With the increasing demand for quick turnaround on production runs of point-of-purchase and point-of-sale graphics, print shops are looking for ways to accommodate such requests from existing clients and attract new customers—all the while keeping efficiency, production costs, and other related considerations under control. HP Scitex says it now offers a solution designed to allow screen printers to implement digital imaging technology at a reasonable investment, enjoy high production on an array of rigid and flexible media with a system that uses less power and floor space than screen presses, and reduce their impact on the environment with the use of UV inks.

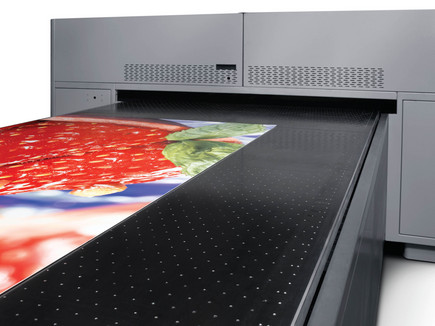

The HP Scitex FB7500 is a wide-format flatbed UV inkjet printer intended for signage, exhibition graphics, backlit displays, bus shelters, and posters. It accepts a variety of rigid and flexible media up to 1 in. (25 mm) thick. The printer is equipped with 312 HP Scitex X2 drop-on-demand piezoelectric inkjet printheads (52 per color), based on microelectromechanical (MEMS) technology, that operate on a 20-kHz firing frequency through 39,936 nozzles, which HP Scitex says produces the ink flow required to print high-quality images at high speeds ran-ging from 1500 sq ft/hr (140 sq m/hr) in Best Quality mode up to 5380 sq ft/hr (500 sq m/hr) in Express mode. It supports imaging resolutions up to 500 dpi (native) and accommodates media up to 65 x 126 in. (1650 x 3200 mm).

HP Scitex FB220 UV inks, developed specifically for the HP Scitex FB7500 Printer, are formulated to cure quickly and offer two years of outdoor durability, as well as resistance to water and abrasion. The inks are available in six colors (CMYKLcLm) and reportedly deliver a very wide color gamut with offset-like vibrancy, sharp text, and smooth color transitions without graininess or artifacts.

The printer uses a 3⁄4-semiautomatic material workflow, designed to reduce idle time between sheets by up to 85% with only one operator. The machine is equipped with a loading mechanism that’s engineered to provide the productivity and versatility required by large-format screen-printing and offset-printing operations. Once the user inserts a sheet between a set of inline media sensors, the loading system is activated, which initiates the automatic alignment and registration process. A substrate-thickness indicator automatically verifies media thickness.

The printer’s vacuum table features six zones and moves efficiently according to the media’s length. Once the sheet is printed, it is unloaded automatically to the lift, while the next sheet is simultaneously placed on the vacuum table. Manual mode is available for printing one-off jobs, utility files, and jobs on sensitive media.

The printer is compatible with a variety of substrates, including foam PVC, PVC sheets, foamboard, corrugated cardboard, display board/cardstock, compressed cardboard, polystyrene, SAV, paper, synthetic paper, banner material, corrugated polypropylene, polycarbonate, and more. The FB7500 comes with Onyx I-RIP Plus and supports commonly used file formats such as PostScript, EPS, TIFF, PSD, PDF, and JPG. For more information, contact Hewlett-Packard Co., 3000 Hanover St., Palo Alto, CA 94304-1185, 650-857-1501, fax: 650-857-5518, Web: www.hp.com.

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns3 weeks ago

Columns3 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

News & Trends2 months ago

News & Trends2 months ago