Andy MacDougall

Next Gen Printers

Expand your horizons … and we all live happily ever after.

Published

5 years agoon

WITH PRINTING UNITED APPROACHING, it brings us face to face with the future of print (doesn’t it every year?) and what may be the final transformation of a tradeshow that was originally started by screen printers. We’ve heard the word from above about all these other sectors moving in – offset, flexography, packaging, converting, 3D, and more – with the idea being, if our regular SGIA attendees come for the specialty graphics part they may wander to the next hall to look at some of the other areas in print manufacturing. Or, in a perfect world, the big printers running Heidelbergs or Manroland Goss web presses will become curious about opportunities in digital or – wait for it – screen printing… and we all live happily ever after.

As a sub-sector (screen and large-format digital) of both print and manufacturing, we have to hope we remain relevant and in the mix. From a screen printer’s perspective, whether you’re textile, graphic, or industrially inclined, we’re a small part of a much bigger pie. Our slice seems to be getting bigger as our two imaging technologies continue to grow. And it’s good growth – we’re not poaching existing work from offset and the other paper printers, we’re creating new markets, new uses, new products, and refining what we have. Take a bit of pride as a squeegeedragger that the men and women who perfected this process in the early 1900s and invented the thousands of products that still make our world go round decided to have an annual convention and exhibition back in the late 1940s and spun the screen process into an industry. That association morphed into SGIA and has now evolved into Printing United. We can now safely drink the digital Kool-Aid. We can automate cleaning, coating, imaging, and burning stencils. We can branch out into other sectors like packaging and industrial. We can sell online. We can do a lot of things to help grow a business, to improve our products, serve our customers, to remain in the game. No, to excel at the game.

But we can’t do any of this without young, trained, motivated personnel. I think this is also true in the other print processes.

Most readers know this is one of the critical underlying factors behind the success or failure of a business. You can have the best, most modern machines money can buy, but they don’t run without skilled operators. It’s the people, stupid. (Not to be confused with stupid people.) So, what’s being done?

I caught up with Johnny Shell, VP of print technology and training at SGIA, fresh from his side gig as chair of the screen-printing technology and sublimation competitions at the SkillsUSA National Leadership and Skills Conference held in Louisville, Kentucky, in June. He and his growing group of industry vets are on it. “We love to complain that we can’t find skilled labor for our printing business, yet only a few will step up to the challenge of becoming involved (in training, in their region). By doing so, a more sustainable future for our industry is all but guaranteed,” Shell says.

AdvertisementShell was part of an industry team that included Lon Winters (Graphic Elephants), James Ortolani (PolyOne), Dennis Slutzky (M&R), Tiffany Rader Spitzer (Roeder Industries), John Kupka (Saati Americas), Matt Marcotte (T&J Printing Supplies), and Betty Bassett (retired from Classic Design Screen).

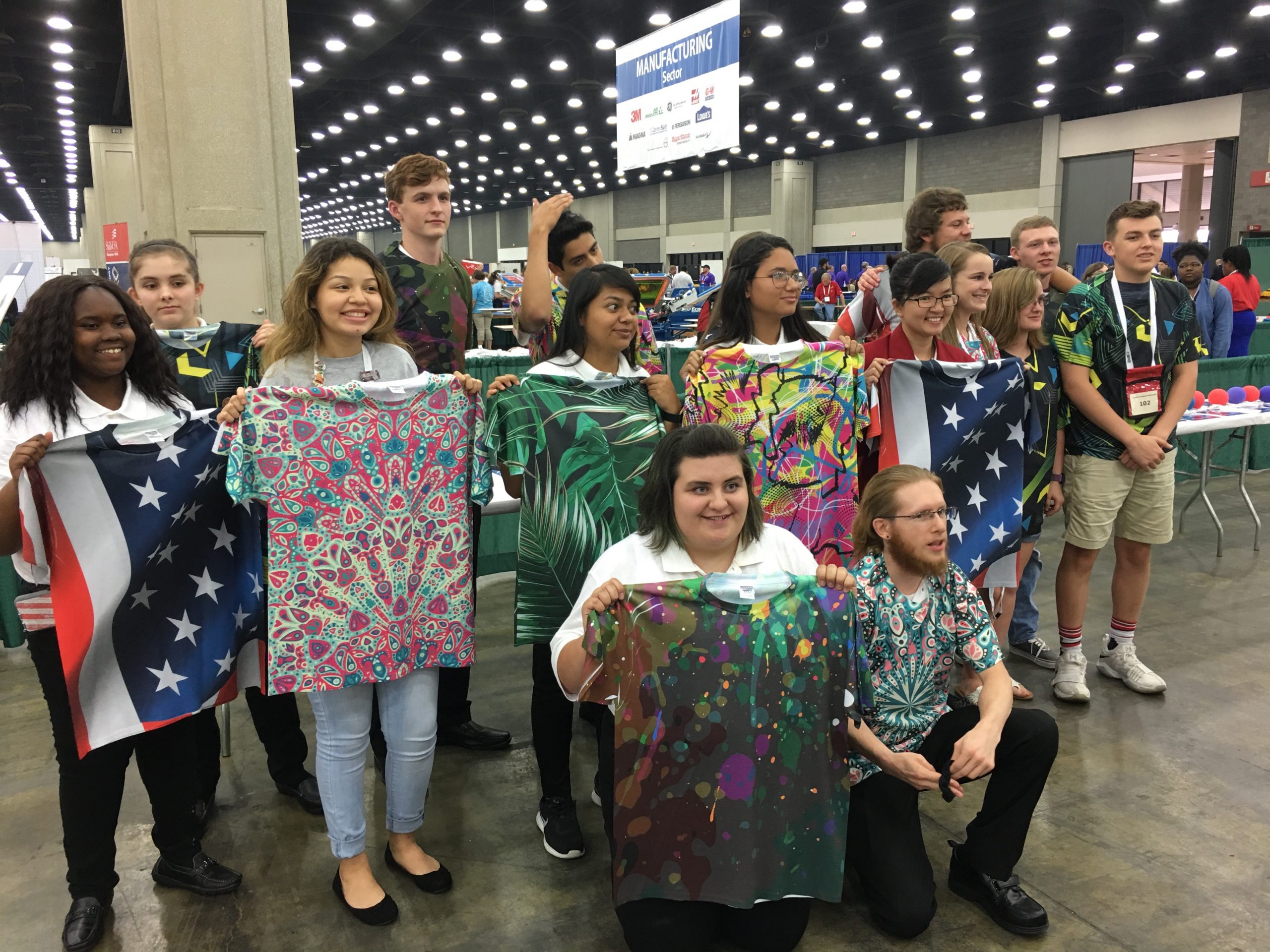

They’re the judges at the SkillsUSA national competition in screen-printing technology. This year, 30 states sent competitors from high school and post–secondary programs who won at regional and state championships.

They’re the judges at the SkillsUSA national competition in screen-printing technology. This year, 30 states sent competitors from high school and post–secondary programs who won at regional and state championships.

Shell explained the skill sets they tested for, developed to measure each contestant’s knowledge and abilities. Criteria is supplied to all participating schools.

The screen-printing technology competition evaluated the skills of student competitors on:

1. Tensioning mesh using a pneumatic tensioning system

2. Using an automatic coating machine

3. Exposing a screen

4. Registering the final screen on a 3-color print

5. Printing as many 6-color T-shirts as possible in a given time period

Students were scored on a quality assessment where they rated several finished products with varying degrees of quality defects. They presented a resume and went through a pseudo-job interview that included questions to assess their ability to handle work assignments, answer questions using technical terms, handle situations in a professional manner, and demonstrate critical thinking and a realistic self-concept. Finally, student competitors completed a 50-question written assessment to test their knowledge of screen printing.

Do your recent hires have this basic skill set? Do your long-term employees? I can’t do some of this, and I’ve been screen printing nearly 40 years.

Advertisement“If we want to solve the skilled labor shortage, we as an industry must get involved. Invite a school into your shop for a tour/demonstration. Kids are easily persuaded at a young age, so showing them the coolness of print is a way to spark their curiosity. Check with your state SkillsUSA to see if they have competitions. If they don’t, help establish one. If they do, get involved by helping secure necessary equipment, or help judge,” Shell says.

Skills shortage in print – all print, not just screen – is a critical problem. Who will run those shiny machines on display in Dallas? Read the full, online-exclusive interview with Johnny Shell below.

Q: What categories at Skills USA relate to Specialty Graphics?

There are several competitions related to specialty graphics: Screen Printing Technology, Graphics Imaging-Sublimation, T-Shirt Design. I serve as Chair for the Screen Printing Technology and Graphics Imaging-Sublimation competitions.

Q: Who was on your tech team at the event? (Name, company affiliation)

Judges for the Screen Printing Technology Competition: Lon Winters (GraphicElephants.com), James Ortolani (PolyOne), Dennis Slutsky (The M&R Companies), Tiffany Rader-Spitzer (Roeder Industries), John Kupka (Saati America), Matt Marcotte (T&J Printing Supplies), Betty Bassett (Retired).

Judges for the Graphics Imaging-Sublimation Competition: Aaron Montgomery (MontCo Consulting, 2 Regular Guys podcast), David Gross (Conde), Henri Coeme (HIX Corporation), Michael Wickman (HIX Corporation), Ray Weiss (SGIA)

Q: How many competitors/states send contestants?

To compete at the National Championships, a contestant must win at their regional level and then win the State Championship. In 2019, we had 30 contestants for Screen Printing Technology and 20 contestants for Graphics Imaging-Sublimation. The numbers are growing but slowly. Due to inadequate regional and state competitions, many National competitors never compete at the lower levels. They win by default.

Q: Give a quick overview of what the kids get tested on – does this testing follow any of the SGIA curriculum?

The testing plan is developed by the SkillsUSA Technical Committees for each competition. The technical committee reviews and updates the plan to assure it meets industry requirements. The testing standards are made available to all SkillsUSA chapters to use in the classroom.

Below is what was tested for each competition:

The Screen Printing Technology competition evaluated the skills of student competitors on

– tensioning mesh using a pneumatic tensioning system,

– using an automatic coating machine to coat a screen,

– exposing a screen,

– registering the final screen on a 3-color print,

and finally, printing as many 6-color t-shirts as possible in a given time period.

Students were also scored on a quality assessment where they rated several finished products with varying degrees of quality defects (none, minor, major). They also were scored on an oral assessment (pseudo-job interview) that included questions to assess their ability to handle work assignments, answer questions using technical terms, handling situations in a professional manner, demonstrate critical thinking and a realistic self-concept. A resume is also presented to the judge at the beginning of the interview. Finally, student competitors must take a 50 question written assessment to test their knowledge of screen printing.

The Graphics Imaging-Sublimation competition evaluated the skills of student competitor’s on transferring images to hardboard and license plate blanks, and executing a full sublimation workflow that included designing the front and back of an all-over-print for a polyester t-shirt using Adobe® Illustrator®, printing the front and back transfers to a wide-format sublimation inkjet printer using a RIP, and transferring the images correctly to the front and back of the t-shirt using an oversized heat press. Students were also scored on a quality assessment, oral assessment, and a 50 question written assessment.

Q: You have been doing this for a while – do you know if the students who are competing go on to get jobs with SGIA members?

Yes, many of the students go on to find jobs within industry. Many of the post-secondary students already have jobs before coming to the National Championships. We’ve had a few of the judges find employees from among the competitors which is a great result from their involvement.

Q: Which states/schools have strong competitors – can we name a few teachers and schools that continually place top students?

California, Missouri, Massachusetts, Illinois, Wisconsin, Georgia, Florida. I rarely know teacher names (other than Brian Schaffner-Waynesville Career Center, Missouri)

Q: Is there any connection between SGIA Education Connection, participating schools/students at Skills, and the Tom Frecska competition?

The SGIA Education Connection has been discontinued. Several contestants in SkillsUSA also participate in the ASDPT Tom Frecska Student Printing Competition and the SGIA Scholarship. Last year (2018) one of our scholarship recipients was also a competitor in World Skills…that’s the next level above the national championships!

Q: Anything the rest of the industry can do to strengthen or grow participation?

We need prizes from suppliers to setup the schools with the right tools and equipment. Many do not have adequate materials and supplies to effectively teach. We also need prizes for students, to keep them engaged. It’s the Apple model, put a Mac in every classroom and guess what the kids buy?? If we want to solve the skilled labor shortage, we as an industry must get involved. Invite a school into your shop for a tour/demonstration. Kids are easily persuaded at a young age so showing them the coolness of print is a way to spark their curiosity. Check with your State SkillsUSA to see if they have competitions. If they don’t, help establish one. If they do, get involved by helping secure necessary equipment, or help judge. I also need judges to help with the Nationals.

Q: Anything you would like to add?

We love to complain that we can’t find skilled labor for our printing business, yet only few will step up to the challenge of becoming involved. By doing so, a more sustainable future for our industry is all but guaranteed.

And yes, we still have the SGIA Scholarships. In 2019-20 academic year, we will give 20 scholarships in the amount of $2,000US. It caps in 2020-21 at 25 scholarships of $2,000US each.

At the WorldSkills level, they group skills into six sectors (Construction and Building, Creative Art and Fashion, IT and Communication Technology, Manufacturing and Engineering Technology, Social and Personal Services, Transportation and Logistics). “Print” falls in the Creative Art and Fashion sector but is classified under Graphic Design Technology). There aren’t any pure printing technologies but I’ll bet we could raise a stink about it and get it in there.

Donors

Adobe

Beaver Paper & Graphic Media Inc.

Condé Systems Inc.

Easiway Systems Inc.

Epson America Inc.

Fruit of the Loom Inc.

GraphicElephants.com

Great Dane Graphics

HIX Corporation

Newman Roller Frames mfg. by Stretch Devices

PolyOne Corporation

Saati Americas Corp.

The M&R Companies

Vastex International Inc.

Wasatch Computer Technologies

Andy MacDougall is a screen printing trainer and consultant based on Vancouver Island in Canada, and a member of the Academy of Screen & Digital Printing Technology. If you have production problems you’d like to see him address in “Shop Talk,” email your comments and questions to andy@squeegeeville.com

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

The Profit Impact of a Market Dominating Position

Inkcups Announces New CEO and Leadership Restructure

Hope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

SUBSCRIBE

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Latest Feeds

Advertisement

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?