well as long as the fabric type of the T-shirt is the same as the one in the original order. If the original shirt order is 100% cotton, the additions are a dark color, and they are 50% polyester, then it is possible that an art issue may be involved or the garment dye may sublimate into the screen-printing ink (Figure 1). In this case, the artwork should be reviewed and the inks potentially changed to a different formula (non-bleed).

Hoodies

In the majority of cases, the art and print that works on a T-shirt will also print effectively on a sweatshirt or hoodie. Exceptions to this are similar to those related to the T-shirt with colors and cotton content. An additional concern with adding a hooded sweatshirt is often a smaller printing area on the front with the pocket and the hood itself potentially covering over the print on the back of the garment. A final concern with printing the same art on a hoodie that is part of a T-shirt run is that the hoodie can push up into the screen due to the increased thickness of the fabric and cause the print to smear and bleed more. This issue is typically dealt with by increasing the off-contact on press but complex artwork with a lot of halftone dots sometimes requires a lower resolution, a change in ink volume, more squeegee pressure, or a different squeegee angle to adjust for thicker fabric.

Polo shirts

The majority of printing issues are related to pique polos with a coarse weave in the fabric. Some printers like to print these garments; many simply won’t print them at all. The client can usually be steered away from attempting a complex print on a pique fabric. If they do insist on it, they should be warned that it will probably look very rough and that small details will be lost. Other concerns with jersey-style polo fabrics are similar to the T-shirt issues. A specific concern with polo shirts is the placket and buttons on the front of the garment. Occasionally, clients will want to print across seams and print onto these areas. Custom platens are often required to do this type of work, and printers should inform their clients that it is rare for this type of print to work in the same run as a regular T-shirt (Figure 2).

Performance fabrics

Performance fabrics include a wide variety materials that are lumped together under this heading for convenience.

The important issue is whether they are polyester and are heat sensitive. Dry-wicking mesh garments that are mostly polyester weave with some lycra in them are common in this category. These garments can be very printable, but printers must exercise caution in regard to heat, particularly when the print is a complex one, either in detail or number of colors.

All poly garments present a challenge when it comes to holding shape over a multicolor print, and they can also be difficult to work with when flashing is needed because the fabric likes to expand and contract. A loose mesh garment, like pique polo, isn’t the best choice for highly detailed prints, and a garment engineered with a lot of Lycra may not be able to go through the dryer without melting (some compression garments are better heat pressed than printed). A good rule is to acquire a sample prior to guaranteeing a quality print, test for heat sensitivity, and review the fabric’s surface for print and art concerns.

Miscellaneous garments

I have seen more than a few printers get hung up when printing a shirt order and then trying to run the same design on just a few draw-string bags, only to find out that the bags are made of purple nylon. Nylon is very tricky to print and requires a hold-down frame to prevent it from peeling off of the platen. In addition, a special resin has to be added to the ink to produce a durable, washfast print. Nylon fabric is an extra challenge, regardless of which type of apparel is made of the material. The best bet on just a few items is to really simplify the art and produce a separate print (Figure 3).

Other garments worth mentioning are a tricot style warm-up jacket and some of the eco-friendly fabrics, such as hemp or bamboo. These all can print very well, but printers must take extra caution and acquire and test samples to guarantee they will remain washfast and not melt, shrink, or burn. Additional concerns to consider whenever an item is not a T-shirt is fitting it onto the press and working around straps, zippers, seams, or other areas that can cause a problem.

Will the same artwork and separations work on different fabrics?

As many times as this question is asked, the answer ends up sounding similar: It depends on the art and the fabric. The common sense approach is a good place to start. If the fabric is rough, the artwork should be rough or less critical in location, style, or composition. This also applies when the artwork is printed over a seam or off of the edge of the garment. Fabric that is all polyester tends to print satisfactorily, but it may bleed upon exposure to excess heat. Printers should consider simplifying the artwork in number of colors so flashing is not required. Separations should work with similar fabrics as long as the garments have the same background value (separations that are made for a dark background may not work on a light one) and as long as the cotton content doesn’t vary too much (this may require a stronger underbase depending on the sublimation of the shirt dye through the top colors).

The biggest concern for a separator when different fabrics are thrown into the equation is what type of effect—if any—different surfaces will have on the color combinations on press. A pleasant surprise is possible from time to time, but it is always better to know beforehand. Get a sample, and test it before agreeing to print. Knowing in advance that artwork will be printed on a variety of fabrics gives printers a chance to look at each type of fabric and try to find a middle ground that will work on everything or bite the bullet, call the client, and offer some workaround to do a separate process. It is far smarter to force the issue beforehand and persuade the client to accept a different print type or process than to attempt it and fail with expensive items on press.

Garments such as performance fabrics, specialty bags, and golf shirts end up a clear question of value vs. liability. What this means is that a printer always has to consider the value of the item—and its potential replacement should the print fail—in relation to the amount they earn in the printing process. It is not a good to put a $1.50 print on a $150.00 Nike jacket. There is just too much liability in it vs. the gain the printer gets out of it. One of the reasons that heat pressing and embroidery are better options is that there is less likelihood of scrap.

Price drops confuse print shops

The practice of clients going on last-minute shopping trips and then trying to add the items they pick up to their order is becoming increasingly common. Many retailers often slash prices to the point that the garments a client can sometimes get are priced far lower than the blanks the printer provides. Then the discussion becomes one that’s focused on how no one knows whether the garment will print as expected and how the printed graphics or garment fabrics may change as they travel through the dryer. The growing number of strange garments that are brought in to be decorated means printers must inform their clients that supplied garment might not be receptive to printing and that no guarantee can be given on customer-supplied.

Printing on a wide variety of fabrics is more popular than ever, and it is likely that customers will continue to complicate there orders for the foreseeable future. To stay ahead of the curve, a printer needs to be proactive with sampling and testing and keep clear records of what worked and what didn’t to prepare for the next time a couple of bags are thrown in to an otherwise simple garment job.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Editor's Note1 week ago

Editor's Note1 week agoLivin’ the High Life

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson1 week ago

Marshall Atkinson1 week agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?