Articles

Mar-Tek Industries: Industrial Printing with a Personal Touch

Published

22 years agoon

When Irene Smith started Mar-Tek Industries in Englewood, CO, she wasn’t certain what specific markets the industrial screen-printing company would serve, but she knew that excellent customer service and product quality would be the foundations of the business. “We decided not to try to be all things to all people, just to look for large corporations that needed very precise, good-quality work that was consistent,” Smith says. “Those were our strengths.”

An early indication of the type of company Mar-Tek would grow to become was reflected in one of its first jobs, a demanding application for gas-pump manufacturer Gilbarco. “They came to me with a quality problem,” recalls Smith. “The faceplates on the front of their gas pumps were degrading and they didn’t know how to stop it.”

Smith and her small team of employees set out to devise a solution, first testing different types of inks and coating thicknesses, then looking to new substrates and overcoating methods. Eventually, they came up with a simple, yet revolutionary, solution: Rather than printing the graphics on the front side of the faceplate substrate as was common on gas-pump panels at the time, Smith’s team decided to second-surface print them on a clear hardcoated film. Printing the graphics in reverse on the back side of the film would allow them to be easily visible through the material while protecting them from exposure to fuel blends and normal wear and tear.

“It took a lot of trial and error on something that sounds so simple, because you can get locked into ‘Well this is the way it’s been done,'” Smith explains. In the end, she says, second-surface decoration changed the whole industry and became a standard that is still required by many gas-pump manufacturers today. It also established Mar-Tek’s relationship with Gilbarco, which was a $4-million customer for the printing company last year.

The high standards Mar-Tek sets for research, testing, and quality control helped earn the company a reputation for quality products and a growing list of clients in the petroleum, aerospace, telecommunications, and medical markets. “You build your reputation with years of good, credible quality and by doing business with integrity that customers can count on,” says Smith. “Sometimes you don’t always tell your customers what they want to hear, but you tell them what is real and what you can do, and then you do it.” With this direct and honest approach, Mar-Tek has taken only 14 years to grow from a handful of workers to an 80-employee company with gross annual sales totaling more than $8 million in 2001.

AdvertisementStarting small

Armed with a background in business and experience in the industrial screen-printing market, Smith founded Mar-Tek in 1987 inside an empty warehouse with a desk, a chair, a phone, one manual print table, and three employees. One of those employees was Emmett Butler, who had worked with Smith at Markon, an industrial sheet-metal manufacturing and precision screen-printing company. When Smith launched Mar-Tek, Butler decided to join her, and the pair were able to attract plenty of business to the young company. “As soon as [Markon clients] found out we had started our own business, all of the orders started coming in to us,” Butler says.

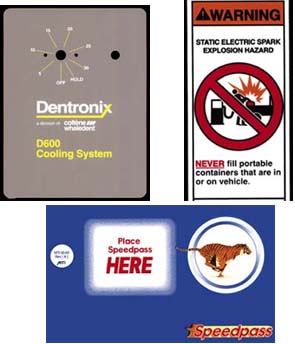

The screen-printing company started landing contracts with leading companies, many of whom are still customers today, including Lucent Technologies, Lockheed Martin, Anixter, Graybar, Celestica, Gambro Group, IBM, Tyco Power, Flextronics, and Qwest. And Mar-Tek also brought in new clients who were drawn to its reputation for printing a variety of demanding applications, including keypads, decals, custom labels, overlays, faceplates, and warning and descriptive labels (Figure 1).

Butler recalls the days when print production was supported only by the company’s manual print table, a T-shirt drying rack converted for drying industrial parts, and the car wash down the street, where employees would haul the screens for cleaning and reclaiming. The art department started out small, too, with a single typesetting machine, a layout table and paste-up board, and a large-format camera. About seven years ago, Mar-Tek began upgrading this area of its business, replacing outdated equipment, adding Macintosh computer systems, and later purchasing an Agfa Imagesetter.

Success also led the company to expand its printing capabilities (Figure 2), first by adding a 24 x 30-in. semiautomatic press and, over the next decade, by introducing three additional mid-format semiautomatic machines and two large-format semiautomatics to support larger graphics. The company also added two forced-air dryers and two UV-curing units, and in 1999, expanded its production capacity by opening a second plant in North Carolina.

Hands-on precision

AdvertisementWhile Mar-Tek uses its semiautomatic equipment for many of the jobs it produces, manual printing still plays a significant role in its production mix. For example, the company uses two custom-built manual print tables, which feature interchangeable print beds that can be fitted with jigs to hold odd shapes and 3-D parts.

Mar-Tek has six more manual print tables–also custom built–that it uses for printing backlit panels and similar applications. These tables incorporate a special glass print surface that can be backlit, making it possible to detect flaws and inconsistencies in a printed graphic before it even leaves the press.

Considering the high-tech nature of many of Mar-Tek’s clients, manual printing may seem an anachronism. But Mar-Tek has found it ideal for many of the industrial jobs it regularly faces. Among other things, the presses offer a degree of flexibility unmatched by any automatic machine and they are quick to set up. In the hands of Mar-Tek’s experienced printing staff, the presses deliver a remarkably high level of print quality.

“Competitively speaking, we find that [manual printing] is very good for us,” comments Neil Daley, Mar-Tek’s vice president of marketing and president of Image Tek, a sister company set up to address special printing, machining, and assembly needs for Mar-Tek’s customers. “A number of our competitors cannot, in a cost-effective way, produce a really short run because it ties up their standard screens and presses. We have a good job-flow process that allows us to do 3-4 pieces at a time without costing an arm and a leg for the customer or ourselves.” The company also relies on manual techniques in its screenmaking and screen-cleaning/reclaiming areas.

Other services

Mar-Tek offers a variety of finishing capabilities, including cutting technology that it uses primarily for overlay, faceplate, and label jobs. Today, the company’s cutting equipment includes three clamshell diecutting presses (Figure 3) and one digital cutting plotter, which has proven useful for short-run and prototype work. The company also has several laminating units.

AdvertisementIn addition to screen printing, Mar-Tek has always provided complete plastic machining and fabrication services. The company transferred these services to its Image Tek subsidiary when it was formed in 1998. “It became very evident as we were growing that we needed to separate out the machining, assembly, and packaging operations because they had their own special requirements and needs,” explains Smith.

Mar-Tek’s forte became general screen printing, while Image Tek began handling specialty screen printing, including applications that required a clean-room environment. Spray coating, kitting, and warehousing services are also offered through Image Tek’s 7000-sq-ft-facility, as are custom-fabricating capabilities that rely on milling (Figure 4) and precision cutting equipment.

To provide contamination-free screen printing, Image Tek built a clean room (Figure 5A) with a filtered air supply. The room is kept under positive pressure to prevent contaminants from seeping in, and static-control equipment is used to prevent substrates from attracting debris. Clean-room employees also wear protective suits with hats and boots to further prevent the release of airborn particles. Image Tek uses the clean room primarily for applications that require extreme accuracy and flawlessness, including fine-detail instrumentation, backlit graphics, and other high-end products.

Image Tek has its own screenmaking, exposing, and screen-cleaning equipment, but relies on Mar-Tek’s prepress department for film positives. Its printing equipment includes one semiautomatic press, two manual print tables, one custom-made print table, and one UV dryer.Anne DiNardo

Another contamination-free room of the facility (Figure 5B) houses spray-coating equipment for applying protective or gloss-reduction coatings to three-dimensional parts, particularly those designed for use on medical equipment. “Different applications require different degrees of clarity or reflectiveness on the lens,” explains Daley. “We’ll often work with a customer to define a certain gloss level and put matting agents in the coating to achieve that level.” The spray room is designed with an internal heater that can raise the room temperature to 175°F (80°C). This allows an operator to spray coat parts, leave the room, and then cure the parts without having to move them and risk contamination.

Daley acknowledges that there are up-front costs in installing a clean room and that discipline must be maintained in keeping it clean. But he added that it saves money in the long run by reducing rejects and wasted material.

Setting a new standard

Early on in its work, Mar-Tek set its sights on building a reputation for delivering highly-accurate close-tolerance printing, a goal that could not be achieved without developing stringent quality-control standards. Mar-Tek employees worked together to outline procedures for every stage of production so that jobs could be repeated accurately and consistently. “The employees that actually produce the parts write the processes and procedures,” says Smith. “Once we write a procedure down, we are all agreeing that this is the way it needs to be done.” This dedication to quality has helped Mar-Tek evolve from producing small one-or two- color jobs on vinyl or polyester to printing jobs with as many as 25 colors on Lexan and Plexiglass while maintaining registration tolerances of ± 0.005 in.

Standardization also helped Mar-Tek adapt to changes in the markets it serves, particularly when clients began slimming down their workforces and outsourcing more work. Prior to this change, Daley said clients would supply job specifications when they placed orders. Now, Mar-Tek is often involved in establishing job parameters relating to color matching, material performance, compliance with international standards, and part construction. “We used to kind of thrash around on the ground not knowing what to do when customers didn’t give us a quality standard,” Daley says. “Now we get that established and documented with our customers at the beginning so that when we’re done with a job there are no surprises.”

Daley attributes the company’s ability to offer such services to the large number of long-standing Mar-Tek employees who bring experience and knowledge to the company. Further proof of Mar-Tek’s commitment to quality standards is seen in its ISO 9002 certification and in-house training program.

In line with its quality standards, Mar-Tek is equally committed to research and testing on behalf of its customers. The company identified this need after it began working with the petroleum and medical industries, which required products that could stand up to specific on-the-job conditions. For example, Mar-Tek prints faceplates for kidney dialysis machines that must withstand hospital cleaning solutions and daily handling, as well as products for the petroleum industry, which require resistance to harsh chemicals and rough weather conditions. Explaining the emphasis Mar-Tek places on thorough testing, Smith says, “We’re putting our reputation on the line and asking customers to do the same when they change over to a new material we recommend.”

As part of its testing regimen, Mar-Tek uses accelerated weathering equipment (Figure 6) to determine how inks, substrates, and adhesives stand up to various environmental conditions. “Let’s say we have three recommended ink and substrate combinations for an application,” explains Daley. “What we like to do is prepare a sample of each one, put them all into testing, then evaluate them comparatively. That way we can advise our customers on what might be their best selection.”

Mar-Tek backs up its quality standards and testing methods with thorough inspection procedures throughout the production process. And at the end of a print run, each job goes through a final inspection. “We have quality checks all the way through laminating, adhesive application, and diecutting, and we even do a final inspection [before shipping] to verify colors again,” shares Butler. While the inspection process can be time consuming and hold up production, Butler said the additional effort helps Mar-Tek deliver on its commitment to quality.

Seeing the customer as a partner

Part of Mar-Tek’s philosophy on customer service is to view its relationships with customers as partnerships. In the past, Mar-Tek has worked to help customers streamline and refine their own production procedures for greater consistency. They’ve even worked directly with their customers’ engineers to redesign products for better performance. Smith adds that the company has also begun to help clients manage their inventories through global tracking systems and bar-coded products.

Mar-Tek is turning to its Website (www.mar-tekind.com) as a tool for strengthening customer relations. One new Web tool, Label Maker, assists customers through the label-design process. Customers identify specific criteria for the label application and the Web program recommends the best label construction for that job.

While Mar-Tek continues to look for new ways to improve its printing and production services, it has not strayed from the customer-service dedication that helped it grow. Recently, Daley supervised a development team that was helping a Mar-Tek client who needed to illuminate a large symbol on outdoor graphic equipment to indicate that the equipment was activated. The customer’s original backlighting was bright enough to illuminate the image, but the individual bulbs of the lighting system were visible through the graphic.

Daley’s team conducted several experiments using different diffusing films and inks. After about a year of testing, they developed a printable liquid mixture that maximized light output for the backlit sign without producing troubling hot spots or shadows.

Much like the redesigned gas-pump faceplates that made a name for Mar-Tek in the petroleum market, the diffusing solution is now opening up new opportunities for the company. Daley says another Mar-Tek customer is also using the diffusing technology on backlit displays and saving about one-third of what he was spending on diffusing film.

For Smith, these examples prove that building relationships with clients is a logical way to grow a company with a strong and promising future. “To me, customers make the best partners of all because it’s a win-win situation for everyone,” she says, pointing out that when Mar-Tek takes steps to help customers achieve their goals, the company is ensuring its own continued success.

SPONSORED VIDEO

Let’s Talk About It

Creating a More Diverse and Inclusive Screen Printing Industry

LET’S TALK About It: Part 3 discusses how four screen printers have employed people with disabilities, why you should consider doing the same, the resources that are available, and more. Watch the live webinar, held August 16, moderated by Adrienne Palmer, editor-in-chief, Screen Printing magazine, with panelists Ali Banholzer, Amber Massey, Ryan Moor, and Jed Seifert. The multi-part series is hosted exclusively by ROQ.US and U.N.I.T.E Together. Let’s Talk About It: Part 1 focused on Black, female screen printers and can be watched here; Part 2 focused on the LGBTQ+ community and can be watched here.

You may like

Advertisement

Arcus Printers Barracuda Conveyor Flatbed Cutter

The Profit Impact of a Market Dominating Position

Inkcups Announces New CEO and Leadership Restructure

Advertisement

Subscribe

Bulletins

Get the most important news and business ideas from Screen Printing magazine's news bulletin.

Advertisement

Most Popular

-

Case Studies2 months ago

Case Studies2 months agoHigh-Density Inks Help Specialty Printing Take Center Stage

-

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months agoF&I Printing Is Everywhere!

-

Andy MacDougall2 months ago

Andy MacDougall2 months agoFunctional and Industrial Printing is EVERYWHERE!

-

Columns3 weeks ago

Columns3 weeks ago8 Marketing Mistakes Not to Make When Promoting Your Screen Printing Services Online

-

Editor's Note3 weeks ago

Editor's Note3 weeks agoLivin’ the High Life

-

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks agoHow to Create a Winning Culture in Your Screen-Printing Business

-

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago“Magic” Marketing for Screen Printing Shops

-

Case Studies3 weeks ago

Case Studies3 weeks agoScreen Printing for Texture and Depth