(SCHAUMBURG, IL) Sterling Screen Printing Inc. is a leading manufacturer of industrial screen-printed products specializing in the production of printed electronics, close tolerance membrane overlays, keypads and high-end graphics for OEM markets. This growing and successful company operates a 27,000 square foot, state-of-the-art manufacturing facility located in Shawnee, Kansas – about 15 miles from Kansas City.

(SCHAUMBURG, IL) Sterling Screen Printing Inc. is a leading manufacturer of industrial screen-printed products specializing in the production of printed electronics, close tolerance membrane overlays, keypads and high-end graphics for OEM markets. This growing and successful company operates a 27,000 square foot, state-of-the-art manufacturing facility located in Shawnee, Kansas – about 15 miles from Kansas City.

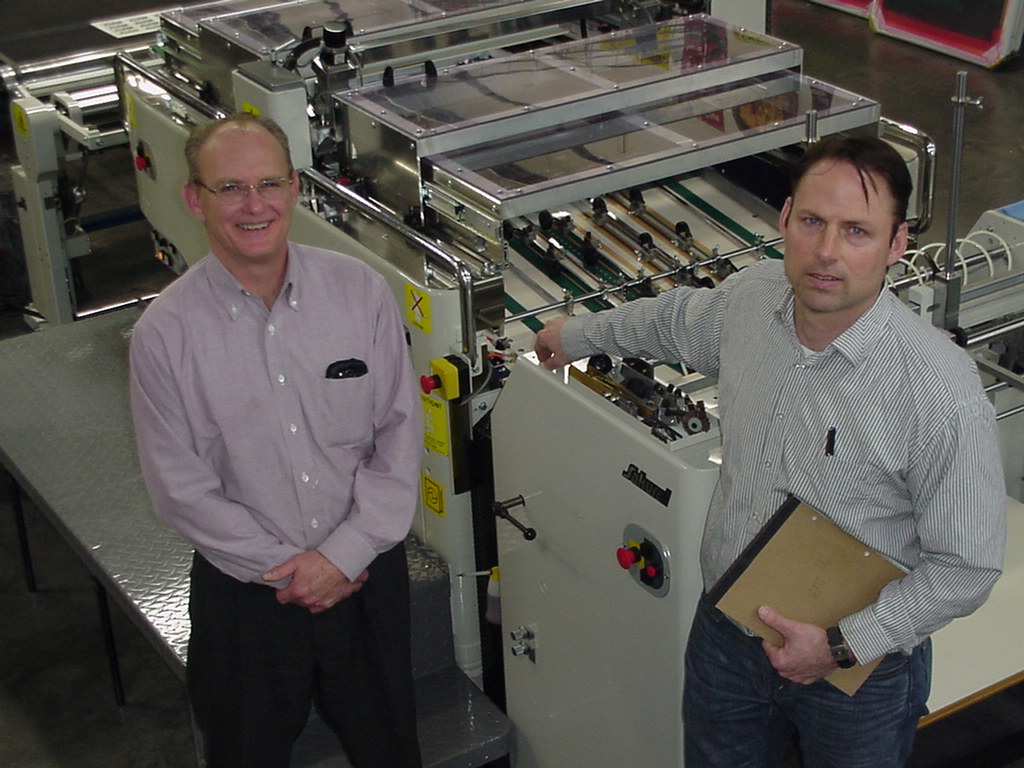

Sterling got its start 23 years ago by combining the unique talents of two individuals who knew in their heart they could do a better job of serving the OEM graphic market. Chris Routh, Sterling’s president has over thirty years’ experience in selling graphics in a custom and demanding market. And Dan Hrenchir, Chris’s business partner, is a graduate of the University of Kansas School of Electrical Engineering and gives Sterling’s customers a wealth of information to assist in design and implementation of new products.

“Together we complement each other’s talents in a way that has given us an edge over our competition,” said Routh. “If a customer wants information they can call and be greeted by an experienced staff member, not voice mail. If there is an urgent need, they can contact our team or the owners themselves anytime, 24-7 for help or resolution on emergency requirements for their production lines.”

In an effort to improve productivity and turnaround times for its pressure sensitive and overlay products, last December Sterling purchased a new, high production Sakurai MS-80A cylinder screen press from Sakurai USA.

Advertisement

“We were looking for a way to compete and build margins and that’s exactly what we accomplished with the Sakurai screen press,” added Routh. “The Sakurai press has become an integral part of what we do and it has allowed us to increase our throughput by 310%. One job that previously took us six days with three different presses could now be done in two on the Sakurai. Its extremely accurate and we can put one color on top of and another and hold a registration mark that’s 8 point type.”

The Sakurai Maestro MS-80A is one of Sakurai’s workhorse screen presses and is also ideal for heat-applied transfers, tagless labels, pressure sensitive applications and more. The high precision, high productivity MS-80A, which accepts sheets up to 31 5/8” x 21 ¾” and operates at speed up to 3,600 IPH was featured in Sakurai’s exhibit at SGIA ’13.

“Sakurai the company was awesome to work from the moment we bought the press, dealing directly with David Rose, Sakurai’s General Manager. Service and training were first rate,” Routh said. “After the press was already in service we decided to add a takeoff option and Sakurai got the part to us and had it installed within a week.”

Looking to the future, Routh observed, “The market is going to see price point pressure and margins will be challenged, but we are well equipped to compete with our new Sakurai press.”

###

Advertisement

Sakurai offers a family of sheetfed offset and cylinder screen presses for every size and need. Fully automated Sakurai sheetfed offset presses are available in two thru six-color configurations in widths from 20" X 26” to 23 5/8 x 31 1/8” with coating and perfecting. Sakurai ultra high precision screen cylinder presses are available in sizes from 20½” X 28½” to 48” X 63”. Sakurai presses are distributed in the U.S, Canada, Mexico and Central America by Sakurai USA, backed by an Experienced Dealer Network, responsive customer support, service, parts and training.

Art, Ad, or Alchemy1 month ago

Art, Ad, or Alchemy1 month ago

Case Studies1 month ago

Case Studies1 month ago

Andy MacDougall1 month ago

Andy MacDougall1 month ago

Editor's Note1 week ago

Editor's Note1 week ago

Columns2 weeks ago

Columns2 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Marshall Atkinson1 week ago

Marshall Atkinson1 week ago

Press Releases2 months ago

Press Releases2 months ago