Graphics Printing

Published

16 years agoon

Do your prints suffer from ink-adhesion problems or surface contamination from dust and particulates? Having issues with media sticking, binding, or misrouting? If so, you may be shocked to learn that your issues are likely rooted in static electricity. Here you’ll learn what static electricity is, how it occurs, and the methods available to counteract it.

What is static electricity?

Do your prints suffer from ink-adhesion problems or surface contamination from dust and particulates? Having issues with media sticking, binding, or misrouting? If so, you may be shocked to learn that your issues are likely rooted in static electricity. Here you’ll learn what static electricity is, how it occurs, and the methods available to counteract it.

What is static electricity?

When a material or object holds a net electrical charge, either positive or negative, it is said to have a static charge. The term static is a relative one, as in many cases static charges will slowly decrease over a period of time. The length of time is dependent on the resistance of the material. For practical purposes the two extremes can be taken as plastics and metal. Plastics generally have very high resistivity. This allows them to maintain static charges for long periods of time; on the other hand, metals have very low resistances and an earthed (grounded) metal object will hold its charge for an imperceptibly short period of time.

Static electricity is usually measured in volts. The voltage present on a material depends on two factors: the amount of charge on the material and the capacitance of the material. The simple relationship is Q = CV, where Q is the charge, V the voltage, and C the capacitance of the material. For a given charge on a material, the lower the capacitance the higher the voltage, and vice versa.

Plastics generally have very low capacitive values and hence a small charge can produce very high voltages. Conversely, metals tend to have high capacitive values and therefore a relatively high charge will produce low voltages. This is why, in practice, problems with static electricity are most noticeable when working with plastic, as it is the voltage level that causes the attraction of dust, operator shock, and misbehavior of materials.

How is static created ?

Three main conditions are responsible for causing static electricity: friction, separation, and induction. The friction of two materials rubbed together causes the electrons associated with the surface atoms on each material come into very close proximity with each other. These surface electrons can move from one material to another. The harder the two materials are pressed together, the greater the exchange of electrons and the higher that charge that is generated. The speed of the rubbing action also has that effect on the level of charge—the faster the rubbing, the higher the level of charge. Surface electrons gain heat energy generated by the friction, and this extra energy allows them to break their atomic bonds and transfer to other atoms.

The method of charging by separation is similar to that of friction. When two materials are in contact, the surface electrons are in close proximity to each other and upon separation have a tendency to adhere to one material or the other. The faster the separation of the materials, the higher the charge generated and, conversely, the slower the separation, the lower the charge.

Factors that affect static electricity

Many factors affect the generation and maintenance of a static charge. Among them are humidity, the type of material, repetition, and change in temperature.

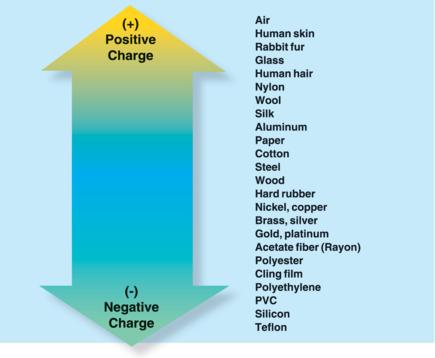

Type of material Some materials are more readily charged than others. For example, materials such as acetate gain a charge very readily, while glass gains a charge less readily. Also the relative position of materials on the triboelectric series (Figure 1) will determine whether a material charges positively or negatively dependent on the other material with which it has come into contact. For example, hard rubber, when rubbed against nylon, will become negatively charged but will become positively charged when rubbed against polyethylene.

Humidity Generally speaking, the dryer the environment, the higher the level of static charge and, conversely, the higher the humidity, the lower the static charge. In relative terms, water is a significantly better conductor of electricity than most plastics. Atmospheric humidity deposits small quantities of water on all surfaces in the environment; therefore, surface static charges on materials have a tendency to dissipate to earth by current flow through the surface moisture.

Repetition Repeated actions, such as friction or separation, increase the level of charge found on a material. For example, a plastic web moving over a series of Teflon rollers will increase its surface charge after every roller.

Battery effect The combination of many charged items can lead to extremely high charges. For instance, individual sheets of plastic with relatively low surface charges when stacked together can generate extremely high voltages.

Change in temperature As a material cools down it has a tendency to generate charge. The action of the cooling is to leave a net charge on the material throughout its entire volume. If the material is a very good insulator the internal (volumetric) static charge can be maintained for extremely long periods of time. However, over time this charge normally migrates to the surface, at which point it becomes a surface static charge. An example of this is an injection molding that is seemingly neutral when hot but can subsequently be found to have a large surface charge once cool.

Common electrostatic problems

The main static-related difficulties printers face include electrostatic attraction, material misbehavior, and operator shocks. Electrostatic attraction (ESA) involves the attraction of airborne particles to charged surfaces—or the attraction of charged airborne particles to surfaces that may be totally free of any charge. This problem affects most plastics-based applications. The ESA effect can attract dust to substrate surfaces and ultimately damage print finishes.

Material misbehavior is another form of ESA. The problem manifests itself in the form of the product itself, usually in the form of material webs, fibers, or sheets sticking to themselves or equipment, misrouting, or repelling inks and coatings. Automated printing processes are particularly prone to this problem.

Operator or personnel shocks are becoming increasingly significant as companies look to improved safety standards. These shocks can be painful, though the effects are usually quite safe and short lived. However, in extreme cases, the debilitating effects can cause personnel collision or entrapment with associated machinery or can even initiate a fire or an explosion in hazardous areas.

Methods of elimination

The fundamental principle for neutralization of static charges is the same, regardless of the technique used. Where a material has a positive surface charge electrons must be delivered to the surface to bring the charge back into balance. Where the surface charge is negative the excess electrons must be removed from the surface to neutralize the charge. The delivery or removal of electrons can be done by one of the these three methods:

• Movement of electrons through the material itself.

• Movement of electrons through another material in contact with the surface.

• Movement of electrons through ioniza tion of the surrounding air.

A fourth method, sparking, occurs when the surface voltage is sufficiently high to cause the air to become conductive. However, the occurrence of sparking is normally due to the lack of application of other methods. More specific approaches to static elimination follow.

Humidity As previously noted, moisture on (or within) a material will tend to leach away static charges down to earth. For example, paper generally has a relatively high moisture content and does not maintain particularly high levels of static. However, if the paper is particularly dry, static can become a severe problem.

Passive ionization The close proximity of a conductor to a charged object will tend to discharge it. For example, a carbon-fiber brush will reduce static charges in materials passed in close proximity to the brush.

Radioactive ionization Radioactive sources cause ionization of the surrounding air, thereby neutralizing surface static charges. A drawback of radioactive eliminators is the radioactive source loses its effectiveness over time and requires replacement on an annual basis.

Active electrical ionization Ionized air can be produced via high-voltage AC or DC, which can then be used to neutralize surface charges. The use of AC or DC systems is application dependent.

Passive eliminators Passive eliminators are useful for reducing high levels of static charge, from tens of kV down to levels of a few kV. However, by their very nature, they are not able to completely neutralize the surface charge. A charged object generates an electric field between itself and any surrounding earthed object (or any object of differing voltage). In the case of a passive eliminator, the field is between the surface and the tips of the carbon-fiber or stainless-steel earthed brush (Figure 2). The fine point at the end of the individual bristles causes the electric field to be highly concentrated at this point. Ionization of the air molecules surrounding the tip occurs when the strength of this electric field reaches a sufficient value. In (Figure 2), the positive charge on the surface of the material causes electrons from the tip of the brush to jump to surrounding air molecules that will then have a net negative charge and are thus negative ions.

Radioactive eliminators Radioactive eliminators employ polonium 210 or other low-level radioactive source. Alpha particles are emitted to the surrounding atmosphere in the process of radioactive decay. These high-speed particles collide with the air molecules and, in doing so, cause the air to become ionized. This ionized air then neutralizes nearby surfaces in similar fashion to the passive eliminators.

AC eliminators AC Eliminators operate at supply frequency. The main voltage (110, 240, etc.) is greatly increased using a ferro-resonating transformer to generate voltages of between 4.5-7 kV. This high voltage is fed to the ionizing pins, and the casing of the bar is connected to earth (Figure 3).

If we look at the positive cycle of the input waveform, we will see that the electrode pin is at a positive voltage compared to the casing. This generates a strong electric field between the two that is highly concentrated at the sharp point of the electrode pin. This, in similar fashion to the passive bar, generates positive ions at the pin point. These mo-lecules are then repelled from the pin due to their like charge. As the ionization at the bar is not dependent upon the surface charge and ions are produced regardless of the proximity of a surface charge, complete neutralization of a surface can be achieved. This is a significant advantage over the passive eliminators.

Pulsed DC eliminators Pulsed DC eliminators, like their AC counterparts, produce ionized air by using high voltage. Whereas the AC units operate at supply frequency the pulsed DC units operate at lower frequencies, often between 0.5-20 Hz. The low frequency of operation lends pulsed DC equipment to long-range neutralization. The ionizing bar consists of a series of emitters connected alternately to the negative and positive outputs (Figure 4). The casing of the bar is made of plastic, so there is no proximity earth.

The output from the power supply is effectively a square wave switching from negative to positive at the chosen frequency. Looking at the positive half of the wave form, the controller switches on the high output voltage connected to the positive emitters. This then sets up an electric field between the emitter and the surrounding earthed objects. At the sharp point of the emitter this field is extreme-ly strong, and in similar fashion to the AC eliminators, positive ions are produced. The similar charge of the ion and the emitter drives the ions away from the bar. Long-range pulsed DC bars can be very effective in screen-printing production by eliminating electrostatic charges from screens without causing drying.

Measurement

Understanding the magnitude—and, in some cases, the polarity—of the charge to be neutralized is a critical part of selecting the proper system for static elimination. In cases where AC eliminators are appropriate, you need to know the magnitude of the static charge so that you can select the correct eliminator bar. In cases where pulsed DC equipment is appropriate, it’s important that you determine the magnitude and the polarity of the static charge in order to correctly set the output’s power and bias.

Measuring the actual amount of surface charge is quite difficult, but you can use a device dedicated to this application to measure the electric field generated by a statically charged object, the unit of which is volts per meter. Measuring the field at a known distance enables you to deduce the surface voltage.

How much do you charge?

Evaluating the causes of static electricity in your shop is the first step to gaining control over the situation. Take a look at the ways in which your equipment runs and how your staff handles substrates. Monitor the environmental conditions in the workspace, keeping a close eye on temperature and humidity. From there, you can determine how much of a charge you generate. Finally, working with a specialist who can use the data you’ve collected and assist you in your efforts will ensure that you implement dynamic solutions to your static problems. n

Glossary of Electrostatics Terminology

Capacitance: A measure of the ability of a substance to hold charge.

Coulomb: The unit of measure of electrical charge.

Conductance: The higher the conductance of a material the easier charge will flow through it. Metals are very conductive.

Electron: A small atomic particle with a negative charge (1.6 x 1019 coulombs).

Ion: A molecule or atom with an electrical imbalance (a negative ion has an excess of electrons, a positive ion has a deficit of electrons).

Resistance: The higher the resistance of a material the harder it is for charge to flow through it. Insulators such as plastics are very resistive.

David Rogers is international product manager for Meech Static Eliminators. He’s been with the company for the past 13 years and was appointed to his current position this year. Rogers previously worked for Meech in technical sales support, and he continues to use his applications expertise and product knowledge to increase productivity and profitability in industries such as printing, plastics, converting, and packaging.

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?