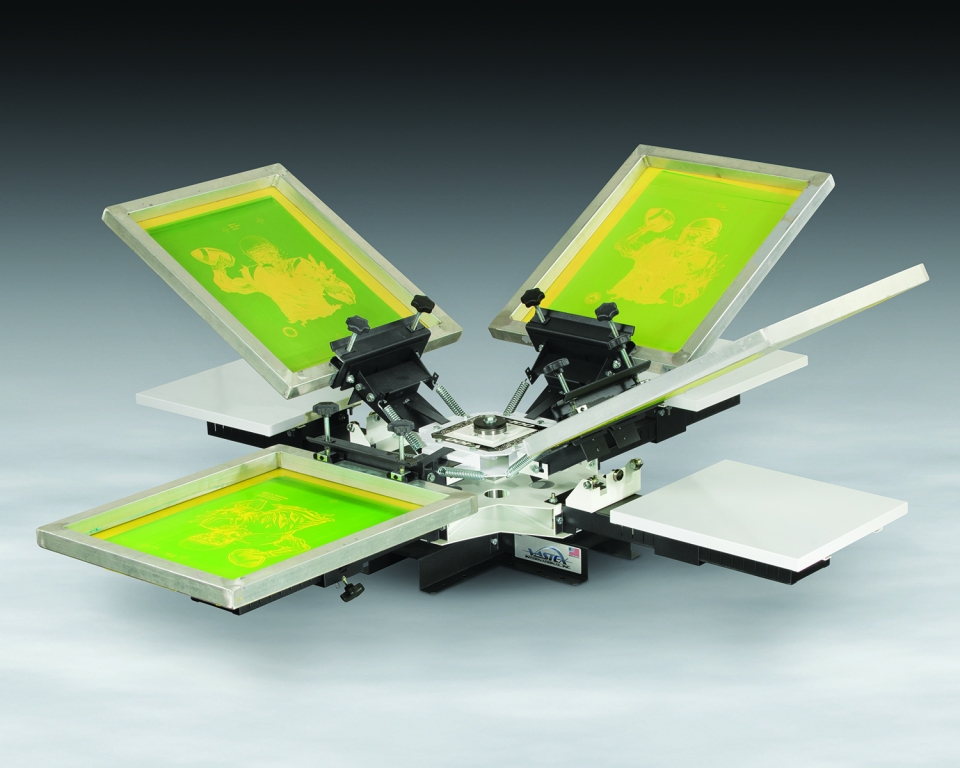

Vastex has introduced the V-100 line, a series of tabletop garment screen-printing presses that can be used in mobile operations, home shops, and other restricted spaces. Users can choose from expandable configurations ranging from one to four stations and 1 to 4 colors.

Vastex has introduced the V-100 line, a series of tabletop garment screen-printing presses that can be used in mobile operations, home shops, and other restricted spaces. Users can choose from expandable configurations ranging from one to four stations and 1 to 4 colors.

The series employs no-warp steel pallets, screen off-contact and level adjustments, rotor detent for positive engagement of platens, and three-point bearing locks for precise registration. Platens are available up to 21 in. wide. Compared to the company’s more industrial units, the V-100 line features lighter-weight constructions, tabletop-only configuration, and omission of features such as quick-registration micro controls.

Users with multiple stations can print all-heads-down for applications requiring spot and process colors, or for simultaneous printing of 1- and 2-color jobs.

Optional features include neck guides, rubber tops, and specialized pallets for printing on materials such as long sleeves, pant legs, caps, umbrellas, koozies, and more.

The V-100 presses are shipped disassembled in multiple cartons; the company reports that assembly time is approximately 2 to 4 hrs.

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns3 weeks ago

Columns3 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Case Studies3 weeks ago

Case Studies3 weeks ago