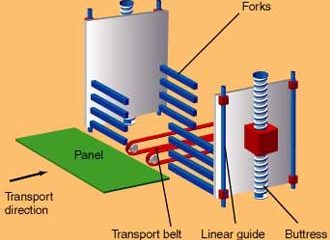

If your prints suffer from ink-adhesion problems caused by surface contamination from dust and particulates, or if you’re having issues with media sticking, binding, or misrouting,...

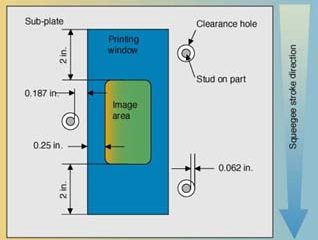

Screen printers who push the envelope in production volume often find themselves limited by the size and configuration of their presses. Even using the maximum screen...

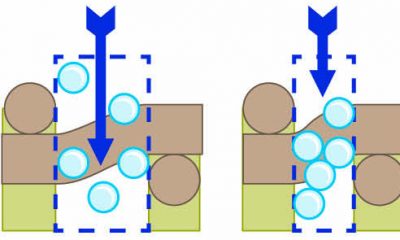

Understanding key variables in the screenmaking process is the only way to guarantee optimum stencil exposure in screenmaking and performance on press.

Becoming familiar with how special-effect inks work is critical to printing them successfully, no matter how long the job run. Experimentation aids in determining how special-effect...

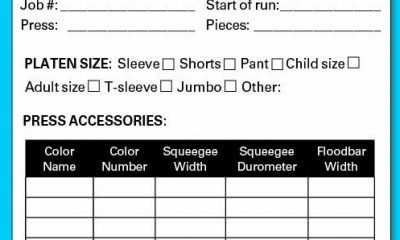

Staging is the gathering of required tools and materials in a physical location in readiness for the succeeding steps of the production process. Staging a garment-printing...

Dye migration is an unwanted reaction between plastisol ink and the dye used in the garment fabric—polyester fabrics and blends, in particular.

Graphics applications can vary widely, and not many universal rules exist when choosing a media on which to print. There are many factors to consider, from...

Inkcups Now Corp. (ICN) is excited to announce the opening of new World Headquarters to accommodate company’s growth and further optimize production processes. As of January...

You might already be using Facebook, Twitter, and other social-media sites to tell the world what your shop is doing (and if you’re not, you really...

Basic alignment of major press components is a consideration that’s often overlooked. That’s unfortunate, because it can have a major impact on your ability print graphics...