Inks & Coatings

Published

22 years agoon

Ultraviolet (UV) curing technology and its use in screen printing has evolved from infancy in the 1960s to maturity in the 1990s. Improvements in raw materials and better understanding of the UV-curing process made a substantial impact on ink-performance characteristics and led to greater acceptance of the technology among printers.

Ultraviolet (UV) curing technology and its use in screen printing has evolved from infancy in the 1960s to maturity in the 1990s. Improvements in raw materials and better understanding of the UV-curing process made a substantial impact on ink-performance characteristics and led to greater acceptance of the technology among printers.

As printers, we are inundated with dozens of important choices when working with UV. We not only have to select the right ink for particular materials, but have to make decisions about the curing equipment and the various lamps we may need in order to achieve successful results.

For those of us who explored the use of UV when the technology was in its infancy, lessons came in a variety of ways but were based mostly on trial and error. We had to make UV inks work and learn how to get the order out the door while trying to understand the hows and the whys behind the technology. But thanks to ink manufacturers, curing-unit manufacturers, substrate suppliers, and printers who were diligent in communicating with one another, the materials and processes involved in UV curing have become much better understood.

This article will try to explain some of the mysteries and myths of UV curing typically confronted by printers who are new to the technology. These mysteries and myths are based on the most common questions and misunderstandings surrounding UV inks and curing equipment.

UV mysteries

The mysteries behind UV relate to scientific facts and principles that are not widely known or understood. These mysteries typically involve ink chemistry and polymerization, the function of curing units, and processing considerations.

How are UV inks different from conventional inks? If we were to compare two buckets of ink, one with conventional or solvent-based and the other a UV ink, we would find that there are three major types of raw materials that go into the inks’ chemistry. For a conventional ink, they are resin, pigment/additives, and solvent. In a UV ink they are resin, pigment/additives, and monomers.

For a chemist who is told to formulate an ink, the first raw material to select is the resin. Resins give the ink its major characteristics, such as adhesion and flexibility. Solvents (for conventional ink) and monomers (for UV ink) are selected to dissolve or "cut" the resins and pigments in the formula to a workable viscosity. Solvents and monomers are also selected to complement the resin in achieving the desired performance characteristics of cured or dry ink film. Finally, the additives contained in these inks are substances such as pigments (for color), flow agents, thickening powders, retarders for conventional inks, and catalysts for both conventional and UV formulations. In UV inks, these catalysts are photoinitiators.

UV inks employ photoinitiators ("photo" referring to light or radiation, and "initiate" meaning to start) to trigger the reaction that allows monomers and resin to bond and create the cured ink film. The photoinitiators absorb UV energy at certain wavelengths, creating "free radicals." The free radicals connect with the molecules of the resins and monomers, and they, in turn, cross-link with each other, forming chains of molecules we recognize as the "cured" ink film. Chemists call this cross-linking reaction polymerization.

UV inks are considered "100% solids" because almost everything in them is used up in the polymerization process. In conventional inks, solvents are evaporated and the cured ink film comprises only what remains.

One of the major advantages of UV over conventional inks is that no volatile organic compounds (VOCs) are released into the air during the curing process. When drying conventional inks, however, VOCs are evaporated with the solvents. Additionally, because UV curing relies on polymerization rather than evaporation, UV inks can be cured much more quickly and in less space than solvent-based inks. Finally, the lack of solvent in UV inks allows them to be used with higher mesh counts and support finer detail and higher print resolutions.

What does a UV-curing unit do? The function of the curing unit is to deliver the UV energy that sets off the photoiniators and starts the polymerization process. However, before we explore just how this energy is delivered, it might be beneficial to review the nature of electromagnetic energy.

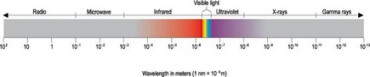

The electromagnetic spectrum exists as waves of electric and magnetic "particles" that travel through air, vacuum, and other substances. Electromagnetic waves are characterized by their frequency (number of waves per second) and associated wavelength (distance from wave crest to wave crest). Frequency is measured in gigahertz (GHz), and 1 GHz equals 1 billion cycles/sec. Wavelength is measured in nanometers (nm), and 1 nm equals 1 billionth of a meter. The electromagnetic spectrum (Figure 1) is a continuum of electromagnetic waves, all of which, with the exception of visible light, cannot be seen with the naked eye.

$image1

In the near-visible range of the spectrum, we find the range of wavelengths identified as UV. The UV range occurs at approximately 10-400 nm. The photoiniators used in UV inks typically react to specific wavelengths within the 200- to 400-nm range. However, the wavelengths that drive the curing reaction vary for different ink systems depending on what applications the inks are designed for. This is why UV-curing systems support different lamp types that deliver specific frequencies of UV energy. We’ll discuss curing lamps in more detail later in this section.

For UV inks to cure properly, they must not only be exposed to the right wavelengths of UV energy, but also to the right amount of energy delivered at the correct intensity. The amount of energy arriving at the surface of the printed substrate is called the dose and is measured in millijoules (mJ)/sq cm. The dose of energy a UV print receives is affected by the conveyor speed and number of lamps in the curing unit, as well as the number of times that it is exposed to the curing environment (such as in the case of multicolor UV prints).

The intensity of energy emitted by curing lamps is known as irradiance and is measured in watts (or milliwatts)/sq cm. Irradiance is directly related to electrical power, lamp condition, and the geometry of the reflector that directs and focuses the lamp output. Irradiance does not vary with exposure time.

The depth of cure achieved in the ink film is directly influenced by the irradiance level of the lamp. Delivering higher, more intense energy at the surface of the ink will allow more energy to penetrate the thickness of the ink film.

In curing units, the lamp and reflector assembly that delivers the UV light is call an irradiator. The lamps used in curing units generally consist of mercury vapor contained in a transparent quartz envelope. The lamps are powered in one of two ways. One type has electrodes at each end. When electrical current is applied, an "arc" is formed within the lamp, causing it to emit UV energy. The other type of lamp is electrodeless and ignites the gas with microwaves. In this system, a microwave-generating unit is placed above the irradiator and the microwaves are directed to the lamp by waveguides.

The medium-pressure mercury lamp is the most common lamp used for curing UV screen-printing inks. Argon gas and an exact amount of mercury (to create the right pressure when vaporized) are captured in a tube of fused silica. As Figure 2A shows, vaporized mercury emits ultraviolet energy at certain wavelengths so that when UV inks with the proper photoinitiators are exposed, cross-linking (curing) results.

Research has revealed that the addition of compounds called metal halides to the mercury enhances the spectral output of the lamp. This enhanced output is advantageous for curing opaque ink systems and those containing the white pigment titanium dioxide (TiO2). Two such "doped" lamps include the iron and gallium varieties (see Figures 2B and 2C). Most curing units offered today are designed to allow lamps to be changed in a matter of minutes.

One factor that has the greatest impact on the curing efficiency of the lamp is the amount of electrical current that flows through it during operation. According to Ohm’s Law, volts x amps = watts. However, to calculate the actual power that the curing unit is receiving, watts must be multiplied by the "power factor" for the particular area (this factor can be supplied by the local electric company), and divided by the length of the lamp. The result is the exact power that the lamp is receiving, provided that there are no power fluctuations.

Curing units employ reflectors with different physical geometries to focus or scatter the lamp output across the print. The specific configuration of the reflector influences how the ink film is cured. Three main reflector geometries are used today (Figure 3):

• elliptical, which concentrates energy at the print surface with a narrow focal width

• parabolic, which reflects energy at a slightly wider focal width

• multifaceted, which reflects energy at the widest focal width

One final consideration about curing equipment concerns heat management. High temperature created by the IR energy UV lamps emit is an unfortunate byproduct of the curing process. Preventing this heat from building up and damaging sensitive substrates is a critical concern in UV curing. Systems for heat management in modern curing units run the gamut from water cooling systems and fans to dichroic mirrors (which reflect UV but absorb IR energy) and automatic shutter systems.

What processing issues must be considered when using UV? In screen printing UV inks, controlling ink-film thickness is of paramount importance. Mesh type, screen-tension level, emulsion thickness, and related screenmaking factors all contribute to the amount of ink deposited on the substrate. These variables have to be controlled in order to consistently achieve the ink-film thickness recommended by the ink manufacturer. Similarly, press-setup parameters must also be controlled, including squee-gee hardness, screen off-contact, and squeegee/floodbar speed and pressure.

The type of substrates you are printing on also influences the results you can expect from UV curing. On polycarbonate substrates, for example, UV energy at shorter wavelengths (below 300 nm) tends to affect the substrate surface. This phenomenon, known as photo-oxidation, appears as a gradual yellowing of the polycarbonate surface that occurs with repeated exposure to the UV energy. The subtle change in the polycarbonate surface affects ink adhesion, especially if multiple colors are printed. However, the use of gallium lamps, which release UV energy in the shorter wavelength range, has been shown to minimize this photo-oxidation of polycarbonate.

Polyester is another material commonly printed with UV. The main factor to keep in mind when working with po-lyester is that this material needs to be pretreated (flame or corona treatment) or coated with some form of primer to achieve good ink adhesion.

The last issue in using UV technology is safety. While UV inks aren’t characterized by dangerous solvents, the monomers they contain can cause allergic reactions in users who are sensitive to this chemistry. Monomers used in UV inks are tested for toxicity (skin irritation) and assigned a rating from one to ten, where one is least toxic and ten most toxic. But even with low-toxicity monomers, it is always a good idea to wear protective clothing, including eye and hand protection, when handling UV inks.

Besides UV energy, UV lamps also emit very bright visible light that could be harmful to the eyes if workers are exposed to it frequently or for long periods. This is why it is important to block light from escaping through the curing-chamber conveyor openings by installing shields.

One other safety issue to keep in mind concerns ozone, which is a very unstable molecule of oxygen. Ozone is generated when an electric discharge passes through air (e.g., lightning) or when oxygen is exposed to high-intensity UV energy. Ozone generated by curing units can lead to respiratory problems for those who work near the curing units, so it’s important to make sure that curing units are well vented to evacuate ozone from the work area.

UV myths

Now that we’ve explored the mysteries of UV technology, let’s clear away the myths that surround it. These myths are widely held beliefs that, upon closer examination, are not grounded in scientific facts or principles and can’t be supported by logic or practicality.

When printing multiple colors, undercure the first color to prevent it from becoming overcured when successive colors are cured. Undercured UV ink exhibits adhesion problems. When the ink layer at the bottom is not thoroughly cured, it will remain undercured regardless of how many passes it makes through the curing unit. The problem is that printing another layer of ink on top of the undercured ink will inhibit any more UV energy from penetrating to the ink interface. With undercured ink the possibility of the top layer rewetting the bottom layer is also a concern. Each and every layer of ink must be thoroughly cured.

Depending on the ink system, certain colors within the system will have the tendency to cure faster than others. By the same token, certain ink systems will cure more slowly than others. Ink-manufacturer recommendations and your own experimentation will help guide you to the proper curing parameters for each ink line and color you use.

The inks should cure properly because my "puck" (radiometer) is showing the correct millijoule reading as recommended by my ink supplier. Radiometers are useful tools in measuring energy output. However, there is no correlation between numbers measured by different radiometers for the same curing unit. Employing the same radiometer to measure various curing units in the same shop is useful only for comparative purposes.

Ink manufacturers may have a published range of ideal curing conditions that were determined under controlled laboratory conditions, and these can serve as a starting point for your own measurements. Just keep in mind that in screen printing, where ink-film thickness can vary, the number of millijoules and, more importantly, the milliwatts necessary to cure an ink will also vary.

The lamp is bright, so it is still good. A UV lamp emits three different energies: ultraviolet, visible light, and infrared. As the lamp ages, the brighter and hotter it becomes. Simultaneously, the ultraviolet energy emitted by the lamp decreases. Since ultraviolet energy is invisible, regular measurement with a radiometer and good record keeping with a radiometer is the only way to ensure that UV lamps are operating correctly.

The ink is bad because it is not sticking to the material. There is a fine line between adhesion and cure. Ink film that is not cured thoroughly will not adhere to the substrate. Assuming you’re printing a colored ink rather than a clear coat, you can determine whether the problem is adhesion or cure by slowing the conveyor speed and increasing lamp wattage. In other words, you eliminate curing as a variable by curing the dickens out of the ink. If the ink still doesn’t stick, you know you’re dealing with an adhesion problem.

You can also print a clear coat and check for adhesion (using the cross-hatch and tape test or a similar method). The clear coat should cure faster than pigmented inks, so if the clear adheres to the substrate but the colored ink does not, then the problem is cure. If the clear ink film lifts from the substrate like a banana peel, then the problem is adhesion.

The ink has a different smell; therefore, it is not good. Every UV ink has its own distinct smell in the container, depending on the monomers that are used in the ink. Smell has very little to do with the ink’s performance. If smell is an issue, odor-masking agents may be added to the ink during or after manufacture.

All curing units are the same. Performance differences always exist among curing units, even in models from the same manufacturer used in the same production area. Among other things, these differences can stem from lamp age, use of different reflector geometries, and differences in the way the curing equipment is maintained.

Make UV work for you

UV technology gives screen printers the capability to print faster, more efficiently, and more accurately on a wide range of materials. But to realize the full benefits of UV, users must understand the nature of UV inks and the equipment required to cure them. UV technology leaves little margin for error, but through testing, regular measurement of curing conditions, and accurate recordkeeping, you can enjoy all the advantages that this technology has to offer.

About the author

Bea Purcell is product manager for Nazdar, Shawnee, KS. She has more than 18 years experience in screen-printing and UV-curing technology and has held positions in technical services, ink research and development, training, sales, and marketing. Purcell holds a bachelor of science degree in chemical engineering from the University of San Carlos and a master of science degree in education from the University of Southern California.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?