Articles

Display Graphics

Published

24 years agoon

Specialty graphic applications for screen printing are nothing new. In fact, for many years the screen-printing process has thrived on creating display graphics that were deemed impractical for other printing processes. Today, however, several unusual materials for producing intriguing displays are being explored with a variety of printing technologies. These products include lenticular film, electroluminescent film, electrostatic film, and electronic ink. The suitability of these materials for screen printing and their availability to the general market may vary, but they are worth exploring because of their potential for creating truly unconventional and eye-catching displays.

Lenticular imaging

Developed in the 1940s and initially prized for its novelty value, lenticular imaging gives the illusion of motion or enhanced dimension to a two-dimensional print. One of its first product applications were “I Like Ike” presidential campaign buttons. Soon after, imaged lenticular cards began appearing in cereal boxes. But cost and technological limitations restricted the process to very small-format items.

Thanks to developments in plastic technology and computer software, however, lenticular images can now be produced on a larger scale. Today’s applications include everything from novelties, such as cards, toys, and mouse pads, to packaging and display graphics.

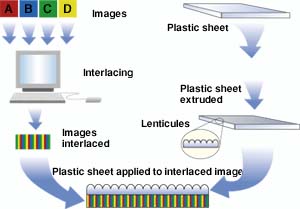

The basic construction of a lenticular display includes two components: a clear plastic sheet comprising optical-grade parallel lenses and a graphic design consisting of multiple segmented images that are viewed through the sheet (Figure 1). The lenses, which give the sheet a slightly ribbed finish, display only portions of the graphics beneath, sequencing through two or more distinct images as the viewing angle changes. The images that make up the graphic are “sliced” into dozens of strips per inch and reassembled with special software into a bewildering graphic that only makes sense when viewed through the lenticular sheeting.

AdvertisementLenticular film itself is an extruded plastic with precisely measured, half-cylindrical plastic ridges that serve as the lenses. Common materials used for producing lenticular films include vinyl, acrylics, and hybrid plastics, such as Eastman Chemical’s Eastar PETG co-polyester. The films come in a variety of thicknesses and support different viewing angle ranges depending on the number of lenticules per inch.

The number of lenticules also influences sheet thickness: The more lenticules per inch, the thinner the sheet. Thicker-gauge sheets (about 62 mils) with fewer lenticules per inch are used for large-format applications, while sheets for P-O-P displays and posters generally run in the 25- to 35-mil range.

To produce lenticular graphics, two or more images are sliced into narrow bands and arranged in an alternating sequence through a process known as interlacing. The images are then printed second surface (or laminated as a graphic film) onto the lenticular film.

The combined width of the image strips below each lens equals the width of the lens itself (also know as pitch). So if the design calls for three images, the print will include a narrow band of image #1, followed by a narrow band of image #2, and then a narrow band of image #3, all beneath a single lens. This sequence repeats with subsequent strips beneath each remaining lens.

For any given viewing angle, only one image strip is visible per lens. But because of the way the strips are organized, the visible ones always correspond to the same image and the viewer perceives a single, continuous design. As viewing angle shifts, a different collection of strips comes into view and the viewer sees a new image (Figure 2).

The lenticular process can produce the following effects:

Advertisement• Flip The viewer can switch between two or more entirely different images simply by shifting the viewing position.

• Motion This effect creates the impression that the image is either rotating on an axis or moving in one or more directions.

• Morphing This creates the illusion of one image transforming into a totally different one.

• Zoom Using multiple sizes of the same image, this effect gives the appearance of an object becoming larger or smaller.

• Multi-phase animation This approach creates a short film clip, using as many as fifty captured video frames.

• Three dimensional This approach, which differs from the others, uses layering of multiple graphic elements to produce the illusion of depth in a two-dimensional image. When done correctly, it appears that the viewer can actually reach into the printed piece. Three-dimensional is the only lenticular effect that works if the viewer is standing still.

AdvertisementRecent advances in graphic-design software have transformed interlacing from a frustrating manual process to an exact automated procedure. Today, software suitable for segmenting and rearranging multiple images for lenticular applications range from basic packages like Flip! (Kutuzov Inc., Las Vegas, NV) to advanced products, such as Lenticular F/X or LD Pro Photo (each from Lenticular Development Co., Lake Elsinore, CA).

Traditionally, lenticular graphics have been produced photographically or printed with lithography. And more recently, digital imaging has emerged as an excellent method for this application, especially for shorter-run jobs.

In theory, screen printing should also be able to reproduce the complex composite images, but it’s hard to find anyone who is doing it. Part of the reason may be the major challenges that confront lenticular printers, including the need for extremely high resolution and high halftone line counts, as well as dead-on registration.

Mike Brooks, vice president of sales and marketing for National Graphics, Brookfield, WI, is keen to these issues. His shop has produced many lenticular images in recent years, but most are printed through inkjet or offset methods rather than screen printing. “When screen printing and lenticular imaging are mentioned in the same breath, the first question that comes to mind is typeface,” Brooks says. “Fine type always breaks up when we attempt a screen-printed lenticular image. Other processes like inkjet or offset simply do it better. Where screen printing has an advantage is the durability of its prints and the ability to make higher run lengths profitable.”

For screen printers to see a real opportunity in lenticular imaging, the format of lenticular graphics will have to increase from its current maximum of 4 x 8 ft. But so far, there has been little demand for grand-format lenticulars, and no extrusion-machine manufacturer has yet built a system that will produce a larger sheet. Larger-format graphics can be tiled together from smaller pieces, but aligning the sheets correctly is an extremely difficult task that can wreak havoc on the lenticular effect.

Brooks believes that when customers begin to demand larger lenticular images, a suitable extrusion machine would follow. “But for the most part,” says Brooks, “lenticular orders are 100 prints or less and have a campaign length of less than six months.” He adds, “It really comes down to price, quantity, and durability. There are many places in lenticular printing where inkjet is just a better method to produce the images. Like everywhere else, screen printing has to find its niche. The message to screen printers is that they have an upper hand with outdoor applications and run lengths. The only thing missing is the demand for these screen-printing advantages.”

Electroluminescent film

The light-emitting phenomenon known as electroluminescence was discovered in the 1930s and is most commonly seen in exit signage, backlighting for wristwatches and pagers, and emergency lighting systems. In recent years, EL technology has also been applied to signage, advertising applications, and decorative lighting.

An EL display, or lamp, is composed of layers. These include a phosphor-impregnated layer sandwiched between a back conductive layer and a clear conductive layer in front. As electrical current passes from one conductive layer to the other, it cause the phosphor to emit its trademark EL “glow.” Electroluminescent lighting is very thin and flexible and can run for an extremely long time on very little power.

Typically, EL lamps have been produced to order as custom products, making them an expensive proposition. But seeing an untapped potential for EL displays, LaserVisions Technology, Inc., Kelowa, BC, Canada, has developed a promising and economical new EL substrate for screen printers called Per’f-Alite.

Per’f-Alite is an unconventional vinyl substrate that acts like an electroluminescent lamp. It is the first and, so far, the only electroluminescent graphic film to reach the commercial market. At DPI 1999, Per’f-Alite was named Product of the Year and also received the 1999 Vision Award. The product also earned LaserVisions three out of five first place awards for Best Fleet Graphics by the Private Motor Truck Council of Canada.

Per’f-Alite is a 10-mil composite vinyl substrate that incorporates an electroluminescent film beneath its printable surface. When an electric current (110AC or 12V DC) is applied, the graphic takes on the appearance of a standard backlit display, but without the fluorescent tubes and ballast (Figure 3).

“This film produces flat-panel, broad-area illuminated displays,” says Myke Andriash, president and CEO of LaserVisions. “I like to describe it as a lamp as thin as a credit card and sometimes call it ‘electric vinyl.'”

Per’f-Alite comes in rolls or sheets, in widths up to 48 in. To facilitate the required electrical connections, two edges of the material feature continuous bus strips. The company provides an “electric glue” that allows users to attach connections to their graphics at any point along the bus strips. Graphics can also be die cut, but a one-inch stub of the bus strip must remain on the cut piece so that it can be connected with a power source.

Per’f-Alite is available in perforated and non-perforated formats. As a perforated film, it is similar in effect to a one-way film, appearing as a backlit graphic on one side and more or less invisible from the other. The non-perforated version is capable of showing one image by day and another by night, and either film can provide strobing or flashing illumination effects.

The natural-white film is compatible with screen printing as well as digital imaging. For digital images, including inkjet, thermal transfer and electrostatic, the image must be transferred to the Per’f-Alite material rather than directly printed on its surface. Screen printing, on the other hand, can be done directly on the substrate. Regardless of the imaging method, graphics should be produced with translucent inks to promote light transmission. To prevent damage to the material, air-drying inks are recommended.

According to Andriash, the product is especially competitive compared to conventional electric signage. Its properties make it attractive for a variety of applications, including billboards, P-O-P displays, and transit graphics. He also points out a number of advantages over electrical signage, characterizing the materials as low maintenance, vandal-proof, shock proof and vibration resistant. A Per’f-Alite display will remain operational when punctured or scratched, and the material is designed to seal out moisture from both the lamp and connector assemblies.

Per’f-Alite offers functional advantages as well. The even illumination of an EL display does away with the hot spots or uneven appearance common in graphics backlit with fluorescent lamps. Its illumination qualities also last longer than on conventional EL lamps and tend to fade away gradually as the lamp nears the end of its life, rather than just suddenly “burning out.” And because the material is flexible, it can be used for displays that need to curve around corners or protruding structures. It can also be folded up like a blanket for transport.

“We’re still in the early phases of recognizing the full potential of this film,” Andriash explains. LaserVisions Technology Inc. is more of a research, development, technical-support facility, selling rolls of Per’f-Alite material to outside manufacturers and then teaching them how to image, cut, and finish the material.

Electrostatic cling film

Static-cling films are popular substrates because they adhere to smooth surfaces without adhesives. But because of the “static-cling” moniker, it’s easy to assume that static electricity is what makes these substrates do what they do best: apply and remove very easily, with no adhesive residue.

The truth is, conventional static-cling films have nothing to do with static electricity. A heavy plasticizer load provides the physical and chemical properties that enable them to stick to smooth, non-porous surfaces, such as glass, polished metals, and some plastics. On porous or irregular surfaces, however, static-cling films adhere poorly, or not at all. Additionally, if the plasticizer migrates to the surface of the film (which it frequently does), ink adhesion becomes a serious problem.

Now, Permacharge Corp., Rio Rancho, NM, is challenging traditional cling films with a truly electrostatic material called ClingZ, a printable oriented-polypropylene substrate that literally goes where no cling film has gone before. Designed for short-term interior graphics, ClingZ (Figure 4) gets its adhesive properties from a permanent electrostatic charge. It sticks to almost any clean surface, including brick, chalkboards, drywall, wood, paper, carpet, textiles, and even condensation-heavy windows and beverage coolers. The film is repositionable like other cling films, but because ClingZ contains no plasticizers, ink adhesion is not an issue.

Although the material is less affected by dust than other repositionable films, ClingZ still features a peel-away paper liner to prevent contamination of the “cling” side of the film. The liner also makes the film easier to handle before application.

Like other cling-film substrates, ClingZ is compatible with many printing processes, including screen printing and digital printing. However, because heat can negatively affect the film’s static charge, Permacharge recommends using air-dry inks–typically epoxies and enamels–to print the material.

Ralph Giammarco, who helped develop ClingZ at Permacharge and is now serving as a consultant to the company advises, “Printers will also want to minimize the ink deposit on the film. The heavier the ink deposit becomes, the shorter the life-span of the static charge will be.”

ClingZ is sold exclusively through Transilwrap, Franklin Park, IL. It is available in clear or opaque varieties in rolls or sheets, all with custom widths.

Electronic ink

Imagine hundreds of department-store posters that can be remotely controlled and electronically induced to display a different message or graphic every few minutes. Think of a computer monitor that can be stuffed into your pocket like a handkerchief, or a flexible television that can be unfolded and hung on the inside wall of your camping tent. Consider T-shirt graphics as thin, durable, and flexible as plastisol prints, but capable of “broadcasting” video clips. Although few of these applications have yet been explored, the “electronic ink” that may make them possible already exists.

The idea of electronic ink has been around for decades, but it wasn’t until 1997 that it became a reality. That’s when a group of MIT engineers came up with a solution and created the first workable samples of electronic ink. They promptly formed a private company, The E Ink Corp., and have been working busily ever since to further develop the concept.

In 1999, their product, called E Ink, saw its first commercial application. The customer was Eckard Corp., a drugstore chain that installed displays made with the ink at 10 of its locations in Florida, Texas, Georgia, and New Jersey. Each 12 x 30-in. sign (Figure 5) contained two wide “bars” of E Ink, and the displays were all linked together so that the messages could be updated instantly from one location.

Though young, the technology is already making waves: Sources such as Popular Science, Industry Week, the Associated Press, and the US Defense Advanced Research Projects Agency (DARPA) are hailing it as potentially the most revolutionary printing invention since Gutenberg’s movable type.

For now, E Ink remains a proprietary product that E Ink Corp. uses to produce its own line of displays, marketed under the Immedia brand. But companies such as Xerox and Bell Laboratories are expected to unveil their own versions of electronic ink within the next few years. It’s likely that screen printing will become the preferred method of applying this ink, so we will be closely watching its progress.

Because E Ink is still in its infancy and undergoing further development, details on its uses, processing, and future marketability are, for the most part, closely guarded. But what we do know about electronic ink is pretty intriguing.

The secret of E Ink lies in the millions of tiny, spherical microcapsules that make up the ink’s “pigment.” Each of these capsules is filled with pigmented dye and white chips that react to positive and negative electrical charges, which either push them to the top of the microcapsule or pull them to the bottom (Figure 6). The microcapsules, each about 100 microns wide, are suspended in an opaque carrier medium.

In order for the microcapsules to yield the desired effect, the layer of E Ink is sandwiched between two clear, flexible pieces of film that contain grids of transparent electrodes. These electrodes apply charges to specific locations of the ink layer and control the movement of the white chips in the capsules. When areas of the top electrode have a positive charge, the negatively charged chips below these areas are attracted to the top of their microcapsules, giving the capsules a lighter appearance. When the charge is reversed, the pigment chips are repelled from the surface, making the capsules look dark.controlling these charges selectively, the ink can be made to resolve both text and graphic images. In other words, while the E-ink coating itself may be screen printed, the actual graphic message is created electronically. Control of the specific image is accomplished through special “messenger” software and communication options that include a two-way pager, handheld remote control, remote Web access, or computer networks.

Presently, the E Ink color palette is limited to blue, red, or green, and a display can be produced with one of these colors plus the white from the chips. The capability to produce four-color process graphics is in the works, but for now, the technology (as well as the color palette) is best suited for large displays with single lines of text greater than 2 in. high. Although a 1-sq-in. deposit of E Ink contains roughly 100,000 microcapsules, which would allow image resolutions high enough to support text for newsprint and books, limitations in the electronics presently hold resolution to no higher than 100 dpi.

Essentially, E-Ink has the same look and feel of conventional ink. It can be printed onto many surfaces, ranging from plastics and Mylar to paper and cloth. It is highly viscous and feels like screen-printing ink. Its developers report that it cures like other inks, but go no further in their explanation. Compared to conventional LED displays or electronic signage, electronic ink is thinner, more economical when applied to large surfaces, more durable, and is a more comfortable medium for people to read and handle. And in bright light, where other displays wash out and become difficult to read, E Ink does not. Also, electronic ink will hold an image for weeks at a time, even after power is cut off.

“E Ink is light reflective (not light emitting), meaning that it requires far less power than conventional electronic signage,” explains Russ Wilcox, vice president and general manager of E Ink Corp. “It only takes about 1 Watt or less to operate a typical E Ink sign, and it produces an effect that looks much like a printed image, rather than an LCD display or other electronic image. Fundamentally, E Ink is an electronic component. It has wires, has to be connected to a power source, and is a complicated system to put together. For those reasons it is, right now, better suited for posters and billboards.”

For the moment, E Ink Corp. is focusing on display graphics, although Wilcox does not discount the possibility of screen printers one day using its ink to directly image garments. As for its use in the general printing market, Wilcox says, “I don’t see this ink being broadly sold separately to screen printers or web offset printers or whatever, because it’s not that simple to operate with. I can, however, see us selling media that is then used by printers–perhaps using E Ink to add a graphic element to a design…. I don’t think E Ink will impact screen printers dramatically, at least not for quite a few years. But who knows? We’re still discovering new uses for it every day. If we ever do find applications where it’s useful to sell the ink by itself, it’s very likely that you’ll see it in screen printing first.”

Opportunities unfold

Whether the products discussed here are available for immediate use or are still easing out of R&D, they highlight the increasing sophistication that customers are demanding from their display graphics. Already, applications produced with these materials are standing out for their utility and the unique effects they deliver. And screen printers are well positioned to capitalize on all their capabilities.

Source List

E-Ink

45 Spenelli Place Cambridge, MA 02138

617-868-8088

Fax: 617-868-8089

Web: www.eink.com.

Eastman Chemical Company

PO Box 431

Kingsport, TN 37662

423-229-2000 800-327-8626

Fax: 423-229-1673

Web: www.eastman.com.

LaserVisions Technology Inc.

675 Evans Ct., #1

Kelowna, BC VIX 6G4, Canada

250-491-1211

Fax: 250-491-1333

Web: www.laservisions.com

E-mail: laservis@smartt.com

Permacharge Corp.

541 Laser Rd.

NE Rio Rancho, NM 87124

414-789-3153 800-795-1415

Fax: 414-789-3152

E-mail: perma@permacharge.com

Web: www.permacharge.com

Transilwrap Co. Inc. (exclusive distributor for ClingZ film)

9201 W. Belmont Ave.

Franklin Park, IL 60131

216-676-0600 800-321-8544

Fax: 216-267-9730

Web: www.transilwrap.com

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Looking Back at the Early Years of Screen Printing: A Color Separation Showdown

Gildan Donates Surgical Equipment to Mario Catarino Rivas Hospital

INX University Expands Online Curriculum Program

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Columns1 month ago

Columns1 month ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Press Releases1 month ago

Press Releases1 month agoSports Inspired Clothing Market: The Influence of Sports on Fashion Forward Looks

-

Editor's Note1 month ago

Editor's Note1 month agoLivin’ the High Life

-

Marshall Atkinson1 month ago

Marshall Atkinson1 month agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Press Releases4 weeks ago

Press Releases4 weeks agoHope Harbor to Receive Donation from BlueCotton’s 2024 Mary Ruth King Award Recipient

-

Case Studies1 month ago

Case Studies1 month agoScreen Printing for Texture and Depth

-

News & Trends2 months ago

News & Trends2 months agoWhat Are ZALPHAS and How Can You Serve Them in Your Print Business?

-

Headlines1 month ago

Headlines1 month agoLive Poster Printing Raises $30K for Charity