Prepress & Screen Making

Published

23 years agoon

If I were a newcomer to screen printing and began looking at the catalogs from various mesh manufacturers, I would probably feel like turning to another profession. Faced with a selection of more than 200 different mesh types and counts, I would be compelled to find a way to narrow the field. Of course, after I learned the basics of the process, I would be able to quickly select the right type of screen fabric, because multifilament fabrics are things of the past and nylon is not stable enough for close tolerance printing. I might also know that high-modulus fabrics are the current trend.

If I were a newcomer to screen printing and began looking at the catalogs from various mesh manufacturers, I would probably feel like turning to another profession. Faced with a selection of more than 200 different mesh types and counts, I would be compelled to find a way to narrow the field. Of course, after I learned the basics of the process, I would be able to quickly select the right type of screen fabric, because multifilament fabrics are things of the past and nylon is not stable enough for close tolerance printing. I might also know that high-modulus fabrics are the current trend. This would narrow down the selection considerably, but I would still be faced with a catalog of about 50 products, in various weaves, mesh counts, and thread diameters. The task of choosing the right mesh would still be too big for a beginner like me. In reality, do we really need so many mesh counts? This is an important question, and I sometimes wonder whether mesh manufacturers–ourselves included–aren’t masochistic to be producing so many mesh varieties. We will explore the answer to this question and analyze the possibility of rationalizing the vast number of screen fabrics to what is really necessary. Throughout this discussion, we’ll focus our attention on fine meshes and their tonal reproduction capabilities with UV ink systems. Why are there so many grades of mesh? Blame the versatility of the screen-printing process. In the days of silk and multifilament screen fabrics, the limited availability of different thread diameters kept the range restricted. The screen process was, however, quickly recognized for its versatility, and, as the increasing number of applications became more demanding, there arose a need for higher-performance fabrics. Monofilament yarns were greeted with open arms because they enhanced the capabilities of the screen-printing process. As ink manufacturers developed new products that addressed the needs of the market, mesh manufacturers followed suit, making fabrics that optimized the performance of the new inks. While screen printing grew into a viable commercial and industrial manufacturing process, product specialties, and the fabrics used to print them began to vary from country to country. One country might specialize in industrial textile printing. Poster printing would be dominant in another. And within specific types of printing, different countries would adopt their own "standard" grades of screen fabrics. So, on one side of an ocean, mesh count X became the standard for a particular job, while on the other side, mesh count Y was being used for exactly the same application. Mesh manufacturers continued to produce an increasing range of products to satisfy their global markets. Yarn manufacturers began extruding finer threads and weavers became more daring, weaving mesh counts that would have been unthinkable 20 years ago. The development of new screen fabrics contributed to the growth of the role of screen printing in so many industries. And today, the screen printer is spoiled for choice.

| Table 1 Comparison of Fine Mesh Characteristics | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mesh count (per inch) |

Nominal thread diameter (microns) |

Weave type | % Open area | Fabric thickness (microns) |

Theoretical ink volume (cm3 / m2) |

355 | 27 | PW | 36 | 42 | 15 | 355 | 31 | PW | 28 | 47 | 13 | 355 | 34 | TW | 20 | 60 | 12 | 355 | 34 | PW | 16 | 58 | 9 | 390 | 27 | PW | 27 | 44 | 12 | 390 | 31 | PW | 20 | 49 | 10 | 390 | 34 | TW | 17 | 63 | 11 | 390 | 34 | PW | 13 | 56 | 7 | 420 | 27 | PW | 25 | 46 | 12 | 420 | 31 | TW | 24 | 60 | 14 | 420 | 31 | PW | 17 | 49 | 8 | 420 | 34 | TW | 16 | 62 | 10 | 460 | 27 | PW | 18 | 43 | 7.5 | 460 | 31 | TW | 17 | 56 | 9.5 | 508 | 31 | TW | 13 | 65 | 8.5 |

Mesh selection varies with the application For many graphics screen-printing applications, mesh selection is entirely influenced by technical circumstances. Ceramic tile decorators, for example, depend on an extensive selection of fabrics to create special, value-added effects. The various mesh counts and mesh openings regulate the deposit of glazes on the surface of the tiles to create embossed effects or refined third-firing decoration with the deposit of precious substances. Generally speaking, coarse meshes are used more as ink-flow regulators than for design quality. Industrial textile printing, for example, requires its own mesh specifications to enhance the printing of inks containing refined pigments or dyes. And some inks for glass printing contain glass particles of various sizes, requiring yet a different set of mesh specifications. We can accept some applications’ technical requirements for specific types of mesh. For the time being, however, we will concentrate on mesh selection for general graphics and P-O-P screen printing, which still accounts for a large segment of all screen-printing applications. For this segment, a great majority of the mesh counts purchased today are superfluous; a broad range of printing applications could be done with an inventory of no more than two or three mesh counts. In achieving a standard of rationalization, you can avoid waste and confusion, and in the long-term, save money.

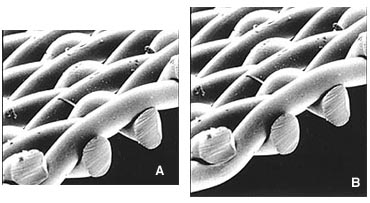

In most cases, the two main factors to consider when selecting a screen fabric are the ink system and the artwork. The screen fabric is a necessary evil–necessary because it supports the stencil, and evil because it may well obstruct the passage of ink during printing. The correct mesh count must properly support the finest stencil details while maintaining the perfect stencil profile for the job. And to faithfully reproduce the image, the ink must be able to flow through the fabric openings. Ink flow is particularly important in halftone printing. The mesh must help to maintain the correct balance throughout the desired tonal range. It is common for shadow dots to be blocked by mesh fibers, changing the tonality of the print, losing detail, and altering overall contrast. Of course, we mustn’t consider mesh alone. Its selection may be correct for a job, and the print may still be unsuitable. It is also important to examine closely-linked parameters, such as artwork factors, screen tension, stencil quality, and press setup. In selecting a mesh, one has to consider the type of ink being used. UV-curable and solvent-based inks place different demands on the mesh. With UV inks, deposit becomes virtually the only factor to consider, and, in some ways, makes the task of mesh selection easier. The selection of fabrics for printing with solvent-based inks was, for a long time, the main topic of discussion. But the growth of four-color-process and UV-printing has led to an increasing number of fine mesh counts, and these trends will be our focus. Defining the fine-mesh concept If a simple technical expression like "fine mesh" is meant to differentiate between a fabric designed for printing glitter inks and one used for fine detail, then it is clear what we are talking about. In other words, a 46-thread/in. mesh is defined as coarse and a 355-thread/in. mesh is obviously fine. Most of the time we speak of fine meshes as a group of fabrics that produce the lowest ink deposit; the higher the thread count, the lower the deposit. And by the same token, we often believe that the higher thread counts make for more fragile fabrics. Putting these two thoughts together, we come to believe that the finest meshes deposit the least amount of ink, but with a tradeoff in fabric strength. This is not necessarily the case. Let’s try to put a bit of order to this way of thinking. Of all the screen-printing components, the screen fabric is the greatest regulator as far as ink consumption or ink-film thickness are concerned. Broadly speaking, the ink volume will be directly influenced by the fabric thickness and open area of the mesh. Logically, both factors depend on the density of threads within a specific area. You can use one of several formulas to calculate the percent open area and total open area in a given area of mesh. Figures may also be obtained from mesh manufacturers, who offer them based on metric calculations of loose fabric. Of course, the distance between two adjacent threads will vary in fabrics woven from different thread diameters. Today, a single mesh count can be produced with up to three or more different thread diameters, which makes a big difference in the percentage of open area. Another factor that must be considered is the weaving structure of the mesh. Any single mesh count can be produced in either plain or twill weave. The type of weave influences the fabric thickness, even though the nominal mesh count and diameter remain unchanged. You can see a noticeable difference between a plain-weave (PW) fabric (Figure 1A) and a twill-weave (TW) mesh (Figure 1B). The bridging of the two threads in the twill type contributes to the increase in fabric thickness. It also demonstrates how much more compact the plain weave mesh is, which contributes to the reduction in the amount of open area. This means that a twill fabric, which is thicker and has more open area, will deposit more ink than a plain weave fabric of the same mesh count and thread diameter. A simplified calculation of theoretical ink volume is obtained by multiplying the fabric thickness by the percentage of open area. This calculation takes all previously mentioned mesh specifications into account and is expressed in cubic centimeters per square meter. (The metric system is the original system used for mesh calculations and remains the standard.) Table 1 lists data for 15 different fine meshes that might typically be used in UV graphics printing applications. Looking at the "theoretical ink volume" column, we can observe vast differences between the "fine" meshes in the table. For printing UV ink, it’s necessary to select a mesh that offers a low theoretical ink volume, particularly when printing process-color work. Of course, it is also very important to look at the balance and completeness of the tonal range of the halftone print. On the stencil, highlight dots require mesh openings large enough to allow the passage of the ink; shadow dots can literally fall through mesh openings that are too large. So a compromise has to be found.

Diagrams A-K chart the printable tonal ranges, based on practical printing tests. The fabrics used in these tests were orange monofilament polyester. All stencils were judged to be of optimum Rz and thickness relative to each mesh. They were exposed with a 5K metal-halide lamp at 48 in. The halftone artwork consisted of elliptical dots, and the art was positioned at 37

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Case Studies3 weeks ago

Case Studies3 weeks agoScreen Printing for Texture and Depth