THE WORLD OF FUNCTIONAL and industrial (F&I) printing is hiding around us in plain sight. Since first appearing in the 1940’s, F&I has managed to avoid the U.S. and Canadian governments, who still consider print as predominately on paper. The average person wouldn’t know about F&I printing and, I have to say it, the average T-shirt or poster printer is blind to it as well. That’s even though we collectively use the products that rely on this category of printing in their manufacturing process hundreds and thousands of times every day. You’re reading this on a device full of print.

Dan Gilsdorf, VP Sales — Screen Printing at Sefar USA. Listen to our interview on the podcast.

Our guest on Podcast #20, Daniel Gilsdorf is VP of Screen products at Sefar US, one of the world’s oldest and largest providers of woven materials used on everything from sport stadium roofs to industrial filtration systems. And, of course, screen-printing meshes!

What makes Sefar a bit different, and the reason we are lucky to talk to Mr. Gilsdorf, is its high-end screen making and related technical services in various locations arounds the world. It’s where they create finished screens for some of the world’s largest companies engaged in F&I printing. Stainless steel at 730 threads per inch? Stencil resolution with 20 micron details? Output up to 50,000 dpi? This ain’t yer’ average T-shirt shop.

Without naming names and giving away industrial secrets, he helps us understand this market. The size of it. The areas of growth. The shifts in manufacturing technologies, locations, and current and future needs. Interestingly, a lot of new business comes from smaller start-ups, exploring the outer limits of things we can make with our squeegees. Electronic. Biomedical. Sensors. Energy devices.

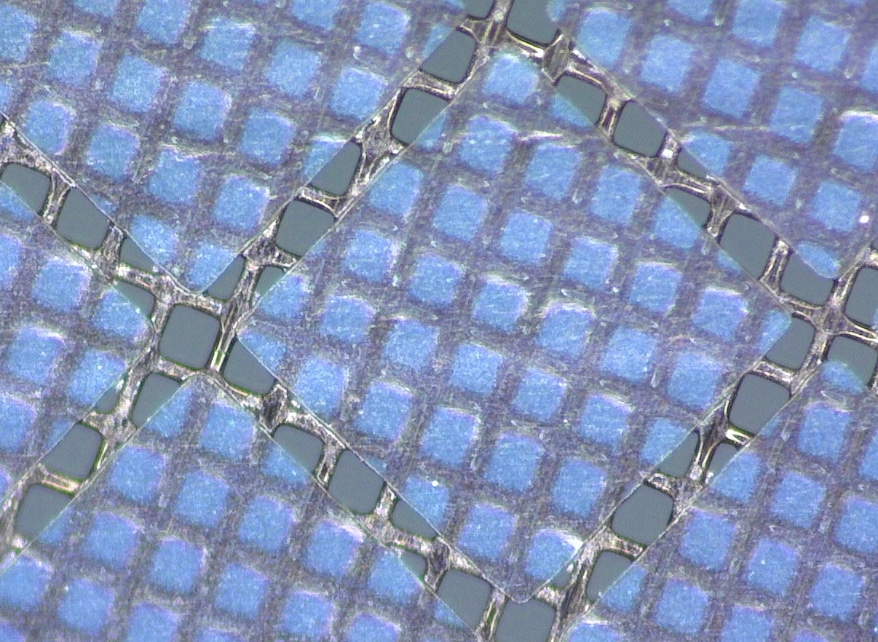

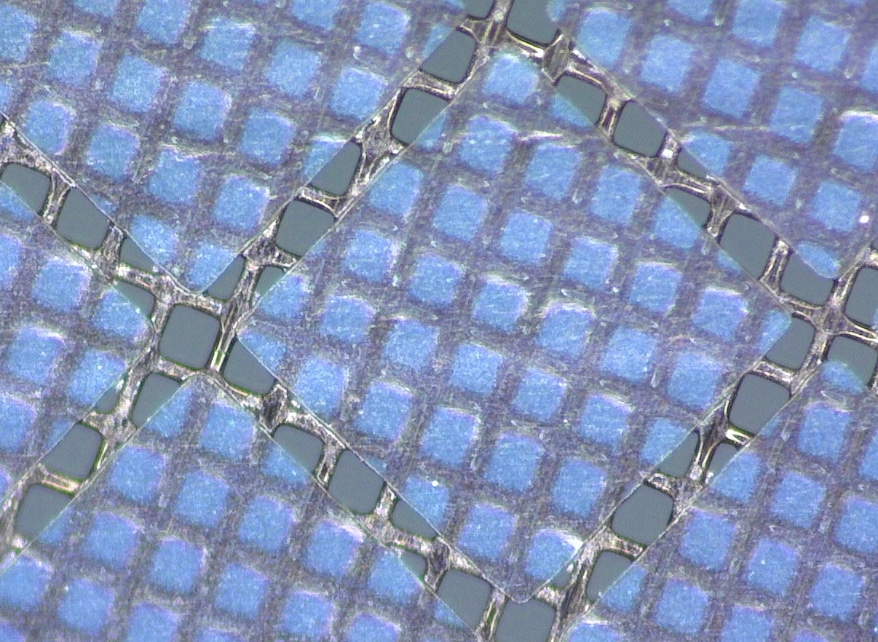

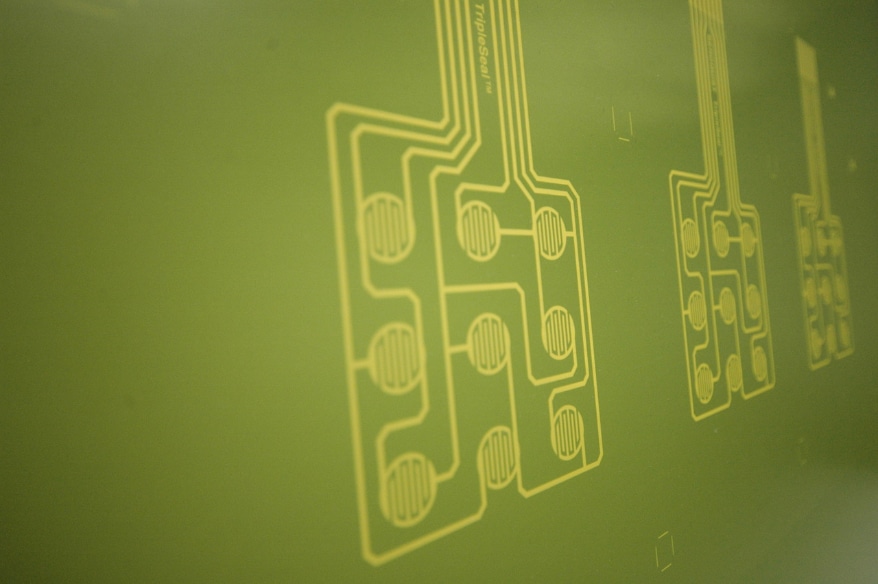

This shows a stainless-steel calendared mesh count 500, with stencil openings of 20 microns. For reference, a human hair is around 70 microns. Photo courtesy SefarGilsdorf

A Quiet Industry

The government, the education system, even our beloved Printing United Alliance see screen printing and the products we make as things like, “A sunset industry,” “A dying art,” or “Analog.” It is ironic that the modern digital world runs because of screen printing and the hardware made using it. And it’s also sad that such a specialized application of the process, invented in North America, ends up perfected overseas with the knowledge and skills residing there, and lost here over the past 20 years.

But the tide is changing as more manufacturers are returning, or at least shifting, some production onshore. And plant engineers are wondering about this “silk screening” thing they need to set up. Not exactly something you can learn from a YouTube or a TikTok influencer.

Screen printing remains the manufacturing process of choice in many markets and diverse applications within this functional print world. Not digital. Not offset or flexo. They try, but they can’t produce the trifecta that screen printing does so very well such as:

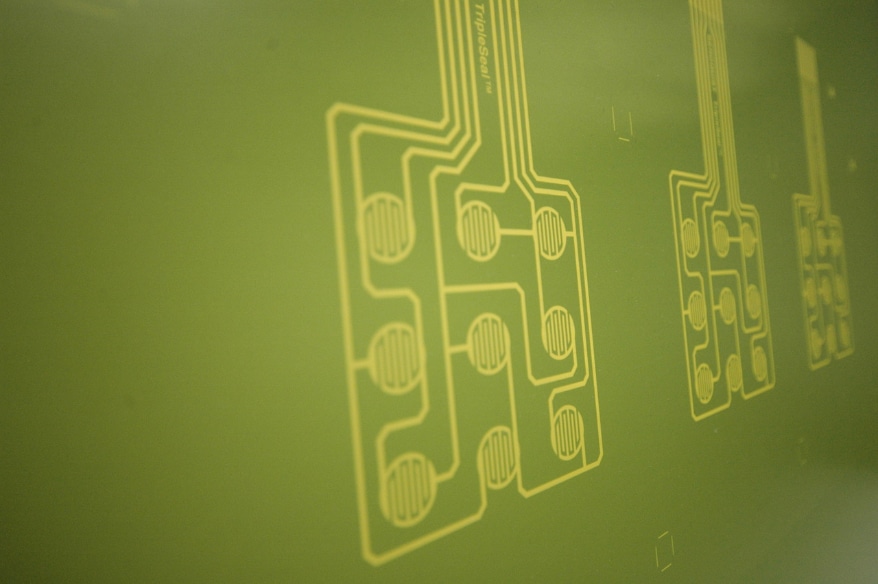

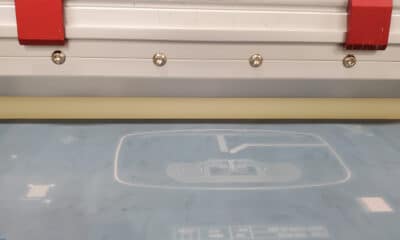

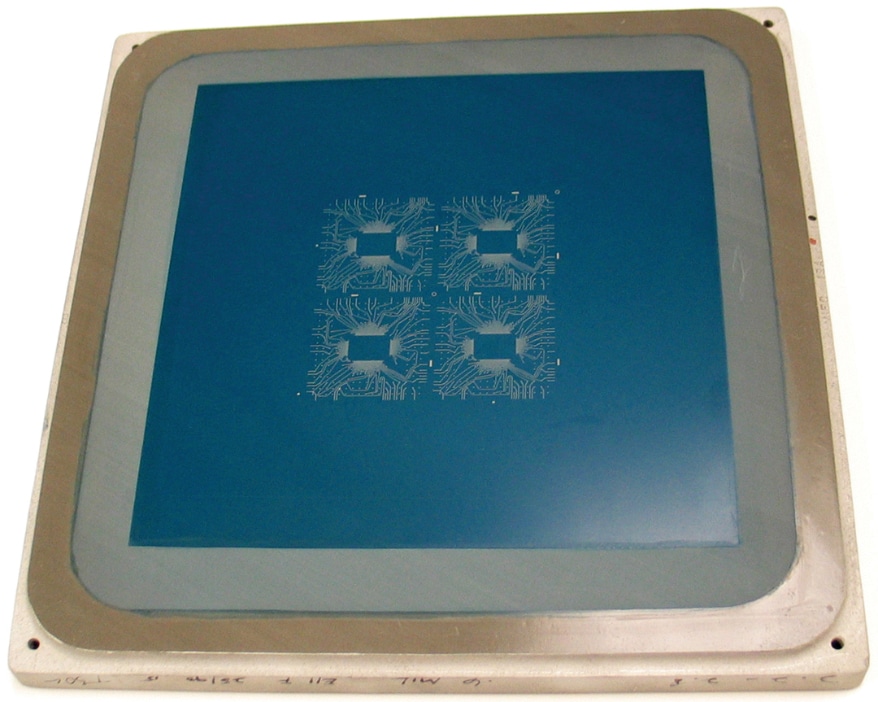

A closeup of a stencil for printing circuits. Advancements in technology keep pushing screen printing and screen making into finer and finer detail. Photo courtesy Sefar

- Lay down exotic materials formulated into pastes or inks in detailed patterns or coatings.

- Do it with a controlled, measurable, and repeatable deposit of varying thickness.

- Print onto a wide range of substrates and objects, regardless of material type, shape, thickness, or size.

Oh, and we can do it quickly. Simply. Economically. Durably. Screen printing checks a lot of boxes.

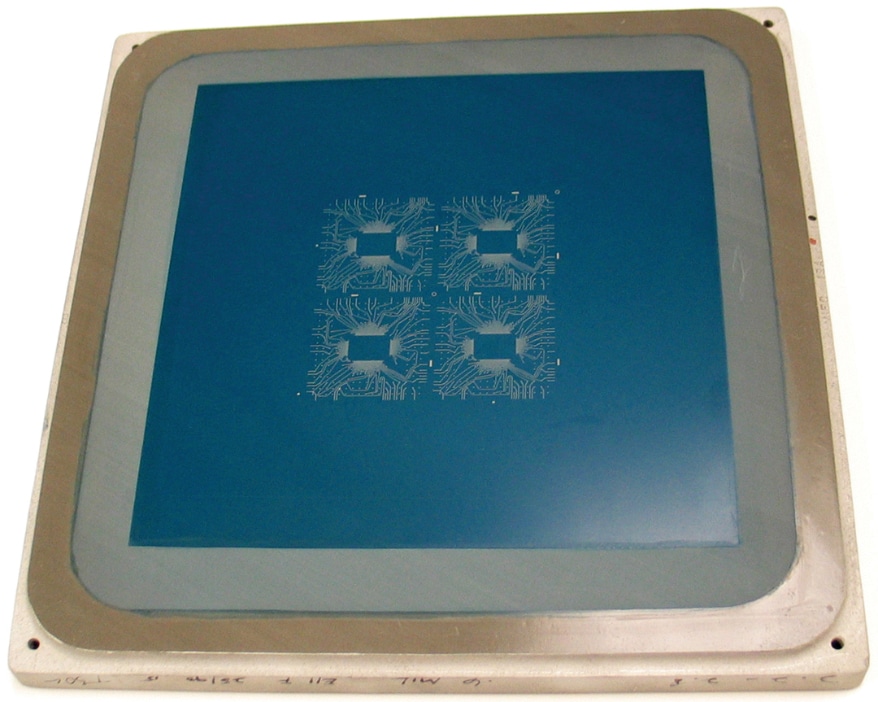

Here’s another fine-detail screen. In less than 10 years, line widths for conductive pastes have shrunk by half.

How big is this market? Massive. And growing. Imagine we stack up every cell phone and tablet ever made. Next, all of your consumer electronics and appliances. Then we throw every car windshield on the pile. Dashboards and touchscreens. And we add all the solar cells. Include hydrogen fuel cells and let’s scrape the inside of every Boeing airliner. The wallpaper technically is graphic screen printing, but its function is fire-resistance. Next, we dump on all the Covid rapid tests, diabetic test strips, and a bunch of nicotine patches. Pretty big pile? We’re only getting started.

In the Podcast, Dan lifts the curtain and gives us a peek into the F&I print world. One of the main reasons it is hidden is because a lot of the printing techniques and processes, custom equipment, and end use is proprietary, developed, and used in-house. The other is that most manufacturing of consumer goods — and their electronic components — moved offshore as the Walmarts of the world became retail outlets for the C.H. Ina Corp. So the skills to make things “locally” became scarce too.

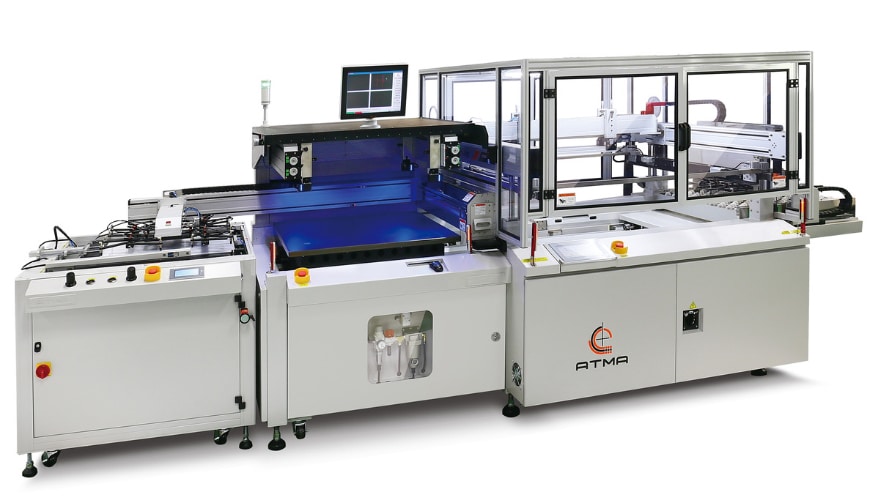

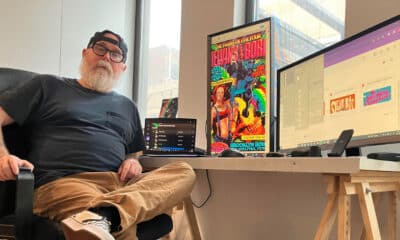

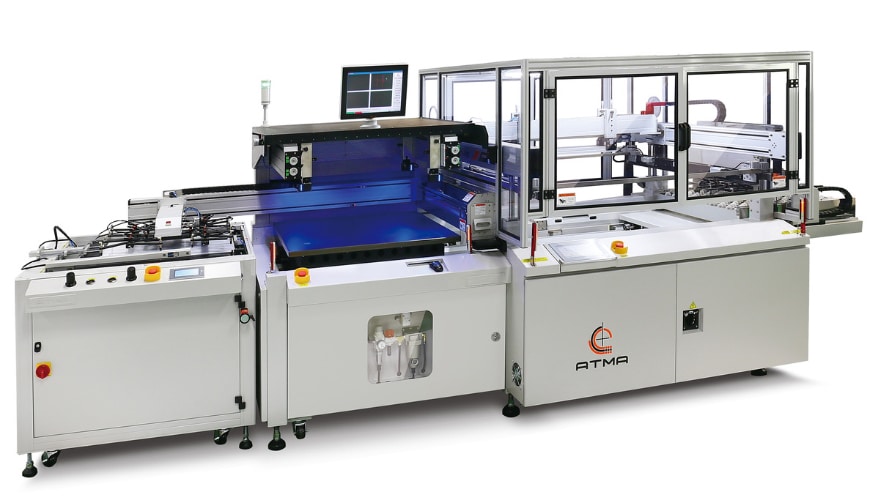

This press is used for critical registration printing. It features a feeder that uses CCTV to bring the part into perfect registration before printing. An automated take-off moves the printed piece onto a dryer. Photo courtesy RH SolutionsSEFAR

What’s F&I Really?

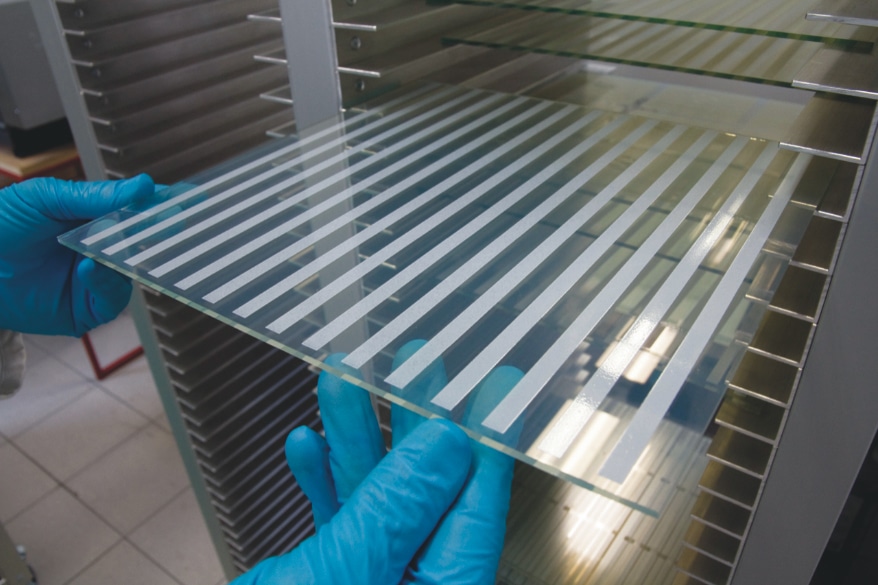

Gilsdorf defines functional and a large part of industrial printing as anything that’s not graphic, or an image, and where it does something. F&I uses the screen process to deposit specialized materials onto other components. Flexible, lightweight circuits are created by printing conductive inks on successive layers of other materials — insulating layers, then more circuits. That’s why phones and electronics and control interfaces shrunk so rapidly in the 90’s and into the 2000’s. Wires and hard electronic circuit boards were replaced by flexible printing. Solar cell manufacturing was exploding in the U.S. until 2016, when an ill-considered ruling backfired and put a tariff on domestic cell production. Whoops. But Dan says it’s back, as green energy grows.

Gaskets on industrial parts are another example. I’m not only talking for motors but for creating components within hydrogen fuel cells. A crossover (with graphics) might be printing parts or objects such as your favorite brewpub’s logo on growlers and glasses, for example. Actually, there’s a lot of glass in F&I printing. Every windshield in every car? Sure. That black pattern around the edge? That’s industrial screen printing. Print an aerial or sensor and it’s now functional.

In the podcast, we learn that Dan grew up in St. Paul, Minn., and came into the SPU by lucking into a job in a shop that had him screen printing all the weird stuff that wouldn’t work in an offset press. Ad specialties, fixtures, displays….it was something different for nearly every job. He learned about matching inks to materials, and how to make jigs to hold parts. He worked this job through college, where he studied industrial technology and graphic arts management. When he asked about screen printing, an instructor told him to get into offset. Pfffft.

Using the knowledge from his job, he organized the printing club at the university and had them making T-shirts for bars, clubs, and events, until a local business complained. He ended up back teaching screen printing at the school while working at 3M where he helped set up CD, DVD, and optical disc screen printing in Wisconsin, California, and the Netherlands. It was replacing pad printing and growing at 10 times each year for five years running as that market took off. He’s been with Sefar since the 1990’s.

Sitting in the car, or even a quick look around your kitchen, shows us numerous examples of industrial and functional printing. From the labels on the car dashboard, or your coffee maker and carafe and stove top, screen printing is used because it works on dimensional products, adapts to hard to print surfaces, and is durable.

But all screen printing all the time makes Jack and Dan a dull boy. In an ongoing Triple A segment I like to call, “Scratch the Screen Printer, Find the Musician,” we learn that Gilsdorf is a bit of a guitar nut. He recounts the story of his discovery of Norman’s Rare Guitars in Los Angeles, and Michael Lemmo’s “Guitar of the Day.” Check it out here. Dan calls it a life-changing experience instigated by an encounter at a screen-printing trade show.

It’s telling that when I asked Dan to name off 10 F&I things made using screen printing that people might not know about, the first four were music related: Headstock logos, guitar pics, guitar effects pedals, and mixing board labelling. He followed those up with glass stovetop elements, watch faces, measuring cups, cow ear tags, beer kegs, and night vision goggles.

Like I said in the beginning; F&I printing is hiding in plain sight. The next time you use your phone, thank the screen printers that make it function.

Advertisement

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Columns3 weeks ago

Columns3 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Case Studies3 weeks ago

Case Studies3 weeks ago

News & Trends2 months ago

News & Trends2 months ago