Digital Printing

Published

18 years agoon

Ifyou’re involved in digital printing, getting a design file from your computer onto paper, film, or whatever substrate you’re working with may seem pretty simple and straightforward. But when you hit “print” to start a digital-imaging device, a lot of things begin happening. The images on your screen aren’t just copied by a digital printer because, among other things, screen images have a resolution of 72 dpi, while digital-output systems provide resolutions of 300-2540 dpi or more. Digital files must be converted for output to a high-resolution printing device, and the brain behind this conversion process is a raster image processor (RIP).

Like most printing processes, a RIP creates dots. At 2540 dpi you can’t see these dots without magnification, but they are there. It’s the RIP’s job to see that each and every dot is rendered at the right size and deposited in the right place by the printer. With today’s print workflows and wide variety of input and output devices, RIPs have become significantly more complex and capable.

These days there are literally hundreds of RIP products. Some are software based and use your own computer as the hardware for doing all the data crunching. Others are sold with hardware and software. This type of configuration allows your computer to continue to work on other things while the RIP does the printing. In this overview, you’ll learn about both types of RIPs and get advice to help you determine which products can best meet your file-processing needs.

The evolution of RIPs

Before RIPs, there were computer typesetters, which were made to do only one thing: set type. They weren’t even digital, but used an analog photographic process to produce film for platemaking. A type font was a spinning piece of photographic film negative used to expose photographic paper. The computer was used to control when the exposure was made. If you wanted to change the font, you had to pull out the film and put in a new strip. It took minimal horsepower to drive such a device, but the slow speed of these early machines would be considered unendurable by today’s standards.

Even when Adobe first introduced PostScript, allowing computers to combine text, illustrations, and photographs, RIPs were fairly simple things. The first laser printers were black and white, and 300 dpi was considered high resolution. This was a good thing, because computers of that era were still painfully slow. But RIP technology didn’t stay simple for long. As computers got faster and desktop publishing software got more sophisticated, much higher demands were put on the software that created the file that a laser printer would actually print. Color was introduced, which put a further strain on processing time.

Today, a typical high-resolution four-color image contains about 40 MB of data. Such a file would have choked the early RIPs and taken considerable time to produce. In the early days of PostScript output, 20 min/page was considered very fast in a production environment. But now RIPs are producing closer to 20 pages an hour, and some are even faster. A high-end production RIP might produce 20 pages in about 10 minutes. And the technology will only get faster. With today’s processor speeds, RAM specifications, and disk-drive space and speed, RIP speed is no longer a major concern, and you can find a RIP that is fast without difficulty.

What’s in the box?

Many printer manufacturers and resellers offer more than one RIP with their products, but often the printer package is sold on the basis of price rather than capabilities. A few printer manufacturers, such as Roland, Canon, and Mimaki, offer only their own RIP, which may be fine for many users. Of course that does not mean that a third-party RIP will not work with these machines. All of the printer manufacturers work with third-party RIP developers to provide drivers for their machines.

What comes in the box may not be what you need in your specific workflow, and there are many things to consider when choosing the right RIP for the work that you do. Indeed, the front end used to run your printer may be as important as the printing device itself. Figuring out how various printers can be run most efficiently and effectively demands a hard look at how they are driven up front, particularly if you want to be able to use one RIP to run multiple output devices.

RIPs are no longer simply number-crunching tools. They are also file-management tools, color-management tools, and sometimes much more. This means you have a lot of factors to consider when choosing among RIPs. Here is a list of the some of the primary points to weigh:

Software RIP vs. hardware RIP This consideration relates to where file processing takes place and how much time you can afford to keep your production computer tied up. Software RIPs are designed to work on a client machine. This option has the advantage of being less expensive initially, but it may have the disadvantage of tying up your production computer or forcing you to buy another computer to dedicate to image processing. With a hardware RIP, you are actually buying another computer with the RIP software. Hardware RIPs are generally optimized to maximize file-processing and transmission speeds, but these capabilities come with a higher price tag.

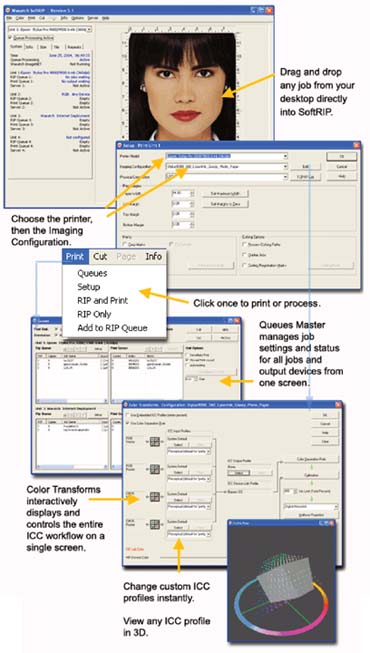

Color handling The color needs you have really depend on your workflow and the printing methods you employ. Color-management tools help you maintain consistent, accurate color. RIPs that support ICC profiles allow you to match output from one printing device to another (Figure 1). Pantone color libraries are valuable because they allow you to get the closest possible match to Pantone color swatches. Many RIPs also allow you to manage spot colors differently from process colors, which means you can take advantage of the higher color gamut of today’s six- and eight-color inkjet printers.

Image imposition Many screen printers and other wide-format inkjet users like to be able to step and repeat images or impose image files. Some RIPs include imposition features. Of course, the more sophisticated the capabilities, the more you are likely to pay, so it’s important to determine whether you really need those capabilities. Many RIPs are modular, so you can add such capabilities as you need them. If you print packaging, you may want to pay a premium for an imposition package that allows custom tiling and nesting.

Productivity Some printers don’t consider the efficiency of their workflow when they buy a RIP; instead, they simply buy what comes with the printer. The problem is that some RIPs are designed specifically to operate only one printing device, while others will output to dozens or even hundreds of different devices and may accept print drivers to run even more machines.

A RIP-once-output-many (ROOM) device is the ultimate in production efficiency. ROOM capability means the RIP can send the same finished file to any number of different printing devices without having to process the file again. In addition, many RIPs will allow you to simultaneously output to multiple devices.

Workflow controls Closely linked to productivity is the amount of workflow control RIPs give to users. It’s hard to find a RIP these days that does not have some sort of workflow-automation enhancements. These enhancements could be hot folders for queuing and previewing jobs prior to final output (it’s always cheaper to find a problem before it hits the paper) and Web interfaces so all of the operators, and even customers, can track the status of jobs in progress.

File-format support At the very least, a RIP should provide PostScript Level 3 support and native PDF support. TIFF, EPS, and JPEG are also commonly supported formats.

An emerging format that you may also want the RIP to support is the job definition file (JDF) format. The JDF format brings vital job information along with the job, and JDF-compliant RIPs can actually control file output based on these electronic tags without operator intervention.

JDF support is still not widely available, but most RIP developers are working to incorporate it in their products. It might be worth considering if you can use it to streamline your operation. In addition, if you are outputting to a wide variety of devices, you may need 1-bit TIFF output capabilities.

For many years, most RIPs were designed to run on Windows platforms. But today, more and more are also porting to Mac OSX, and a few will run under Linux.

What’s the difference?

There can be a wide price variance in RIPs

Subscribe

Magazine

Get the most important news

and business ideas from Screenprinting Magazine.

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Case Studies3 weeks ago

Case Studies3 weeks agoScreen Printing for Texture and Depth