Trends

Special Effects: Taking Your Shop to the Next Level

There’s now a premium on dimensionality, with effects that literally rise out of the traditional flat print.

Published

6 years agoon

AS MANY SUCCESSFUL print shop owners have learned, adding the hottest special effects to your product offerings allows you to add sizzle to your sales. We all strive to set ourselves apart from ordinary apparel decorators, and that’s why we reach into our bag of special-effect tricks. Plus, screen printers have resources and tools at their disposal that decorators using other processes don’t, enabling them to add that extra something that can win the order.

Special effects also play nicely into fashion trends, as they have for some time. Most of us remember brands like Ocean Pacific (OP) from the ‘80s. We weren’t the only ones wearing surf shorts and very cool corduroy shorts. Many of today’s styles are still rooted in surfing and skateboarding as fashion has morphed into a hybrid drawn from many cultural influences – extreme sports, urban landscape, music, and ultimate fighting, among others. No matter where you shop, special effects are everywhere, breaking all the rules of design, printing, and applications.

This revolution in decorating techniques has steadily increased the perceived value of the shirt and placed a premium on dimensionality, with effects that literally rise out of the traditional flat print. Today’s printers have tool boxes packed with multiple decoration processes that can be combined to give garments unparalleled visual and tactile appeal. Though it may seem at first glance that the garment market has few truly new special effects, the reality is that inks, fabrics, and printing processes are constantly evolving in response to consumer demand. The slow but steady trend toward PVC-free inks and the popularity of performance fabrics are just two examples that have driven innovation in our processes that, in turn, give you the ability to continually show customers embellishment choices that are truly new and different.

These developments give screen printers a unique opportunity to look beyond special effects and redefine themselves as specialty printers. I frequently present seminars and workshops at trade shows and other industry events, as you may know, and over time my topics have changed from special effects to specialty printing. It may sound like semantics, but what I’ve learned in my business is that it’s the difference between selling a process and creating value. Specialty printing means turning an ordinary print into something special. Great art combined with effects creates products your customers will be willing to pay for, increasing your margins.

There has always been a certain air of mystery in the industry about special effects. Much of what I try to teach (or sell, as the case may be) is taking the perceived complexity out of this work. The reality is that printers with a reasonable grasp of the basics can tackle many specialty printing applications. The fundamentals of screen printing are the foundation. Even advanced techniques are all about doing the basics really well. Sure, a number of techniques are difficult and only the very best printers tackle them, but other popular processes are fairly simple and can be printed using basic materials.

Thirty years ago, most printers might have only been able to offer puff, metallic, or basic water-based prints. Today’s equipment and materials are far superior, with countless specialty inks, meshes, and stencil systems that require only the mastery of basic techniques. But it’s your responsibility to push past what these products were designed for, keeping in mind the qualities that attract your customers – things like texture, dimension, touch, and feel.

Advertisement

Explore just some of the ways specialty printing can make your shop stand out.

A World of Possibilities

Special-effect techniques are continually being reinvented with a new spin to keep pace with fashion. Texture, for example, goes in and out of style – or the lack of texture in the case of discharge and burnout printing (in which cotton is chemically removed in a post washing). Both looks happen to be popular right now. Products like high-density (HD) ink, multiple types of gels and clears, and even the familiar puff inks all add interesting textures. “Sugar” and glitter inks are in demand. Combine these options and you can get some amazingly realistic effects. In my shop, we like to say, “If we can make it look and feel like something it ain’t, it always works.” Classic suede and leather as well as cracked ink treatments mimicking the texture of rocks, sand, or even animal skin all make the customer want to touch and feel the embellishment.

Then, of course, we have customers who don’t want to feel any texture at all, the reason that water-based inks on light garments and discharge printing on darks remain popular. The techniques and inks have been reinvented over and over. Some high-solids acrylic (HSA) or opaque water-based inks can work well on cotton, most polyester, and blends. These inks are commonly used with blockers on polyester fabrics to minimize the potential for dye migration and bleeding. HSA and hybrid polyurethane versions allow us to print water-based ink through higher mesh counts and achieve a superior level of detail. We can even use these and discharge inks thinned in spray bottles or electric sprayers for garment treatments, or combine them with textured inks and add some sequins, rhinestones, nail heads, or even foil for a very hip presentation. The combinations are endless.

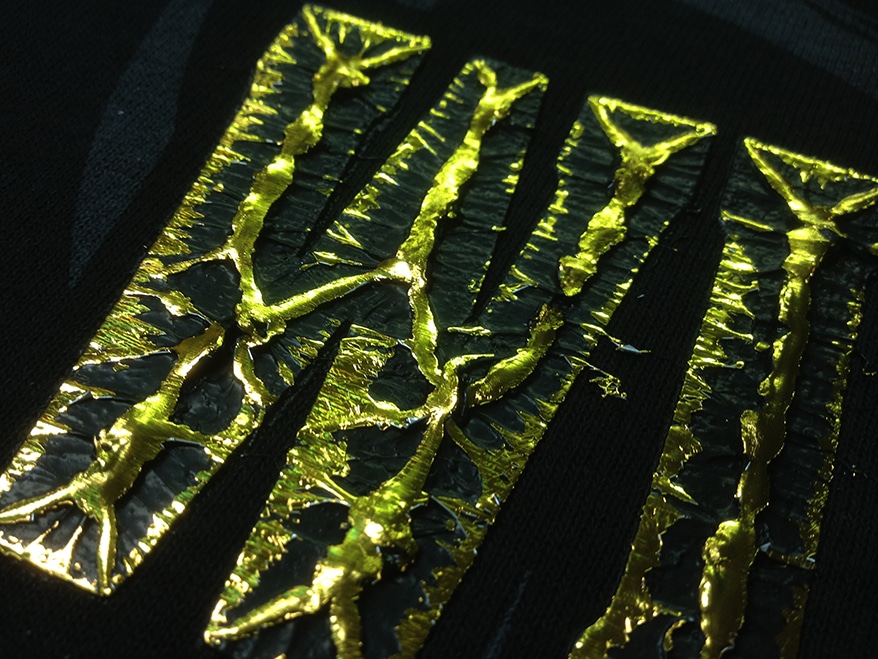

A black base topped with multiple distressed foil applications overprinted with an HD clear.

Recently, we’ve been working with the latest wet-on-wet water-based ink technology. This is a very exciting development because HSA inks typically require many more flashes and print stations. We’ve used wet-on-wet inks to produce four-color process and simulated process separations with five to ten colors, printed wet on wet with minimal flashing.

Other non-PVC solutions include “acrysols,” inks that behave much like a plastisol on press. A variety of textures are available in this category. Silicone inks, which are also PVC free, allow for some great applications, particularly on polyester compression fabrics because of their low curing temperatures and elastic characteristics. We use thickeners to stack some nice HD effects, and the gels are truly clear and ultra shiny. We’ve used them to develop some great doming effects.

AdvertisementSome techniques such as reflective and glow-in-the-dark inks have reemerged better than ever over the last few years. You don’t have to live with that nasty green glow or dingy gray reflective any more. Photo-chromatic and thermo-chromatic inks that respond to light or temperature have come back around as well. Remember scratch and sniff? Think of a Hershey’s Kiss logo that smells like chocolate. Countless such scents are available today.

As we know, colored metallics, shimmers, and glitters have been around for a while and can be executed in any number of ways. Using a receding base that fades into the garment during the curing process, we’re able to get a hand-sprinkled appearance that leaves the glitter on the surface. We sometimes suspend a low percentage of the flakes into a clear and overprint that onto other colors. Ink manufacturers have taken silver and gold to a new level with products that look like liquid precious metals, more convincing and durable than ever.

As we know, colored metallics, shimmers, and glitters have been around for a while and can be executed in any number of ways. Using a receding base that fades into the garment during the curing process, we’re able to get a hand-sprinkled appearance that leaves the glitter on the surface. We sometimes suspend a low percentage of the flakes into a clear and overprint that onto other colors. Ink manufacturers have taken silver and gold to a new level with products that look like liquid precious metals, more convincing and durable than ever.

Flock, foil, and other inline transfer applications remain popular in some fashion brands. While the equipment can be expensive, these applications can also be overprinted to achieve a variety of new effects.

Good Artwork Is Key

Remember, it’s a “garbage in, garbage out” business. Every successful garment embellishment begins with the art. The designer must become familiar with the processes and should also have a grasp of their variables and limitations. Taking these into consideration at the design stage will result in artwork that is finely tuned to each technique’s characteristics and capabilities. This makes the final print more precise and easier to run in production.

When we’re planning for a specialty application, we try to design the special effects as fairly basic elements within the image. Shadows or highlights are a good place to start. We avoid fine detail and identify any limitations that may be imposed by the application. We keep in mind that the inks may move or change shape. For example, we know puff grows in multiple directions in the dryer, so we allow space for this to avoid smearing. Using chokes, spreads, gutters, and traps can be a big part of successfully executing many of these effects on press. A skilled designer and separator will create room for special effects in the print sequence as well by using fewer heads to achieve the desired result.

The cat’s fur was printed with puff ink; the eye was done with simulated process overprinted with a clear gloss.

AdvertisementControl Begins with the Screen

It’s true with every type of screen printing: If you control the screen, then (and only then) do you begin to control the process. Advancements in stencil systems and meshes have raised the bar considerably on what can be achieved with screen printing. Many special-effect inks are quite thick (or thixotropic) and more difficult to get through the mesh than standard inks. Some water-based inks can dry in the mesh. Using a mesh with sufficient open area and reaching an adequate tension level (at least 30 N/cm2 on standard mesh counts) allows the ink to transfer to the substrate.

Most specialty inks require a low mesh count. We generally use mesh counts of 110 (threads per inch) or below. Large glitters and beads need mesh counts as low as 13 to 24. At the other end of the spectrum, mesh manufacturers have realized that garment printers can also take advantage of the thin-thread mesh technology developed for other markets. At a reasonably high tension of 25 to 30 N/cm2, the smaller thread really helps increase the open area of the screen. With thicker specialty inks, 80/70 (80 threads per inch with a 70-micron thread diameter) can be the most effective mesh count. The 80/55 mesh is useful because the smaller thread diameter allows ink to more easily pass through the stencil, but it can be very fragile. Water-based inks work nicely with thinner meshes, including 150/48 and 225/40. With meshes ranging from 305/30 to 350/30, we can even run water-based simulated process halftones as fine as 85 lines per inch.

The skeleton’s eye and hat detail feature an HD clear with a bronze ink sandwiched in the layers.

Remember that the combined thickness of the mesh and stencil is directly related to ink deposit. If we want a softer, smoother, or thinner print, we use a higher mesh count with a thinner stencil. Conversely, achieving prints with more texture or thicker ink deposits will require a lower mesh count with a thicker stencil. Because we often want a very thick ink deposit with some of these applications, we modify our typical coating techniques a bit for the very low mesh counts and specialty emulsions and capillary films that are involved. Capillary film is available in thicknesses ranging from 20 microns all the way up to 1000 microns; we usually stay in the range of 100 to 400 microns for best results in specialty applications. Even with extreme HD effects, it can be easier to stack two or three sheets of capillary films together rather than trying to get full release from a 1000-micron film. Most thicker films use pure photopolymer sensitizers to allow for faster screen exposures. Developing and washing out the properly exposed stencil take a bit of “voodoo” as well to clear the finer details in the image.

On-Press Considerations

Developments in ink technology and newer formulations introduced in recent years allow for a much broader range of effects than ever before, while making many of the more familiar products more forgiving in production. But there are some important printing considerations when printing these specialty products.

First, the planar relationships of the platens to the heads, squeegees and floodbars, and off-contact distance must be equal and consistent. This is particularly important for effects that require an exact ink deposit thickness. Many special-effect inks require a flash after printing if they cannot be printed last. They may require an additional cooldown station after the flash as well. In our shop, we may also choose to use a heated iron or roller with various papers to help get the textures we want at different stations within the print order. Sampling plays an important role in developing these specialty printing applications successfully. We do a lot of testing to determine the optimum placement of the special-effect screens, which in turn dictates where the flashes, cooldown stations, and on-press treatments will be.

Because we use different meshes and sometimes thicker stencils for these inks, the print can require a steady, slow flood coat with heavy pressure to fill the stencil with the ink. Then we set the print stroke at a medium to fast pace with decreased pressure to transfer the ink from the stencil to the garment. The flood and print strokes require some finesse to get just the right pressure, speed, and off-contact combination. Choosing the squeegee itself takes a bit of know-how, too. Sometimes we want a sharp though soft edge, but we obviously don’t want the squeegee to roll over. The best way to accomplish this is a triple-ply, duel-durometer blade. For textures, we frequently use 65/90/65 and 55/90/55 blades. Various squeegee profiles such as bevels or round edges can be useful in certain applications as well. With water-based inks, we often use a hard durometer such as an 80. Using different squeegees and floodbars can help you create some very interesting effects.

A rock base printed with a lift-off technique with negative off-contact, topped with foil.

Specialty applications usually require a bit more attention to drying requirements than traditional prints. The ink deposits can be much thicker, and with some water-based inks, the water must be driven off before curing can take place. Both of those conditions mean the print often needs to spend more time in the dryer chamber. Typically, the conveyor belt speed will need to be reduced to get the additional drying time required, or the temperature increased, or both. With special-effect inks, dryer settings can dramatically influence the final appearance or texture of the print. Because these inks often require different curing parameters than standard products, be sure to refer to the product data sheets. It’s also a good idea to do wash tests when trying out techniques to be certain of durability.

Keeping detailed, accurate records is critical. Documenting how the process and inks react in production is vital to success and your ability to repeat the results. Having everything as standardized as possible ensures CPR (consistency, predictability, and repeatability), a concept we learned years ago from Mark Coudray and from Joe Clarke’s book, “Control Without Confusion.”

Once you are in control of the process, then you can begin to manipulate it. Combining effects allows you to develop exciting, truly original new looks. Before trying this, take the time to learn how each effect behaves on its own and which ones work well with others. These multiple-effect applications require testing and control of as many variables as possible. Sampling and investing time in research and development will help you learn to produce these types of special effects efficiently, and are an important step in your journey to becoming a specialty printer.

There Are No Rules

Specialty applications present some challenges, but you can overcome them with some basic separation techniques, screen making procedures, ink adjustments, and on-press tricks. As Albert Einstein said, “Imagination is more important than knowledge.” Specialty printing doesn’t come in a can: The things you learn through sampling and production will be as valuable as the product information from the manufacturers. Success does require planning and careful documentation, but it also takes a willingness to break the rules.

Specialty applications present some challenges, but you can overcome them with some basic separation techniques, screen making procedures, ink adjustments, and on-press tricks. As Albert Einstein said, “Imagination is more important than knowledge.” Specialty printing doesn’t come in a can: The things you learn through sampling and production will be as valuable as the product information from the manufacturers. Success does require planning and careful documentation, but it also takes a willingness to break the rules.

Specialty printing is lucrative and customers will pay more for it, removing you from the commodity pricing model. It will improve your bottom line. Tackling these applications will also improve your skills and help you gain additional control over your process, giving you a better understanding of the production variables. It’s exciting to keep up with these embellishment methods as they evolve, all part of being a true specialty printer.

Lon Winters is the president and founder of Graphic Elephants and Print This, Inc. His nearly 30-year career in garment printing includes being named as director of production for Ocean Pacific at the age of 21. He is a frequent speaker and author, and his companies have won over 50 awards in international printing competitions. He was inducted into the Academy of Screen and Digital Printing Technologies (ASDPT) in 2013.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

Livin’ the High Life

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Latest Feeds

Advertisement

Most Popular

-

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month agoF&I Printing Is Everywhere!

-

Case Studies1 month ago

Case Studies1 month agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Andy MacDougall1 month ago

Andy MacDougall1 month agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns2 weeks ago

Columns2 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note2 weeks ago

Editor's Note2 weeks agoLivin’ the High Life

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Marshall Atkinson2 weeks ago

Marshall Atkinson2 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

News & Trends1 month ago

News & Trends1 month agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?