Case Studies

The Big Score: High-Stakes Hot-Market Printing

The duty of printing souvenir items for championship-winning teams is chaotic and thrilling.

Published

6 years agoon

BEEP, BEEP, BEEP.

The hotel alarm goes off and one thought runs through my mind: Game day.

It’s January 8; tonight is the 2018 College Football Playoff National Championship game. In less than 12 hours, the Georgia Bulldogs and Alabama Crimson Tide will battle it out for that coveted national title at Mercedez-Benz Stadium in Atlanta.

So what exactly brings this Purdue Boilermaker fan (hey, at least we made it to a bowl game this season!) to Montgomery, Alabama – right in the heart of Bama territory – on the day of the Division I football championship game? The promise of seeing a hot market live in action.

I’d been pursuing such an opportunity for a while. An email sent a few days before the game quickly turned into a last minute plane ticket and hotel reservation in Montgomery, home to F&E Sportswear, the print shop tasked with printing shirts for the national championship game. “Last minute” is the very nature of hot-market printing – the apparel industry term for when a contract printer takes on the hefty (and often chaotic) duty of printing souvenir or keepsake items for the winning team in a championship game. The kicker? Fans celebrating a big win want to buy their shirts ASAP. We’re talking about having these special edition T-shirts available for purchase the morning after the game.

With the participants usually determined by other semifinal games (generally only a few days or weeks prior), it’s difficult to do much advance planning. Being able to work quickly and efficiently (and stay cool under pressure) is key. It takes a certain type of shop to thrive in this high-stakes environment.

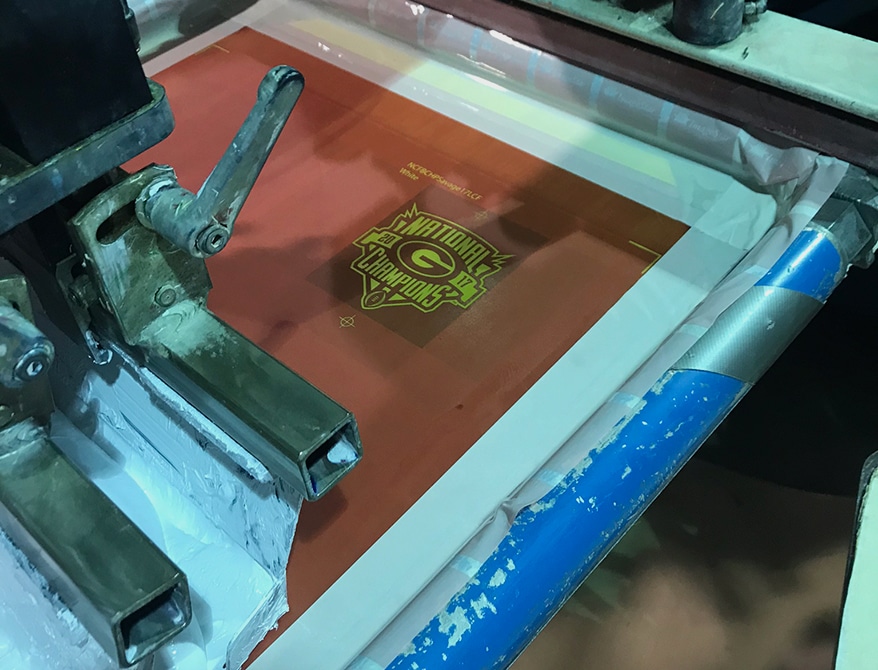

A test print of the Georgia back design.

F&E Sportswear, a family-owned medium-size shop specializing in screen printing, embroidery, and specialty advertising, is no stranger to hot-market printing. “We started hot markets the same year that [University of Alabama’s] Coach Saban won his first national championship; that was in ’09,” Rodney Tidwell, F&E plant manager, recollects. “Chaos would be a good word for that first time.” The shop now averages two hot markets per year, and has developed a system Tidwell classifies more as “organized chaos.” The shop is contracted with New World Graphics (which in turn is contracted with both Auburn and Alabama) for the annual Iron Bowl rivalry game hot market, and usually one or both of those teams are in the SEC football championship game. As the saying goes, practice makes perfect (or at least, as close to perfect as a hot market will allow).

The Game Plan

With the countdown to kickoff less than 12 hours away, I make my way to F&E’s shop on the north side of the state capital to see just how much prep work can be done before the game. After a very confused Uber driver drops me off at F&E Sportswear – and not AB Sportswear, located directly across the street – Tidwell gives me the grand tour of the facility.

By now, F&E is in full swing, from the art department to the showroom to the shop floor. Clarence Smitherman, graphics supervisor, is in the art department offices on the phone with their agency, New World Graphics, sorting out some last minute artwork details: Georgia ordered 13,000 red shirts, but the job ticket that came in this morning also calls for charcoal shirts. The final approved artwork was designed for printing onto red, so prints onto charcoal T-shirts will require some tweaking – preferably sooner rather than later. “We’re trying to get our ducks in a row before it’s crunch time,” Smitherman explains. “Sometimes it goes as smooth as smooth can be, and other times, not so much.”

A Georgia left chest on press during a test run.

Smitherman does what he can to make things run as smoothly as possible. He calls himself the “problem guy,” looking for any issues that could occur during a run before the printing starts. “You get in a hurry, you get tired, you’re 10 hours in, and mistakes start happening,” he says. “When we do our art here, we try to set it up so that we can run different color shirts at one time instead of having to drop plates and add plates.” Simplicity will certainly be appreciated by the press operators tonight at 3 a.m. when printing is in full swing.

Since the artwork for tonight’s hot market requires approval from outside entities, Smitherman hopes to have the final design ready to go in the next hour or two so Darrel Scott, print manager, can set up as many presses in advance as possible. Because both teams’ T-shirt designs require the game’s final score (Bama’s design is what Smitherman calls a “recap shirt,” with the scores of every game of the season on display – “which, as Alabama fans, we wouldn’t really like to have the Auburn score on there” since the Tide lost that game), at least some screens will have to be made after the final whistle blows.

Take a tour of the shop as the team preps for the hot market the morning of the big game.

Out on the shop floor, Scott and the production crew are setting up the four presses that will be running the overnight job. “We’ve already burned the Georgia design and the left chest,” Scott tells me over his shoulder as he gives me a tour of the screenroom. This is where the magic happens: I watch as the screens with both designs for tonight are exposed, washed out, dried, and taped, ready to go.

I learn that F&E is in a fortunate position to be contracted to print the T-shirts for both teams involved in the game. Oftentimes, a shop only has the license to print apparel for one team, so if they are doing the hot market and that team loses, all of the time and prep work was for naught. “Last year, we were set [to print] for Alabama [for the National Championship game] and it was a heartbreaker when Clemson scored with one second left,” Tidwell remembers. “I mean, we’ve got everybody here, presses are ready set to go, and Clemson scores. I had to walk out back to let everybody go home.” Though the diehard Tide fans on the crew may not like the team on the shirts they’re printing tonight, they can rest assured that there will be work to do.

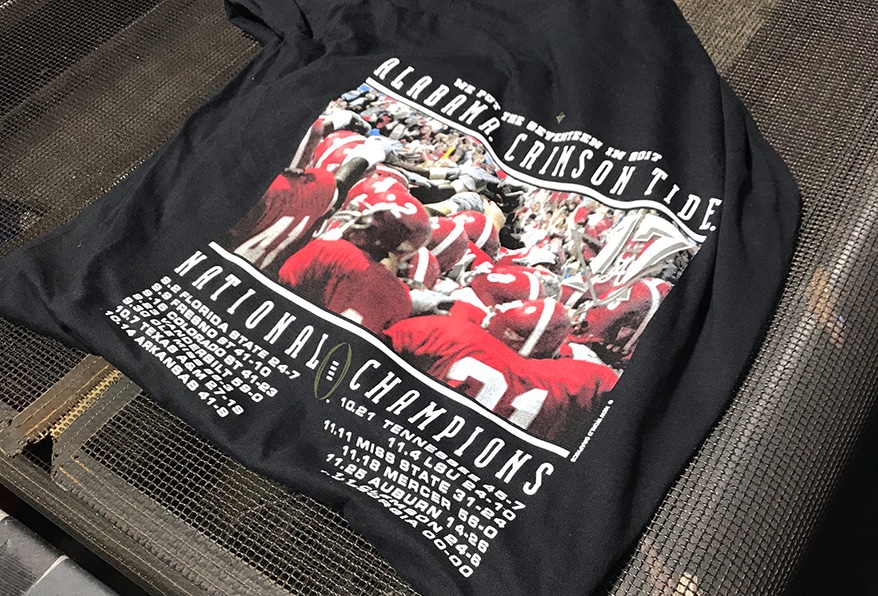

An Alabama test print.

Another common hot-market strategy that F&E has employed in the past is printing “kill” shirts. This approach involves printing thousands of shirts for a team expected to win – say, the Purdue Boilermakers – with no score in the design, and sending boxes labeled “Do Not Open Unless Purdue Wins” to large stores such as Hibbett Sports or Dick’s Sporting Goods. If the team wins, then the store is ready to start selling T-shirts in the morning. If the team loses, the shirts either get thrown away or sent off to a developing country, since they can’t be released anywhere in the US. Tidwell tells me F&E has taken this gamble and lost one time, printing 5000 undistributable Kentucky Wildcats shirts before Wisconsin beat the undefeated UK basketball team in a nail-biting 2015 NCAA Tournament Final Four game.

With the reassurance that thousands of shirts must be printed tonight one way or another, the crew strategically arranged a Georgia Bulldogs left chest design on one end of the screen (“Just in case,” Scott laughs. “I think Bama will probably win.”) and an Alabama left chest on the other end. Regardless of the winner, the front left chest design will have white-highlight white-black ink, “so this way you only utilize a total of three screens for the whole set,” Scott explains. He’ll set up two presses (a 16-color M&R Sportsman EXG and 12-color Gauntlet II) on the left chest design before the game tonight, and quickly tape up the losing team’s portion of the screens when the score is final.

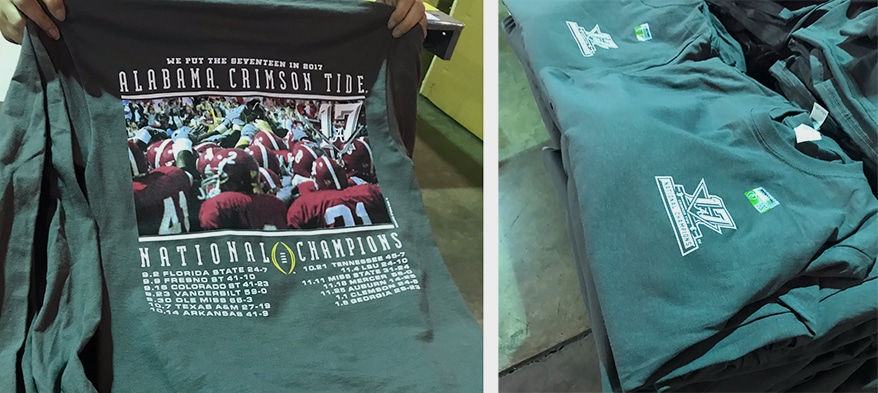

Final screens taped up and ready for printing.

The remaining two presses are being set up with each team’s winning design for the back of the shirts. Georgia’s design is a relatively simple 4-color (white, highlight white, black, and liquid gold) print onto red and charcoal shirts – by now, Smitherman has gotten the OK to tweak the design to work for the second shirt color. Alabama’s, on the other hand, is a 10-color, photorealistic score recap design for 14,000 black and charcoal T-shirts, which means two different underbases; a bit more complicated to set up, but not a problem once things get moving, Scott assures me. He’s done a couple test runs for both colors to ensure the designs themselves and the presses are both ready to go with no issues.

There’s a commotion in the unloading area, so Scott and I walk over to check it out. A truck has arrived with blank shirts for tonight’s hot market. “We usually get all of this in house two or three days prior,” Scott comments. But with a hot market, things never seem to go quite as planned; thousands of T-shirts are still missing, and at least one box has the wrong color shirts. “The hard part is getting all the pieces of the puzzle together at one time,” Tidwell adds. “Missing 8000 shirts is a pretty big deal right now.”

“Maybe they’re just sitting across the street [at AB Sportswear],” Scott laughs. “It happens.” I make a mental note to tell my Uber driver he’s not the first one to make that mistake, if I happen to see him again.

I notice a huge stack of boxes along the wall and Tidwell explains these are all the unused shirts from the recent Iron Bowl and SEC championship hot markets. “That’s one of the agreements [we make with our suppliers]: for the team that doesn’t win, they will take the shirts back without a restocking fee,” says Tidwell.

With the game kicking off in about nine hours and the overnight crew heading home to get some rest before the big night, I decide to do the same and head back to my hotel while Tidwell and Scott sort out the mystery of the missing shirts. The anticipation and excitement in the air is almost palpable as the crew of Alabama fans (and seven or eight Auburn fans who will be rooting for Georgia tonight, as they always do when their team is out) finish up their work.

Take the Ball and Run

After finishing up the rest of my usual workday and ordering a delicious room service dinner, I switch on the TV to catch the start of the big game. After a scoreless first quarter, Georgia starts pulling away in the second quarter with a 13-point lead. Around 10 p.m., I mentally prepare myself to spend the night with a bunch of bummed out Alabama fans as I make my way back to the shop to watch the “organized chaos” of the hot market live.

The mood isn’t quite as grim as I expect it to be when I join the production crew in the break room to watch the rest of the game on a big screen TV. Alabama let the Bulldogs score another touchdown, but then added 10 points themselves during my ride over (The missing shirts were tracked down in my absence, so that likely helped lighten the mood.). This is just enough to make the Georgia fans nervous and the Bama fans hopeful. In the fourth quarter, the Crimson Tide evens up the score, only to miss a game-winning, last-second field goal and push the game into overtime. I’ve never seen such anxiety, frustration, and pure excitement over a football game – and I’ve been to my share of Big Ten rivalry games.

Multiple carts move T-shirts in varying stages of completion from press to press and from dryer to folding and sorting station.

In overtime, Georgia takes back the lead with a 51-yard field goal. As everyone in the conference room (and others around the country) watch with bated breath, Alabama’s Tua Tagovailoa throws a 41-yard touchdown to secure a Bama victory with a final score of 26-23. Amidst cheers of victory and yells of disappointment, I run after Smitherman as he quickly heads to the art department to finalize the Crimson Tide’s artwork and kick off the long night of printing ahead.

Tackling 14,000 Shirts Overnight

As the production crew starts warming up the presses and tearing down any Georgia screens, Smitherman fires up his computer, closes out of the no-longer-needed Bulldogs design, and confirms the final score online – three times, just to be sure. “I’ve seen people who have printed 20,000 shirts with the wrong team or the wrong score,” Scott warned me earlier in the day, and F&E is careful to circumvent such a costly – and avoidable – mistake. Confident Alabama secured victory by 26 to 23, Smitherman adds the final score to the lower right corner of the design to complete Bama’s 2017-2018 season, saves the file and uploads it the server, and hurries out to the screenroom.

A glimpse into the organized chaos of hot-market printing.

We meet Scott at the company’s i-Image CTS Imaging System as the winning design loads and is output and exposed onto the final screens. Almost dizzyingly fast, the screens go from the CTS unit to the washout booth to a vacuum and a fan for drying before they’re taped up and loaded onto the presses running the backs of the shirts: a 16-color M&R Gauntlet III and 16-color Performer.

The two presses printing left chests are already up and running out on the shop floor, with production crew members carting shirts around the shop. I wander over to one of the presses in the final stages of setup for the 10-color design, where Richard Patiño, executive VP, is meticulously checking registration marks.

“Everything was set up beforehand except for the last three screens, so now we just have to line everything up,” he says. Speed may be the name of the game, but for F&E, it comes down to quality. As Tidwell told me earlier in the day, “Good enough is not good enough. We want it to be the best.”

As it turns out, F&E isn’t the only place where these designs will be printed tonight. A partner print shop about 20 miles from F&E’s facility has also been contracted to print championship shirts onto Cardinal-colored T-shirts, putting additional emphasis on getting everything right. “Consistency is key,” Scott explains. “I don’t want one guy to say, ‘Well, I can tell Mario ran this one.’ We want all of it to look exactly the same.”

Midnight approaches and printing is now underway on all four presses. As shirts continue to churn out, are carted from press to press, and go through the dryer, Bama and Georgia fans alike start to settle into the groove of things, cranking out close to 1000 shirts per hour. Finalized T-shirts receive an Officially Licensed Collegiate Product hologram sticker to prove authenticity and are then folded and moved to the unloading area to be sorted by size and boxed or bagged up, according to order. More than 250 separate shipments will be prepared and picked up by the morning, with the first trucks arriving to gather their goods around 1:30 a.m. Fans will be arriving at sporting goods stores in the morning eager to purchase their Alabama National Champions shirts, so time is of the essence.

Still going strong on the adrenaline rush of a last-minute victory (or perhaps all the caffeine from the empty Mountain Dew bottles and cappuccino cups from the breakroom I see strewn around the shop is starting to kick in), the whole crew whoops and hollers when someone starts blaring the Alabama fight song. I can tell it’s going to be a long but fun night (or maybe the more accurate word is “day” since the crew will be printing until 1 p.m.) of hard work. As the clock edges closer and closer to 2 a.m., I decide it’s time for this journalist to get some shuteye before the long trip home in a couple hours – that is, if I can fall asleep after the excitement of the day. One thing is for certain: I can now count myself among the few who truly understand just how much work goes into getting shirts into the hands of consumers the day after a big game.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

The Profit Impact of a Market Dominating Position

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Latest Feeds

Advertisement

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?