Thomas Trimingham

How to Choose Between Digital Printing and Screen Printing

10 variables to consider when assessing artwork.

Published

3 years agoon

IT’S NEAR CLOSING time on Friday and your email dings. An order request from Craig – one of your loyal customers – and he wants a rush job for next week. Fortunately for you, this isn’t as big of a deal as it once was. You recently acquired a new service that can take care of rush orders without nearly as many headaches. You just installed a DTG printer. Now you can print direct-to-garment without doing separations, films, screens, or that costly setup you used to do for a screen printing job. This makes taking last-minute orders and/or small quantities doable; before, you would have sent them away.

When you fill out the quote request, because it’s a rush job, you start by picking DTG as the printing method, but then you pause… What if this isn’t a good job for DTG and it should be screen printed instead? How should you know which decorating method is the best for Craig’s order? These are common questions for apparel decorators, now more than ever, and the choices are not as easy as they first appear.

The way to navigate decisions like Craig’s rush order is to have a clear idea of how to apply several overlapping variables. First, you need to define what each variable is. Then, you can look at how each variable interacts to create a simple decision plan for your company. This may sound complicated, but it’s actually an essential step to avoid confusion and lost profits.

Picking the Best Method

For the majority of orders, it’s easy to decide the best decorating method based on a couple common variables: your pricing structure, fabric and garment type, art complexity, and the all-important order quantity. These are the four biggest factors that will guide an order in one direction or another. These variables mostly become important in that gray zone where you have an order request that can be completed either way, leading you to steer your customer toward the best method.

Pricing Each Decorating Method

The topic of pricing is a very complex issue. In the interest of keeping things simple, we’ll use a costing model. You’ll need to understand what your costs are to produce a product using screen printing as well as direct to garment. Each cost is then combined into a per print price. Then you can add a profit margin to see what the approximate charge should be. Before a final price structure is determined, there are some key things to consider like order setups, labor, consumables, media, and miscellaneous costs.

Setups

With screen printing, there’s a minimum number of garments that most decorators will need to create an order due to the setup costs. These costs include art setup, printing a positive, preparing a screen, exposing a screen, setting up the press, running a test print, and all of the labor and handling of each of these steps. Completing all of these steps for a single shirt isn’t a profitable process. One loose guideline that some screen printers follow is at least a dozen shirts per screen. So, a front and back print should have a minimum of 24 shirts, unless you can fit both sides on one screen; then it would be a dozen. There are a lot of exceptions to this rule depending on other variables, but it can help to quickly isolate orders that just shouldn’t be screen printed. Another common practice is to have a flat rate setup charge per screen ($25 to $30). This will make tiny orders too costly.

AdvertisementDTG has almost no setup – so it can seem very appealing for small quantities – but it isn’t without some costs. Most smaller machines require a separate pretreatment step, and heat pressing is often also recommended. This means you could have a couple minutes invested in just getting a single shirt ready to be printed.

Consider your pricing structure, fabric and garment type, art complexity, and order quantity.

Labor

One of the more contested charges for startup decorators is how to bill for labor costs. When you’re a one-person shop, it may seem like the best move is to not charge for labor and just add a margin on top of the cost of goods. Even some larger companies will “give away” labor and try to make up the costs on larger jobs or on overall volume. The trick to being consistent with this cost is part confidence and part big picture. Be proud and charge the price a good quality item costs; don’t undercut or discount your efforts! Charge labor as you would if you had an employee doing the job and you had to pay that person. Properly charging for labor is one of the best ways to understand how to estimate when to hire help and the value that should generate. If you struggle putting a number on this, estimate a bill for yourself per hour and then see what you would have to make to pay yourself an hourly fee. Hopefully you can afford yourself!

Consumables

This is the most obvious cost that decorators have. For screen printing, there’s the cost of a screen, film (unless a computer-to-screen is used), emulsion, ink, and cleaning chemicals.

For DTG, the main consumables are pretreatment and DTG ink, although there is some discussion that the printheads (and the amortization of these as they wear out) should also be included.

Media

Media is a printing term to indicate the object and surface that will be printed on. For the purpose of this article and the decorating methods being discussed, we’ll say the majority are T-shirts and decorated apparel. The cost of the garment is typically a very upfront cost that’s simple to include in your price. Where this can vary is if your printing method requires a specialty garment surface that’s more expensive than a standard product. For example, some DTG printers recommend higher quality garments.

Advertisement

The trick to being consistent with labor cost is part confidence and part big picture.

Miscellaneous Costs

This area should include shop overhead costs: electricity, water, waste, rent, etc. Other things to include are machine maintenance costs (can be critical with DTG), and payments on machine purchases or slow amortizations of existing equipment. Especially important to incorporate are taxes (including monthly or quarterly) and preparation costs, marketing costs, and other operating expenses that relate to your business such as attending tradeshows. Failure to properly estimate costs can come back to haunt you at the end of the year (if not sooner), so make sure to consult a good accountant while estimating your pricing.

The way to progress with a pricing model using costing is to take the basic costs of your media and consumables (estimated) and then add in an amount for miscellaneous costs of your shop. The miscellaneous costs are often broken down by taking an estimation of your total prints or services per month and dividing against your monthly miscellaneous shop expenses so you can apply a small amount to each service.

Before you finalize your pricing structure, you should analyze your competition and see what they’re charging to see if you’re competitive. If for some reason you aren’t close to what they’re charging, spend some time to see what they’re providing and how they’re servicing their accounts. You’ll likely find they aren’t offering the same thing, or they’re selling cheaper garments, lower qualities, or both. It isn’t a bad thing to not be the cheapest decorator in your area, as long as your clients understand what they’re paying for.

The final step is to figure out what profit margin to add to your orders. Depending on your costs, your competition, and industry standards, you should include a margin that will encourage orders, but not undervalue your products and services.

Once you have your costs and pricing structure solidified, it’s onto the next hurdle: how to guide customers to rapidly choose a printing method. Now it’s time to look at the fabric and garment concerns.

AdvertisementFabric and Garment Type Variables

This area can be a simple yes or no choice depending on the DTG system you have and what the order requests for finished products. The majority of DTG printers on the market can’t print on poly garments, so orders with that requirement will not be applicable if your printing method won’t work with it. There are also cotton/poly blends that many printers can have challenges with for DTG, so you’ll have to review what the recommended fabrics are and make sure you quote or guide your customers accordingly.

The second challenge is if the garment can be properly loaded and printed on your equipment, using the requested printing method. Depending on your system, you may not be able to load a unique garment with plackets, pockets, buttons, or zippers. The garments that have these challenges can damage your DTG unit or require special screen printing pallets.

A final concern for DTG and screen printing orders is the color of the fabric for the order. In the case of DTG, some garment colors are not ideal for pretreatment or for certain images. With screen printing, the color of the garment may require additional under printed white bases as well as bleed blockers to manage the color and control it to make the final print look decent.

Check the artwork size before deciding between screen printing and digital printing.

Art Complexity Challenges

The exciting thing about DTG printing is that it can open up the possibility for complex artwork to be printed in small-order quantities. For this to work well, it’s important you have a good idea of what type of artwork, and quality of source file, are needed to create an acceptable final product.

In addition to the complexity, it’s also important to understand what artwork will reproduce well using a specific method and what will likely come out better using another. For instance, DTG has a harder time printing large, geometric areas of flat colors. This type of image will tend to show any printhead imperfections. Considering this issue, a piece of artwork might be very complex, but also not a great candidate because the final result won’t reproduce well using DTG. It will need to be screen printed.

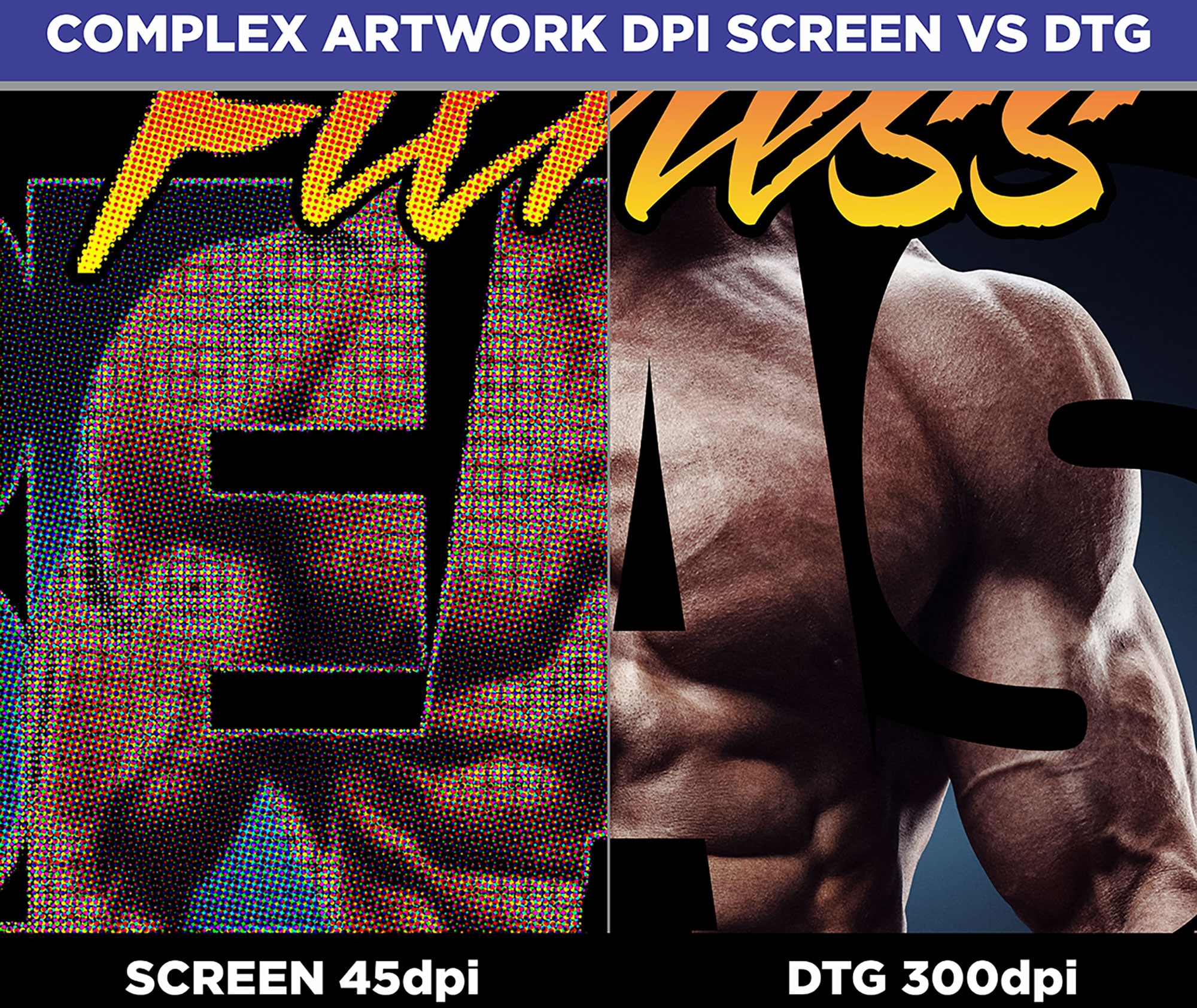

A similar issue with screen printing is the halftone dot or memory color issues. Screen printing typically needs larger dots to hold halftones on a screen (45 to 55 dpi is a common dot count). For some images, this halftone size may produce an unacceptable level of image distortion or fuzziness. There are also specific colors in images that are coined “memory colors” that can wreak havoc with screen printing. Trying to print images with flesh tones, wood tones, metal/chrome, and grass or nature scenes are particularly hard to reproduce using the limited gamut of screen printing. Our eyes can quickly detect errors in these “memory” colors because we have sensitivity attuned to these. In these cases, a DTG print can be a faster solution because of the larger gamut and control of the colors available.

Putting All the Variables Together with Order Quantities

Deciding what printing method to use becomes easy for 80 percent or more of your orders if you’ve done the steps to estimate your costs, reviewed the garments and art complexity, and compared these against the quantity of the order.

There are some fundamental sorting concepts to help with this process:

For most orders, a request of less than a dozen shirts is only for DTG or it isn’t worth it. This is depending on the art being simple to drop in and the garments being workable for this process. Of course, this assumes the customer will pay the increased cost of DTG printing, which is commonly $22 to $28 per garment or more.

The opposite is also true in that most orders of over 50 garments are better to replicate using a screen printing process, assuming the order artwork is simple and non-complex.

When the artwork is complex, and a good fit for DTG, but the quantity requested is borderline for either method, then it’s important to discuss with the client what they want the final printed product to be like in look and feel. Each method has innate advantages and some drawbacks that an experienced decorator should be able to call out for their clients. A final consideration to these situations can also be if your company has a preference in quality, durability, or look and feel that you favor from one method or another for the type of customer you’re working with.

Note: There are also additional decorating methods that are rapidly becoming more available for local screen and digital printers. Hybrid printing, which is a method that uses both screen and digital printing, can be an option if a printer in your area offers it. This process can overlap with larger quantities as opposed to traditional DTG, while providing higher details and durability. There are also some industrial DTG printing machines available at some larger companies that can have lower costs per piece, as well as higher volumes for additional possible solutions depending on the order and the specific needs.

Once you’ve done the work to price your services, your customers will often define the method before you get too far into the details. But, in case there are questions, you can consider the garments and fabric and the artwork complexity. Then decide, based on the order quantity, what the best option for your customer is that still makes you a comfortable profit.

Thomas Trimingham has been helping screen printers for more than 25 years as an industry consultant, artist, and high-end separator, and author of more than 175 articles. He currently is the director of marketing for M&R Printing Equipment. For more information or to comment on this article, email Thomas at thomas.trimingham@mrprint.com.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Atlantis Headwear Goes Solar for Sustainable Future

Comfort Colors Announces New Proprietary Dyeing Process Called “Pigment Pure”

10 Production Scheduling Secrets That Will Have Your Team Ready to Rock

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Latest Feeds

Advertisement

Most Popular

-

Columns1 month ago

Columns1 month ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note4 weeks ago

Editor's Note4 weeks agoLivin’ the High Life

-

Press Releases1 month ago

Press Releases1 month agoSports Inspired Clothing Market: The Influence of Sports on Fashion Forward Looks

-

Marshall Atkinson4 weeks ago

Marshall Atkinson4 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Case Studies1 month ago

Case Studies1 month agoScreen Printing for Texture and Depth

-

Press Releases3 weeks ago

Press Releases3 weeks agoHope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?

-

Headlines1 month ago

Headlines1 month agoLive Poster Printing Raises $30K for Charity