TO MAKE IT IN this business, a screen printer needs a press (manual or auto), a heat press or dryer, an exposure unit, a washout booth, inks, screens, emulsion, software… the list goes on. Finding the right products and the right provider for the applications you print can be a daunting task. Before starting from zero, why not look at what tools your peers are raving about? Here’s what 30 of Screen Printing’s Brain Squad members have to say about the technology they can’t live without.

“I like Anatol electric autos, Riley Hopkins manuals, and Union Mixopake Mixing System,” says Eric Courtemanche, Revision Screen Printing.

“I like Anatol electric autos, Riley Hopkins manuals, and Union Mixopake Mixing System,” says Eric Courtemanche, Revision Screen Printing.

- Riley Hopkins Press! This has been the press I had always wanted since the start. It was kind of like a relationship. When you first start, you’re really picky. You just want one so you can start getting down on it. It’ll last a while, little repairs here and there, but you knew it was time to upgrade because you’re better than that. Then along comes a better press. One that someone got tired of. So, you think you’re Superman and swoop in the pickup. Kind of like the movie “La Bamba,” when Ritchie met Rudy, the singer of The Silhouettes. Rudy says “What’s that? Looks like something someone threw away.” Ritchie replies, “It’s mine now, so don’t worry about it.” So, you keep that one for a bit, then one day you see the Riley press… shining like the sun shining on a bald man’s head!! Too much? I’ve also been making my own squeegee from my 3D printer. — Rene Cantu, 361 Printing & Embroidery

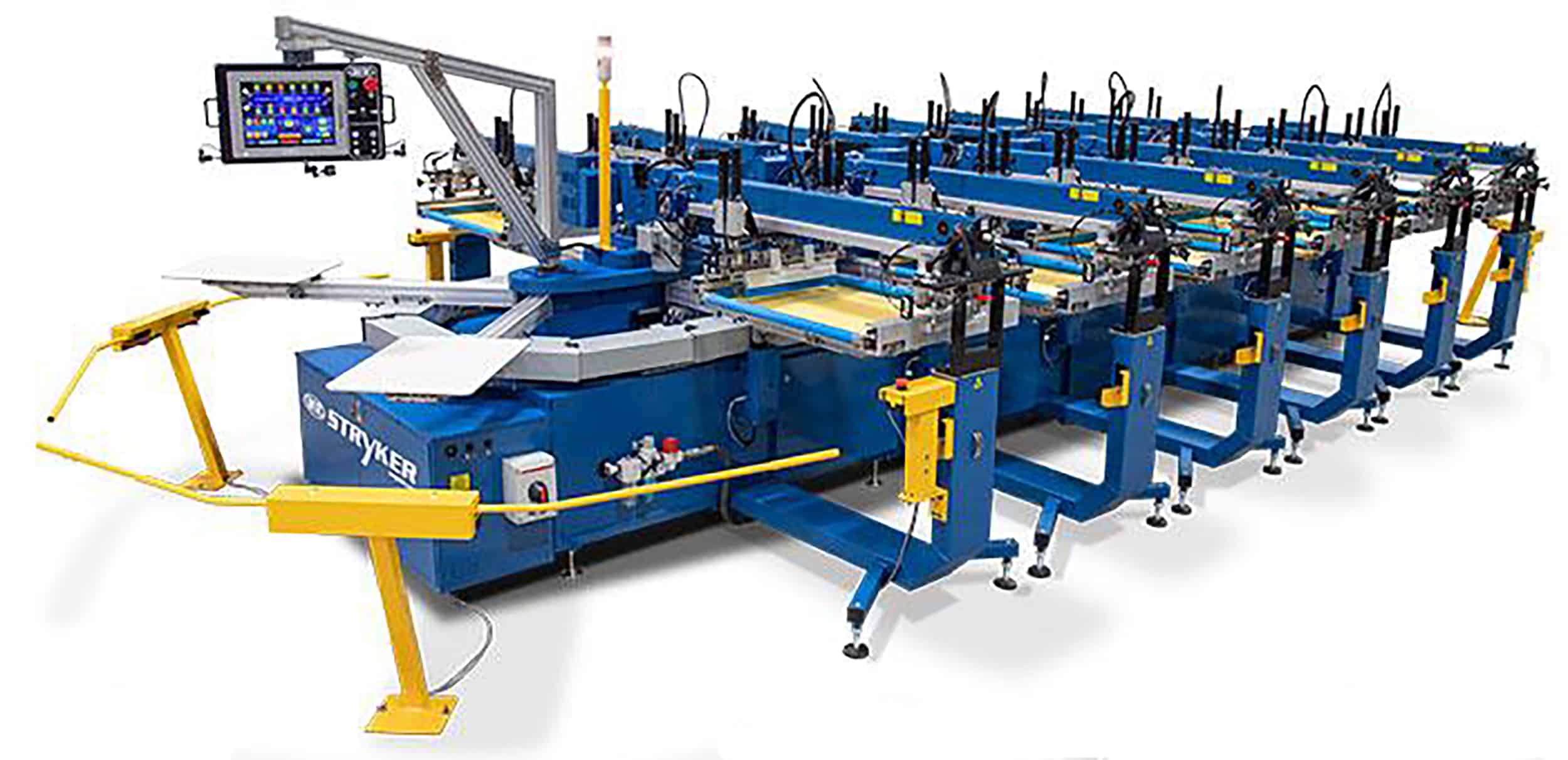

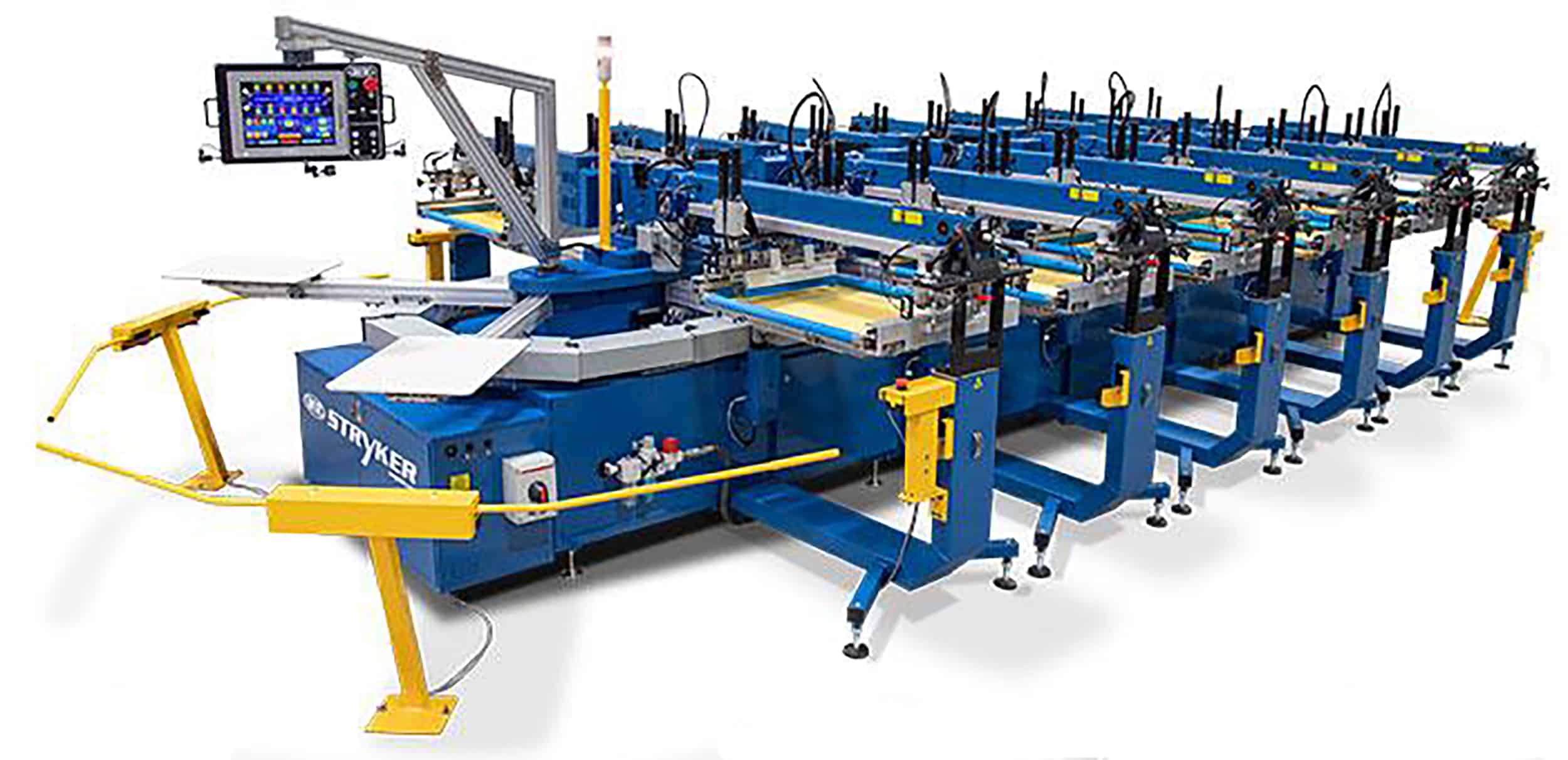

- We use M&R equipment. They are easy to repair, and many parts are available locally. Newman Roller Frames allow us to keep our screen tensions where we want them to be. Wilflex inks have a great mixing system and are quality inks. The addition of a roller station to smooth our white underbase has made a huge difference in our quality and feel of the print. Every automatic press should have a roller to smooth your underbase. Gildan Hammer is my favorite shirt to wear. At six ounces, it is too heavy for some. The Bella + Canvas 3001 is a very nice shirt for a fit body. Port & Company PC54 – The price is right for many of my customers. Next Level 3600 unisex T and N1533 women’s tank sell great in bars and breweries. — John Wilhelmsen, Distinct Impression

- We like One Stroke inks because they are high quality. Here’s the details from my best lady, Kat, my screen printer: She loves One Stroke Inks, wooden squeegees, and the Brown Electra Print. She also loves printing on 50/50 cotton poly blend tees. — Maude Swearingen, Fully Promoted Arbutus

- Vertex Apparel. They have such nice shirts that are in stock and readily available. TagBot by Livingston. I’m able to print in one rotation a neck tag and a full color front. The TagBot system saved me a ton of time on labor, printing, and tag prints. Took about an hour to get used to it, but it’s absolutely worth the investment. I’ve been able to blast out 9000 shirts in record time with custom tags within a day’s time vs. four days with my old system. If you’re printing in the neckline, check it out, and get one. Mine already paid for itself. Probably adding another by late fall! Alex from Easiway makes it easy, too. — Ron Augelli, WeTalkShirty.com

John Wilhelmsen of Distinct impression says M&R equipment is “easy to repair, and many parts are available locally.”

John Wilhelmsen of Distinct impression says M&R equipment is “easy to repair, and many parts are available locally.”

-

- We are a full M&R facility. We use M&R equipment because it is good quality and they are very easy to work with. They always take care of us, so our production is down the shortest time possible. We very seldom have any equipment down more than a day. Rich Hoffman was a great guy to work with. They just have solid equipment and very few problems. — Al Messier, Team Print

- Ryonet. — Maxwell Beehner, Family Industries

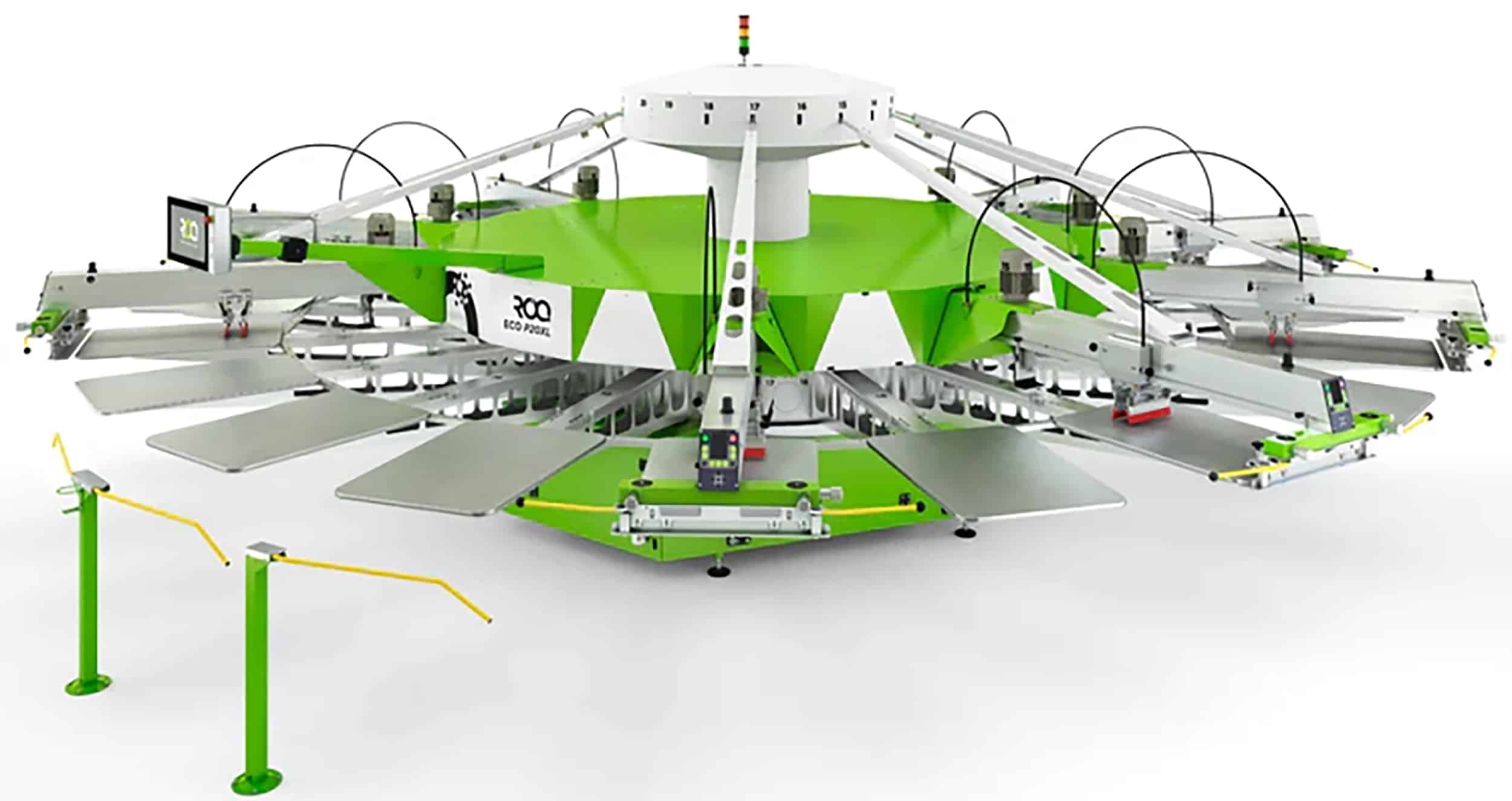

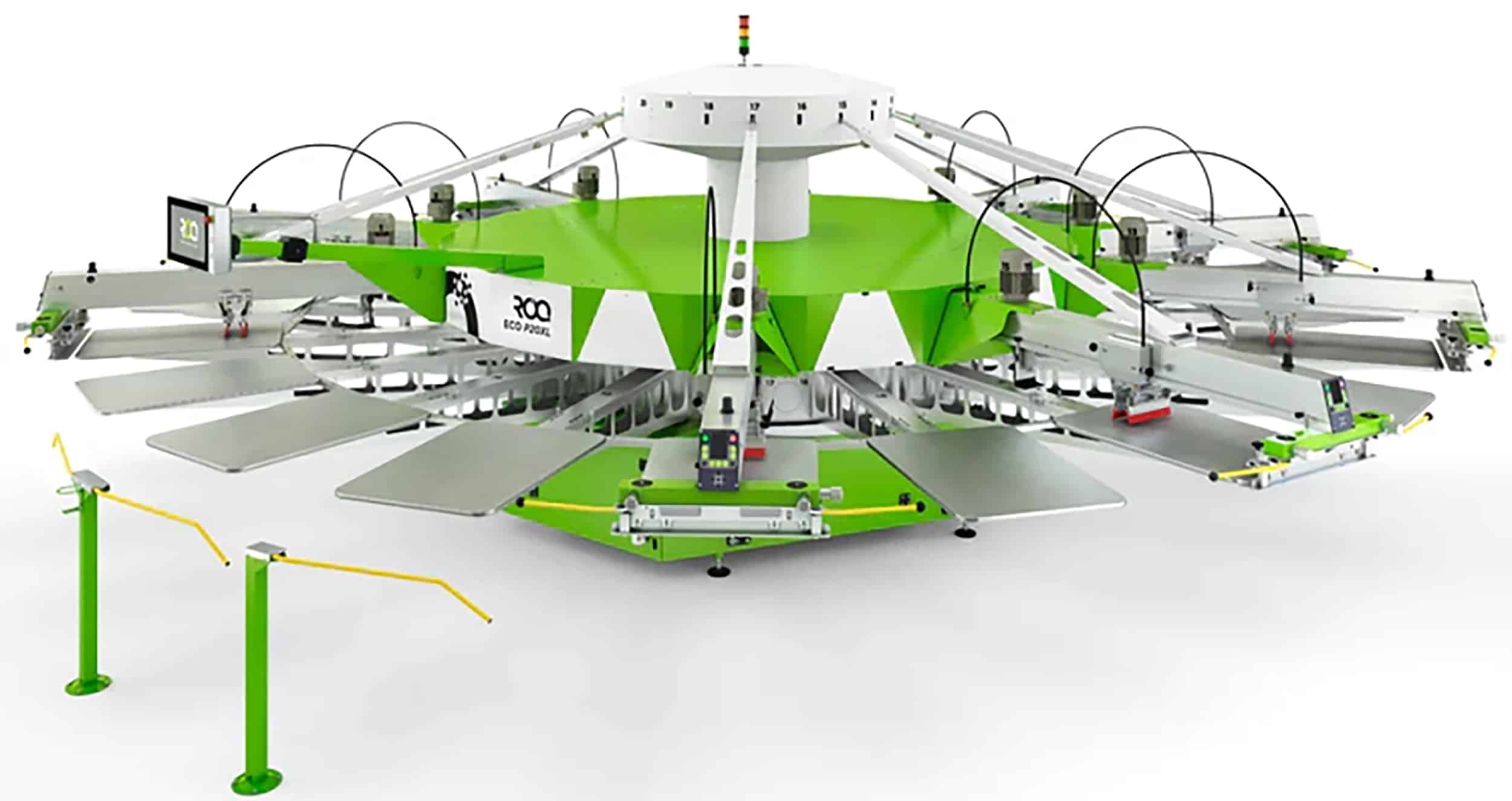

- “ROQ. Besides being solid equipment, their customer service is fantastic, and their community outreach within our industry can’t be matched.” — Alison Banholzer, Wear Your Spirit Warehouse

Nazdar Inks “have saved our butts many times,” says Robert Francis, ScreenPrintPlus.

Nazdar Inks “have saved our butts many times,” says Robert Francis, ScreenPrintPlus.

- Nazdar inks have to be number one. We’ve been using their inks since the early ’60s. (I believe I have a receipt from 1959 for a quart of 5500 series ink.) We started with the solvents then added UV in the mid ’90s. They also have one of the best tech departments. They can answer any questions about inks, substrates, mesh counts, etc. Also, a shout out to American Ultraviolet. We had three of their dryers and they never broke down. — Robert Francis, ScreenPrintPlus

- We’re a huge fan of AS Colour. The Staple T-shirt is great and has heaps of amazing colors. AS Colour has a constantly evolving range, which is great for all aspects of our business. We are also a full M&R shop, with great products. — Shannon McKinnon, Aisle 6ix

- We love our Aeolus Dryer from BBC. Infinitely variable, comes to work every day, does its job, and doesn’t take breaks or check its phone every 10 minutes. The ATMA 120 graphic press we run our flatstock on prints up to 26 x 47 and is designed from the operators’ perspective. Controls are all “up front” and accessible, easy loading and unloading of screens and stock, really accurate, and only whines a bit. Just ran another job and this thing is so accurate and fun to print with. DeFelsko thickness gauge: Starting to really get a handle on screens/stencil thickness and the resultant print result. If only putting out a sharper better print was this easy…. Wait, it is! Fimor Serigraphy squeegee sharpener. Night and day on print quality with a sharp flat squeegee. — Andy MacDougall, MacDougall Screen Printing

- Blanks: Next Level and Bella + Canvas for premium shirts. These have lots of color choices and variety of styles and companion products. They both also have more consistent stock levels and are carried by all distributors, so when sizes are not available at one distributor, others may have it. Mid-price/quality shirts: Port & Company (proprietary SanMar). Fan Favorite and VIP. They usually carry larger sizes and are a step up from the Gildan/Port & Company core. They are also not as “small” as the premium shirts. Downside is they are proprietary and are often out of one size and because no other distributors carry them you have to go with a different brand or sub one size out with another brand. Sweatshirts – Lane Seven, Independent. For more style-driven sweatshirts, lighter weight, and very soft: Bella + Canvas and J. America. Catspit Screen Print Supply Squeegee Rest for the manual printer. I know these are pricey and you can make yourself, but who has time for that? These are sturdy and easy to take on or off, store neatly, and look great at a live print. Keeps your ink coverage to a minimum and makes clean up easier. — Charlie Vetters, Organic Robot Designs

- The double squeegee from Action Engineering is a pretty sweet tool. Especially on long runs and it allows you to only single index the underbase. Also, I really like the Hot Head from M&R. Gives you smooth prints on a hoodie. Such a great tool! M&R has been our brand of machine for 25 years. They make good stuff. The hot head has been the best accessory machine in the last 10 years. Love that thing. — Matthew Pierrot, GetBold – T-shirt Printing and Embroidery

“Favorite blank is Allmade. Good story for a good shirt,” says Ron Goodwin, Goodwin Graphics.

“Favorite blank is Allmade. Good story for a good shirt,” says Ron Goodwin, Goodwin Graphics.

- My favorite piece of equipment when screen printing is the squeegee. The feeling of holding a squeegee is special because it’s the one tool that connects the human to the art being created. My favorite blank T-shirt is Allmade. Being part of the journey when it was being built and manufactured allowed me to see the behind the scenes of big and global supply chains. Plus, it’s a super soft T-shirt and easy to print on. — Gavin StGeorges, seps.io

Advertisement

Top blanks from Jessica Tillery of All Quality Graphics are Allmade, Bella + Canvas, Independent Trading, and District.

- Bella + Canvas 3001/3001CVC have become a customer favorite. “I love the way they feel,” is a common comment. They are great for screen printing and transfers. Stahl’s Ultra Max transfers have changed our lives. They are an incredible sub for multi-color and small run jobs. (Are these considered tools? LOL) Our vintage Hotronix Manual Swinger Heat Press (from the ’90s) still works great. I would love a new one, but this one won’t die!! — Kristin Deutsch, Hair of the Dog Graphics

- Anatol pneumatic printer and exposure unit. Keep them clean and they will work for decades. Anatol screen exposure unit. Easy to program and use, quick and exact, even saturation of light, comes on wheels, works like a dream! — Tracey Johnston-Aldworth, Industry Consultant

- 1. Computer. So much creativity flows in and out of this magical device. 2. Tension meter. Great tension = great printing 3. Smartphone. It’s a recording device that fits in your pocket. Take photos and videos. — Marshall Atkinson, Atkinson Consulting

- Stanley/Stella aligns with our values above other shirt suppliers. They haven’t just introduced new eco-ranges – everything they have made since the beginning is eco so there isn’t the need for greenwashing. We also happen to love using M&R, probably because our main supplier stocks them and we now love using their presses. Both are easy to recommend to new people we are teaching, too. M&R is our equipment supplier and Magna Colours is our inks. Both have great support, great branding, and are trying to stay current with consumer needs and trends, which we are also promoting whenever someone asks what inks or kit we use. — Chessie Rosier-Parker, Squeegee and Ink

M&R, Vastex, Chromaline, Rutland Ink, Inkuin Ink, Shur-Loc Frames & Panels, and Fimor Squeegees are on Charlie Taublieb of Taublieb Consulting’s list.

M&R, Vastex, Chromaline, Rutland Ink, Inkuin Ink, Shur-Loc Frames & Panels, and Fimor Squeegees are on Charlie Taublieb of Taublieb Consulting’s list.

- M&R, ROQ, MHM, Saati, and Kiwo. — Mark Coudray, Coudray Growth Technologies

- Having some success with Supacolor. — Ron Goodwin, Goodwin Graphics

- The Gildan Hammer Tee remains one of my favorites. Great fit and feel and at a great price point! It helps that it’s in stock. — Christine Geronimo, Midnight Supply Company

- M&R presses. Work great, support is very good, resale value is excellent. We can’t get enough of the Sanmar DM130 Tri-Blend. Great shirt, prints well, and our customers love them. — Jim Heiser, Bullseye Activewear

- East West Machine Heat Press. Night Owls sells them now! — Steven Farag, Campus Ink

- East West Machine heat presses. Having solid equipment that just works day after day is such a relief. — Eric Solomon, Night Owls

- Newman Roller Master. This equipment, in conjunction with prefab mesh panels, has revolutionized our screen making capabilities, quality, and efficiency. Encore Engineering Diamond Maxitronic. This 48-inch automated squeegee sharpener is a major upgrade over our first diamond-wheel unit, its manually operated sibling. You can set speed and cycles, adjust the geared advancement, and it has an effective vacuum design to suck up most of the polyurethane dust. Baker Prints custom print carts. We customized Husky’s adjustable-height workbenches to make a fleet of triple-tiered print carts (and a press cart with drawers and make-ready shelf). They make print transport a breeze around the shop, to and from production, and post-press etc. The shelves are designed to keep the heigh-adjustment intact, and this is great for sliding big stacks of prints onto shelves, packing tables, and more. — Kyle Baker, Baker Prints

Advertisement

Expert Perspectives1 week ago

Expert Perspectives1 week ago

Press Releases2 months ago

Press Releases2 months ago

Trends2 months ago

Trends2 months ago

Shop Management1 month ago

Shop Management1 month ago

Shop Management1 week ago

Shop Management1 week ago

Shop Management1 month ago

Shop Management1 month ago

Case Studies1 month ago

Case Studies1 month ago

Tips and How-To1 month ago

Tips and How-To1 month ago

“I like Anatol electric autos, Riley Hopkins manuals, and Union Mixopake Mixing System,” says Eric Courtemanche, Revision Screen Printing.

“I like Anatol electric autos, Riley Hopkins manuals, and Union Mixopake Mixing System,” says Eric Courtemanche, Revision Screen Printing. John Wilhelmsen of Distinct impression says M&R equipment is “easy to repair, and many parts are available locally.”

John Wilhelmsen of Distinct impression says M&R equipment is “easy to repair, and many parts are available locally.”

Nazdar Inks “have saved our butts many times,” says Robert Francis, ScreenPrintPlus.

Nazdar Inks “have saved our butts many times,” says Robert Francis, ScreenPrintPlus. “Favorite blank is Allmade. Good story for a good shirt,” says Ron Goodwin, Goodwin Graphics.

“Favorite blank is Allmade. Good story for a good shirt,” says Ron Goodwin, Goodwin Graphics.

M&R, Vastex, Chromaline, Rutland Ink, Inkuin Ink, Shur-Loc Frames & Panels, and Fimor Squeegees are on Charlie Taublieb of Taublieb Consulting’s list.

M&R, Vastex, Chromaline, Rutland Ink, Inkuin Ink, Shur-Loc Frames & Panels, and Fimor Squeegees are on Charlie Taublieb of Taublieb Consulting’s list.