Articles

Get Production Rolling With Rotary Screen Printing

Published

21 years agoon

Most people think of screen printing as a flat printing process because the substrates are usually flat and decorated in a horizontal position. Screen printing is also associated with piece-decorating applications, in which individual sheets of substrate are printed one by one, usually on semi- and three-quarter-automatic flatbed presses that require manual loading and/or unloading.

When screen printing is used as a piece-printing process with manual material handling, screen shops sacrifice productivity. Businesses that invest in automatic, multicolor, inline flatbed systems regain some of this productivity by eliminating manual handling from all or most of the sequence. Yet throughput continues to be limited because every sheet of substrate still must pause at each printing station to receive the image.

The good news is that you don’t have to sacrifice the benefits of screen printing to overcome the limitations of flatbed printing technology. For many applications requiring efficient, high-volume, high-quality printing, rotary screen printing may be the answer.

What is rotary screen printing?

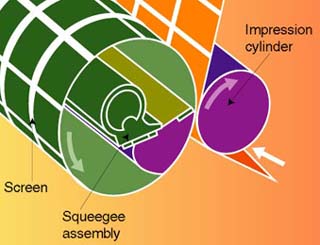

Rotary screen printing is so named because it uses a cylindrical screen that rotates in a fixed position rather than a flat screen that is raised and lowered over the same print location. Rotary presses place the squeegee within the screen. These machines are designed for roll-to-roll (web) printing on flexible materials ranging from narrow web films to wide-format roll textiles.

AdvertisementIn rotary printing, the web travels at a consistent speed between the screen and a steel or rubber impression roller immediately below the screen. (The impression roller serves the same function as the press bed on a flatbed press.) As the web passes through the rotary unit, the screen spins at a rate that identically matches the speed of substrate movement.

The squeegee on a rotary press is in a fixed position with its edge making contact with the inside surface of the screen precisely at the point where the screen, substrate, and impression roller come together (Figure 1). Ink is automatically fed into the center of the screen and collects in a wedge-shaped “well” formed by the leading side of the squeegee and the screen’s interior surface. The motion of the screen causes this bead of ink to roll, which forces ink into stencil openings, essentially flooding the screen without requiring a floodbar. The squeegee then shears the ink as the stencil and substrate come into contact, allowing the ink to transfer cleanly to the material.

In short, rotary printing is a continuous, stepless image-transfer method. The geometry of the screen and the position of the squeegee within the screen combine to provide both the screen-flooding and image-transfer functions in a single smooth operation that repeats with every revolution of the screen.

Rotary vs. flat screen printing

The virtues of rotary screen printing are most apparent when the process is compared to traditional flat screen printing.

Productivity Among the biggest attractions of rotary screen printing is its production speed. On a rotary press, images are applied to the entire width of the substrate as the material moves continuously through the printing mechanism–substrate size really has no impact on press speed. The only factor that determines the production rate is the speed of screen rotation/substrate movement (remember, these values are the same), which is limited primarily by the type and rheology of the ink being used. Because of the way rotary presses operate, their production rates are reported as linear measurements and typically fall within a range of 100-450 ft/min (30-100 m/min), depending on the model and the specific application.

AdvertisementThe situation is a little different with flatbed presses. On a flatbed press, printing is a two-step process that involves a pass over the screen by the floodbar to fill mesh openings with ink, followed by a squeegee pass to bring the stencil and substrate into contact for ink transfer. As previously noted, the flooding and printing action on a rotary system is all part of the same continuous motion, and separate strokes for these functions are not required. Not only does this approach reduce printing times, but it also removes the floodbar as a variable from the printing process.

Furthermore, to maintain good edge definition and ensure registration accuracy on multicolor prints, each sheet printed on a flatbed is held stationary (usually with vacuum drawdown from the press bed) during the print cycle. When you add the separate flood and print strokes to the equation, it’s clear that a flatbed’s productivity is influenced by substrate size, because the larger the substrate, the greater the distance the floodbar/squeegee assembly must travel and the longer the time required for each print cycle. If we look at manufacturer specifications for a range of common flatbed presses and convert their quoted production rates into linear speeds, it’s safe to say that these machines will support a printing speed up to 35-50 ft/min (10-15 m/min).

Material handling Because rotary presses work with web-fed materials, they eliminate the need to feed substrates into the press piece by piece, as is common with flatbed units. Users simply thread the desired material into a rotary machine from a reel at one end, and the machine continues to pull more material through as needed.

The substrate may continue through a drying unit after printing. Subsequently, it may be directed to a rewinding unit or on to another printing or finishing operation configured inline with the rotary press. With standalone flatbeds and multicolor in-line systems, getting the printed sheets to other finishing areas usually requires more cumbersome and time-consuming manual handling methods.

Off-contact and image integrity Off-contact distance between the screen and substrate during the print cycle is a critical issue for those who use flatbed screen-printing equipment. It is a non-issue for those who employ rotary presses.

In flatbed printing, screens are usually made from polyester mesh that has been stretched onto a frame. In order to achieve good printed edge definition and detail, press operators leave a small gap between the stencil and the substrate. During the printing cycle, the squeegee closes this gap, bringing the screen and substrate into contact by depressing the screen. The tension of the fabric causes it to “snap off” the substrate immediately behind the moving squeegee, allowing the transferred ink to retain the detail of the stencil. Without off-contact, the screen would tend to stick to the printed substrate and the image would be smeared or blurred.

AdvertisementThe problem is that the process of depressing the screen to transfer the ink also stretches the screen and the image it contains. This results in distortion to the printed image. The closer that the squeegee is to the edges of the screen, the greater this distortion becomes. What all this means is that some degree of image distortion always occurs with flatbed screen printing.

In contrast, rotary screen printing bypasses the whole off-contact/image-distortion issue. This is because on rotary presses, the surface of the cylindrical screen just makes contact with the web as it moves between the screen and the impression roller. Maintaining this line of contact is often referred to by rotary-press users as “kiss printing.” The off-contact in rotary printing is essentially zero because creating snap-off is unnecessary–the rotation of the screen away from the print surface serves the same basic function.

Combination printing

Is flatbed screen printing an inferior technique? Not at all! It is versatile and suitable for many applications, some of which are impossible to support on rotary machines, such as rigid stock printing. But one thing that can be done with rotary printing and rarely accomplished with flatbeds is inline combination printing.

Rotary screen-printing presses are modular in design and can be incorporated within production lines using other web-printing processes, such as letterpress, flexo, or offset. Roll-to-roll combination printing is used for many applications, such as labels for the cosmetic, personal care, and beverage industries; flexible packaging; graphic overlays; and even promotional graphics.

Combination printing allows users to take advantage of the various ink-deposit and detail-resolution characteristics of different imaging methods, which vary considerably. Looking at Figure 2, it’s apparent that if a combination-system user wants to deposit UV ink at a thickness of 30 microns, a rotary screen module would provide the best solution–rotary screen presses support deposits from 20 to as much as 300 microns, depending on the ink. But if the job calls for very fine details or high-re-solution halftones, using the flexo or offset printing modules of the combination system would be a better option. The point here is that combination units bring together complementary technologies to provide the most production flexibility.

With its heavy ink-deposit capabilities, rotary screen printing delivers the most opaque and brilliantly colored prints of the technologies employed in combination printing systems. For this reason, it often may be used to apply high-visibility image elements or produce undercoats in applications that will subsequently be printed with flexographic or offset images.

Rotary screen is also the best choice for coarse halftones and specialty inks, including metallic, thermochromic, and electroluminescent formulations.Another specialty of rotary screen is producing tactile images, such as Braille text. Rotary-screened varnishes and coatings are commonly applied to provide extra resistance to chemical and environmental exposure.

Sources of rotary screen presses

Although several companies manufacture rotary screen presses, two manufacturers dominate the market worldwide: Gallus, based in St. Gallen, Switzerland (www.gallus.com or www.gallus.ch), and Stork Screens B.V., headquartered in Boxmeer, The Netherlands (www. storknarrowweb.com). Both companies offer versatile systems, but their individual approaches to the technology are totally different.

Gallus Gallus has supplied rotary screen-printing modules for years as part of its combination presses, which are primarily marketed for their letterpress-, flexo-, and offset-printing capabilities. Gallus presses can be equipped with one or more rotary screen-printing modules, as well as hot-foil-stamping and inline-diecutting units.

Gallus supplies the R200 system for maximum web widths of 8 in. (203 mm). The company has an installed base of more than 1100 of these presses worldwide. A modular machine, the R200 allows quick and easy exchange of print units, including modules for letterpress, UV-varnishing, rotary screen printing, and curing. The Gallus EM 260, EM 410, and the EM 510 models support several configuration consisting of flexo, rotary screen printing, varnishing, laminating, and embossing modules. If desired, these units will even print the web on both sides. Each of these machines can be expanded to as many as 24 stations for producing labels, decorating cardboard products, and printing flexible packaging. The print width of these presses varies from 10 in. (254 mm) for the EM 260 to 20 in. (510 mm) for the EM 510.

The Gallus EM 280 machine has a modular, open structure (Figure 3). The machine, which is popular because of its high registration accuracy, is available with flexo and rotary screen-printing modules (up to 10 print stations total). The machine accepts rapid material loading, setup, and cleaning, and it supports a maximum web width of 11 in. (279 mm).

Gallus also supplies the TCS 250, which takes a slightly different approach than most web-fed printing systems in this category. While the machine supports offset, letterpress, and rotary screen-printing modules, it is considered an intermittent press because the web does not move continuously through the machine.

For its rotary screen modules, Gallus offers Screeny mesh, a nickel-plated stainless-steel fabric that is used to form Rotascreen printing cylinders. The fabric comes precoated with a photopolymer emulsion and a protective film, and it is offered by the meter in rolls or in sheets. Gallus offers eight standard types of Screeny printing plates, which vary from coarse meshes with approximately 64 openings per linear inch (ideal for Braille-printing applications) to fine fabrics with as many as 400 openings per linear in. (designed for halftone and fine-detail work).

Turning the Screeny mesh from a flat printing plate into a Rotascreen complete with imaged stencil is similar to making screens for flatbed screen printing. First, the film is punched with register holes. Then, the Screeny mesh is cut to the required printing length and punched with register holes that correspond to those in the film. Next, the protective foil over the emulsion is removed and the film positive is positioned by means of register pins. The mesh is exposed while flat under high vacuum to ensure that stencil captures even the finest image elements. Next, the photopolymer stencil is developed with a powerful water jet. Brief drying with hot air is required before continuing.

To create a cylinder form, the ends of the printing plate are connected with a plastic sealing device that is locked by means of heat. End caps, called stencil rings (Figure 4), are then attached to create a stable cylinder. The stencil rings also make it possible to connect the finished screens to the drive unit of the printing press. After printing, the Rotascreen ink is cleaned from the screen cylinders using a special automated screen-cleaning device. If the screens are no longer needed, the stencil rings are removed from the printing cylinders. The rings can be re-used for another job, but the mesh cannot be reclaimed–a new Rotascreen is created for every new job.

Stork While Gallus developed rotary screen printing units as a part of a combination configuration within the Gallus press, in the 1990s Stork developed the Rotary Screen Integration (RSI) program. The RSI concept is also based on compact rotary screen modules (Figure 5), but they are designed primarily for integration into existing roll-to-roll flexo, letterpress, offset, or gravure printing systems built by other manufacturers. Stork presently cooperates with more than 30 OEM partners to integrate rotary screen modules with their printing equipment. Stork will also provide standalone single or multicolor rotary screen systems.

The RSI module can be integrated on fixed positions in most existing narrow-web presses. Alternately, it can be mounted on a rail system that allows the user to move the module to any position in the printing line. RSI print modules are available with web widths of 10, 16, 20, and 24 in. (254, 406, 508, and 610 mm) and support for screen cylinders with a circumference of 12-24 in. (305-610 mm).

The screen cylinders used in Stork RSI print modules are made with RotaMesh, a non-woven screen that is made by electroforming thin sheets of nickel. The basic structure of the screen openings is hexagonal (Figure 6) to ensure optimum screen stability and promote registration accuracy. The screen material is essentially a rigid plate with holes.

Unlike the Gallus screen material, which is provided in flat form, Stork’s RotaMeshes are premanufactured. The material is supplied to press users as cylinders that are welded for durability. The material is available in 10 standard versions ranging from RotaMesh 75 (75 mesh openings per linear inch) for tactile-printing applications to RotaMesh 405 (405 openings/in. ) for printing very fine detail.

Because the screens are provided in cylindrical form, the stencilmaking process is much different than the flat processing method used with Gallus’s Rotascreens and requires special coating, exposure, developing, and cleaning equipment. First, the user applies stencil rings to stabilize the cylinder. Next, the RotaMesh is degreased in a tank built for the purpose. Then, direct emulsion is applied by means of a cylindrical emulsion applicator.

After coating, the screen is dried and the film positive is mounted to the outside of the cylinder. Permanent registration marks on the RotaMesh are used to ensure proper film alignment. For exposure, Stork has designed a unit specifically for its cylindrical screens. The system prevents undercutting of light during screen exposure. Finally, the screen is placed in a developer/stripper to resolve the stencil image. After drying, the RotaMesh screen is ready for use in printing.

When printing is complete, screens are placed in a screen washing system to remove ink. Once clean, the screens can be stored for repeat orders, or they can be returned to the automatic developer/stripper for reclaiming. Unlike the Gallus screens, Stork’s Rotamesh can be used several times.

Round out your productivity

Increasing throughput on the production floor is the main purpose served by rotary screen printing. But don’t overlook the other benefits of this technology, including increased image accuracy and the ability to work in conjunction with other printing methods. If your product line includes industrial graphics, labels, decals, or other applications that could be produced roll-to-roll, you owe it to yourself to give rotary screen technology a closer look.

About the author

Wim Zoomer is owner of Technical Language, Boxmeer, The Netherlands, a consulting and communication business focusing on screen printing and other printing processes. Zoomer has written numerous articles for screen-printing journals and is frequently called on to translate technical documents, manuals, and books between the English, French, Spanish, German, and Dutch languages. Visit his Website at www.technicallanguage.tiscaliweb.nl.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Arcus Printers Barracuda Conveyor Flatbed Cutter

The Profit Impact of a Market Dominating Position

Inkcups Announces New CEO and Leadership Restructure

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Case Studies3 weeks ago

Case Studies3 weeks agoScreen Printing for Texture and Depth