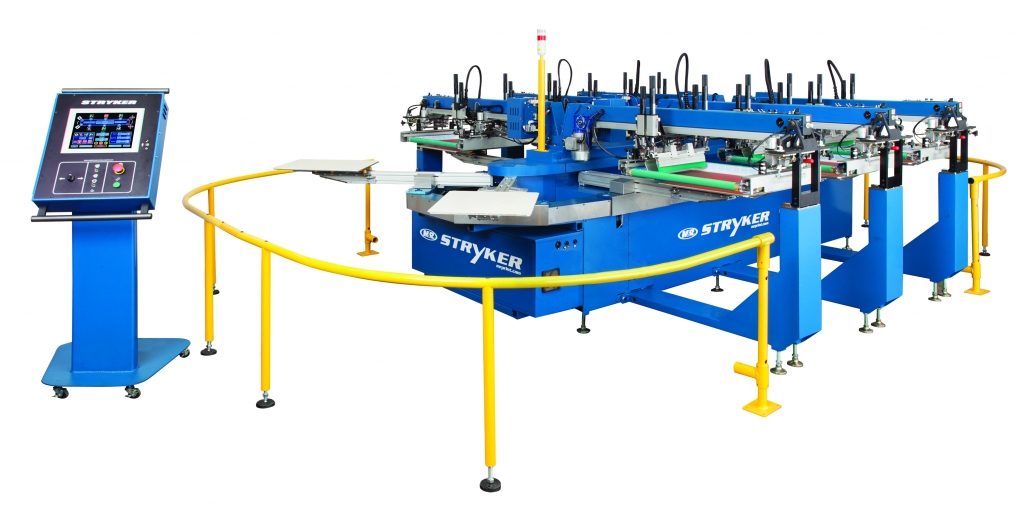

M&R’s Stryker oval-shaped automatic screen printing press begins with a 10-station base module. That base module can be expanded in 6-station increments to create 16, 22, 28, 34, 40, 46, and 52-station configurations. Other than the end stations, there are no restrictions on printhead placement. Because all other stations can support printheads—and any station can be left open, Stryker’s layout can be tailored to almost any production requirement.

M&R’s Stryker oval-shaped automatic screen printing press begins with a 10-station base module. That base module can be expanded in 6-station increments to create 16, 22, 28, 34, 40, 46, and 52-station configurations. Other than the end stations, there are no restrictions on printhead placement. Because all other stations can support printheads—and any station can be left open, Stryker’s layout can be tailored to almost any production requirement. Since Stryker’s oval shape takes up less floor space than comparable carousel automatic screen printing presses, it makes more efficient use of available production area. It also allows Stryker to fit into spots no carousel press could. Stryker features a maximum image area of 60 x 80 cm (23.6” x 31.5”). Its large color touchscreen control panel with icon-based labeling can display information and commands in multiple languages, and it features self-diagnostics and a production speed monitor to ensure more accurate job costing. The control panel sits on a caster-mounted pedestal, giving operators the ability to easily change position. Stryker has multiple print-stroke capability and an independent print-start/print-finish setting that automatically activates and stops printheads at the beginning and end of production runs.

The Stryker automatic screen printing machine features an all-new, highly-sophisticated servo-drive index system that combines simplified design with outstanding performance and reduced maintenance. Stryker’s smooth, high speed operation and precise control make it possible to achieve index speeds up to 900 pieces per hour. Index speed parameters can be adjusted quickly and easily. Stryker also incorporates multiple-indexing capability. Stryker’s printheads are driven by fast, reliable variable-frequency AC drive motors that deliver smooth print strokes and exceptional control. Simple print-stroke adjustment promotes exceptionally high production rates. Stryker’s printheads also incorporate an elegantly simple, tool-free method of adjusting off-contact at all four corners of the screen frame quickly and independently. There are independent print and reset buttons and independent print/flood speed controls on each printhead to make setup and operation fast and easy. Stryker’s high-lift mode simplifies screen loading, unloading, inspection and cleaning.

Stryker boasts a multitude of impressive standard features. M&R’s Laser Locator System speeds pallet positioning and changeover, and it assists operators in the precise positioning of garments and cut-piece goods. M&R’s exclusive Squeegee Dam™ system gently lowers the squeegee blade onto the screen mesh when the press is idle to help prevent thinner water-based and discharge inks from flowing into the image area. M&R’s electronically adjustable Ink Dip™ ink retrieval system keeps ink in the screen printing area. Stryker’s park feature facilitates setup and tear-down by simultaneously retracting the squeegee and floodbar and then moving them to the outside edge of the press for easy access. M&R’s Stryker automatic oval screen printing press, with its efficient design, high production speed, and modular expandability, is simply the most versatile press on the market today.

Advertisement

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns3 weeks ago

Columns3 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

News & Trends2 months ago

News & Trends2 months ago