AS SCREEN PRINTING companies plan for another year of operations, one thing is clear: equipment and ink manufacturers’ R&D departments have been working particularly hard. The following provides an overview of the latest advances in presses, dryers, inks, and more.

UNDER CONTROL

Speed and efficiency define the latest developments in automatic presses. From digital control panels to energy-saving measures, today’s autos are designed to provide quick ROI for mid- to high-production shops with efficiently run shop floors. For example, M&R’s Gauntlet 4 features a new, completely digital control panel with “all the bells and whistles that screen printers have always wanted,” says Mark Sulhadonik, textile applications specialist at equipment supplier GSG. “One of the key points is the single point of contact adjustment in the front and rear of the screen holder on each individual printhead. So with one quick turn of a knob, you can raise your off contacts up or down on each individual head.”

Additionally, users can operate all flash carrier units directly from the control panel. This enables decorators to stay in one place rather than walking around the press, which can slow production. Similarly, capability to control as many as eight flash gears from the main panel eliminates the need to stop the press and change the temperature, time, or power for each individual printhead.

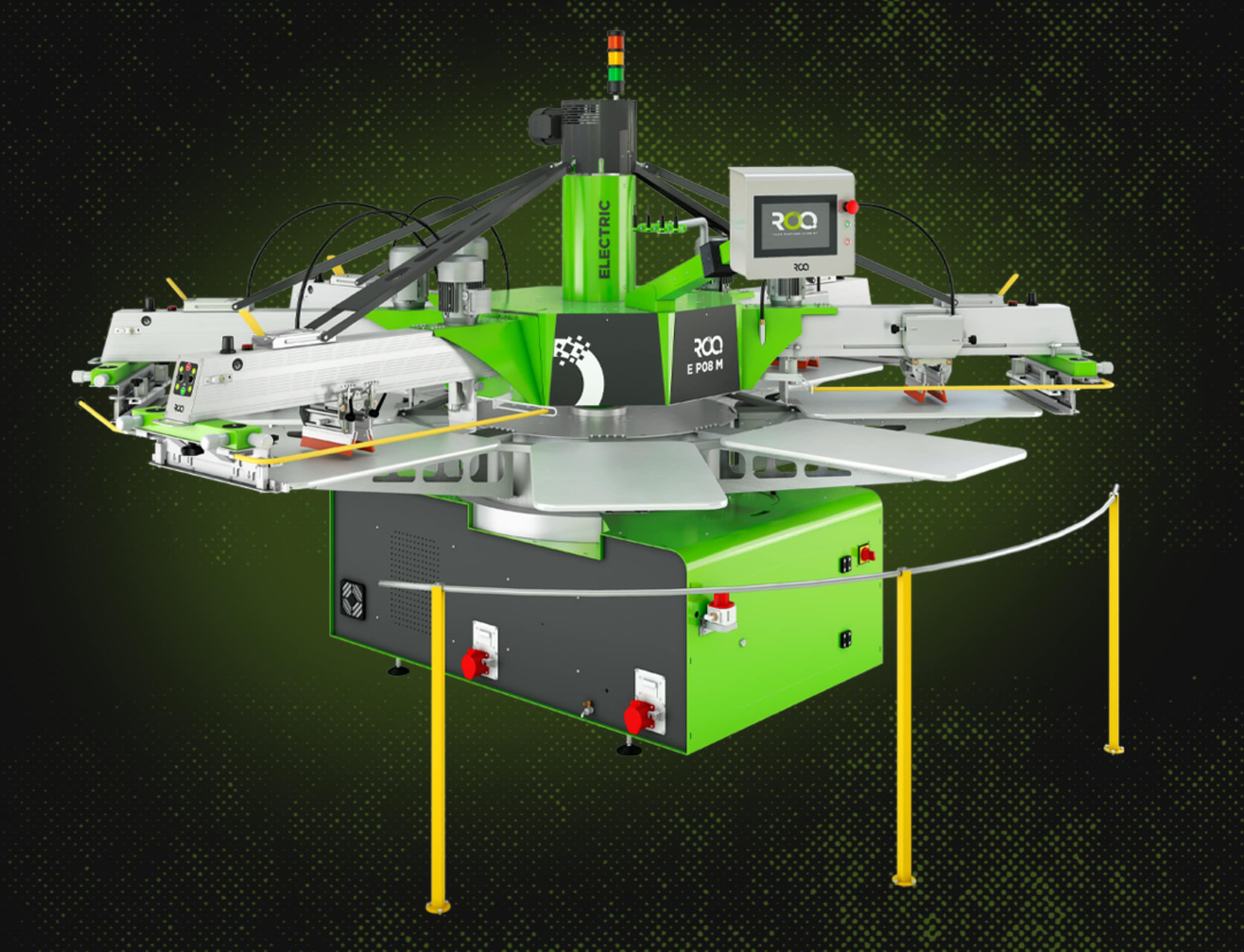

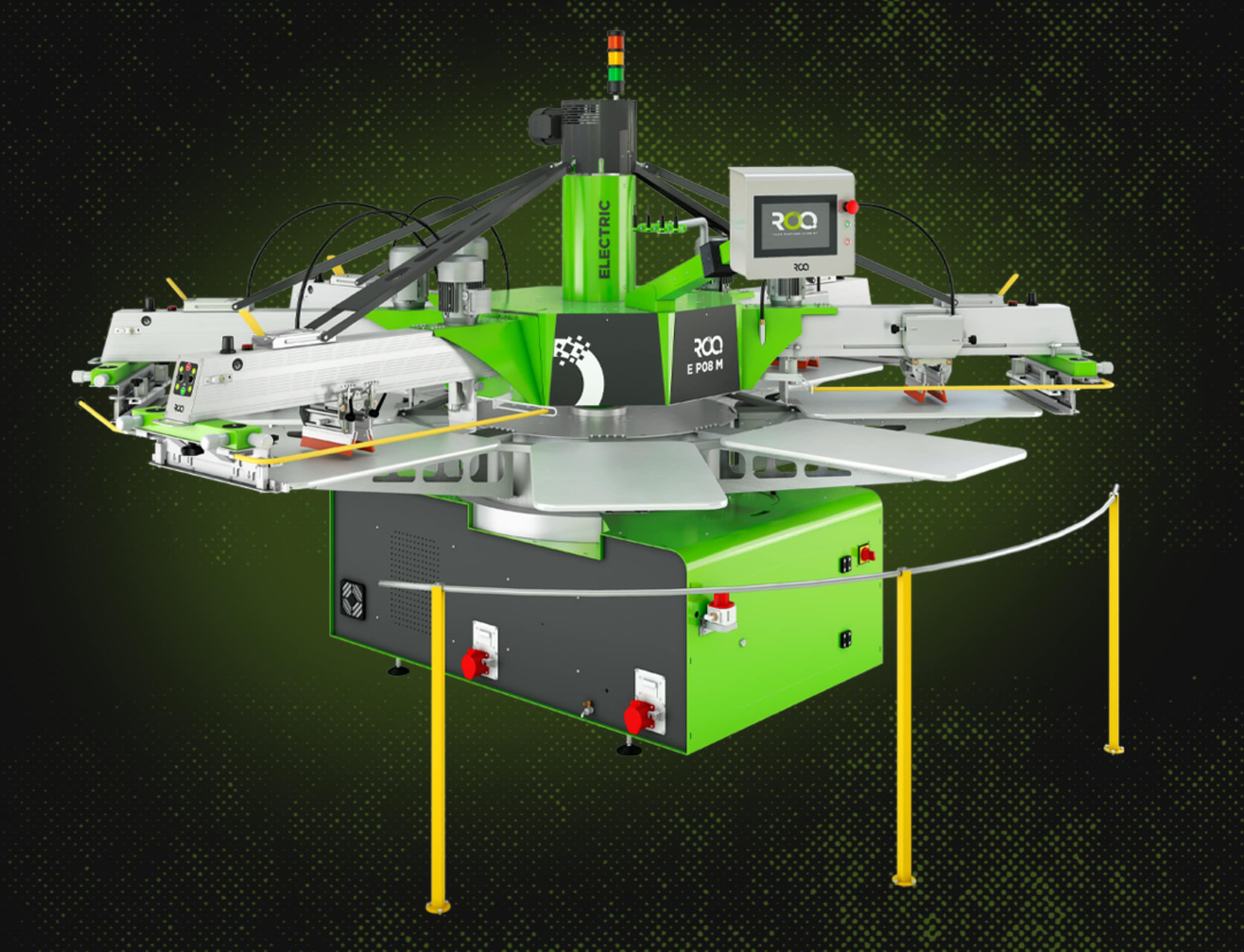

Efficiency is also the name of the game for ROQ. One example is a focus on increasing the integration of analytics and online data from the equipment to provide concise reporting and online communication with enterprise resource planning (ERP) or warehouse management systems, says Ryan Moor, partner at ROQ and founder of Ryonet. Another example is the ROQ E, a new all-electric auto that uses air, but doesn’t need a compressor. “It’s a self-sustained press,” Moor says. “This is good for smaller shops that want the top end of automation but don’t have the space for an air compressor.”

Advertisement

Textile dryer technology has improved to accommodate the burgeoning low-cure ink market. These inks are cured at 270 degrees Fahrenheit, as opposed to the standard 320 F of most plastisol inks.

Textile dryer technology has improved to accommodate the burgeoning low-cure ink market. These inks are cured at 270 degrees Fahrenheit, as opposed to the standard 320 F of most plastisol inks.

THE PERFECT CURE

What’s going on with textile dryer and ink technology? James Ortolani, graphic sales & product development manager for HIX Corp., says he is seeing more split-belt dryer models, which are ideal for higher production. “They can run products at different speeds because of the two belts,” he says. “So if you’ve got a garment that needs to be in the oven a bit longer – say, for curing water-based inks – you can slow one belt down and speed up the other while drying two garments at once.”

These dryers are ideal for curing the hottest trend in screen-printing inks – low-cure inks. These inks cure below 320 degrees Fahrenheit; the usual temperature is 270 F. Lower-temperature curing is useful for polyester fabrics, which constitute most of the huge athletic printing market. Curing polyester at less than 320 F reduces the risk of dye migration and bleeding. However, the main advantages of these inks are energy and cost savings – at least, for those who know how to use them.

The Wilflex Rio low-cure plastisol ink was created to save energy and money by lowering dryer temperatures, which also is ideal for polyester fabrics used in athletic printing.

The Wilflex Rio low-cure plastisol ink was created to save energy and money by lowering dryer temperatures, which also is ideal for polyester fabrics used in athletic printing.

Many screen printers have yet to learn, Sulhadonik says. “I’ve seen just a few shops that already are using 100-percent low-cure inks so they can lower their dryer and flash temperatures. Since most still are using a lot of standard-cure inks, they aren’t doing this, and so they’re not really gaining the benefits of low-cure if they’re still running dryers at the standard temperature of 320 degrees. The whole point is to save energy and money.”

Designed with precision, speed, and ink performance in mind, the RevolvInk Mixer from Ryonet eliminates the need for manual mixing. According to the company, it’s ideal for creating consistent white inks and blending custom colors.

Designed with precision, speed, and ink performance in mind, the RevolvInk Mixer from Ryonet eliminates the need for manual mixing. According to the company, it’s ideal for creating consistent white inks and blending custom colors.

Sustainability is another trend in ink technology. Avient Corp., which manufactures Wilflex, Union, and Rutland inks, has made a permanent commitment to be more environmentally focused, says Ray Smith, field technical service manager for specialty inks and polymer systems.

“No matter what we’re developing, it’s got to be more sustainable than the product we had before,” he explains. “We make sure we’re preserving the natural resources we’re using to produce the ink and are good stewards to the environment. We try to cancel out the footprint that we make things with that will preserve energy throughout our plants, is delivered in a way that is more efficient, and is a cost savings to our customers in the long term. We’re not only designing a good product that does that, but the way we create it reflects upon energy savings.”

Advertisement

The Aquarius line of high-solids, water-based inks from Avient Corp. are designed for sustainability and a soft feel.

The Aquarius line of high-solids, water-based inks from Avient Corp. are designed for sustainability and a soft feel.

Water-based inks continue to gain traction with new printers seeking a soft feel on textiles running on digital hybrid screen printing and direct-to-garment (DTG) machines, Smith says. “Many small- to medium-sized decorators are embracing water-based inks. Plastisol is nice, but for some of the fashion prints it just doesn’t give you the same aesthetic,” he explains. “Printers are learning how to use water-based inks and realize they can print a design on their regular press and create some great looks. They also can be recycled, reused, and remixed to make different colors.”

Specialty inks are also seeing a surge in use as manufacturers scramble to come out with the next best thing. But sometimes what’s old is new. For instance, high-density inks are becoming popular again, Sulhadonik says. “High-density shimmers, glitters and clears all are making a big comeback,” he says. “Creators of fashion retail brands are liking the different looks of specialties, especially for their uniqueness and detailed appearances. Consumers are willing to pay $30 or more for a T-shirt, so there’s more room for profit on these inks, which traditionally are more expensive that regular plastisols.”

That’s just the tip of the iceberg for technology updates for screen printing equipment and inks. Look for more trends at this year’s trade shows, in blogs, and on social media posts from the array of manufacturers committed to bringing efficiency and cost savings to apparel decorators worldwide.

A new all-electric automatic press from ROQ is the ROQ E, which was developed for speed and efficiency for mid- to high-volume textile screen printers.

A new all-electric automatic press from ROQ is the ROQ E, which was developed for speed and efficiency for mid- to high-volume textile screen printers.

Hot Off the Press

With direct-to-garment (DTG) and direct-to-film (DTF) technology continuing to boom in popularity as viable apparel decorating techniques, having a trusted heat press is more important than ever. Today’s manufacturers have answered the call for improved models by offering selections for higher-volume production.

“We’ve seen a resurgence in our air automatic machine, which is a direct result of DTG and DTF decorating,” says James Ortolani, graphic sales & product development manager at HIX Corp. “More people are doing high-production heat transferring. The manual heat press market still is alive and well, but there’s definitely an uptick in air-operated machines. It tells me that people are taking larger orders for DTG and DTF and needing that quick curing turnaround.”

The Sidekick from HIX Corp. is a dual-platen heat press designed for high-production heat transferring.

The Sidekick from HIX Corp. is a dual-platen heat press designed for high-production heat transferring.

HIX and other heat press manufacturers are also looking at opportunities to expedite the transferring process with higher-output machines, Ortolani says. For example, HIX offers a dual-platen machine called the Sidekick that works well for high production with one person running the machine.

“With two platens, you’re able to double production by producing multiple shirts at a time,” Ortolani says. “The air automatic heat presses like this model are ideal for quickly and efficiently curing DTG, DTF, and hybrid designs.”

Advertisement

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns4 weeks ago

Columns4 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Case Studies4 weeks ago

Case Studies4 weeks ago

Textile dryer technology has improved to accommodate the burgeoning low-cure ink market. These inks are cured at 270 degrees Fahrenheit, as opposed to the standard 320 F of most plastisol inks.

Textile dryer technology has improved to accommodate the burgeoning low-cure ink market. These inks are cured at 270 degrees Fahrenheit, as opposed to the standard 320 F of most plastisol inks.  The Wilflex Rio low-cure plastisol ink was created to save energy and money by lowering dryer temperatures, which also is ideal for polyester fabrics used in athletic printing.

The Wilflex Rio low-cure plastisol ink was created to save energy and money by lowering dryer temperatures, which also is ideal for polyester fabrics used in athletic printing.  Designed with precision, speed, and ink performance in mind, the RevolvInk Mixer from Ryonet eliminates the need for manual mixing. According to the company, it’s ideal for creating consistent white inks and blending custom colors.

Designed with precision, speed, and ink performance in mind, the RevolvInk Mixer from Ryonet eliminates the need for manual mixing. According to the company, it’s ideal for creating consistent white inks and blending custom colors.  The Aquarius line of high-solids, water-based inks from Avient Corp. are designed for sustainability and a soft feel.

The Aquarius line of high-solids, water-based inks from Avient Corp. are designed for sustainability and a soft feel.  A new all-electric automatic press from ROQ is the ROQ E, which was developed for speed and efficiency for mid- to high-volume textile screen printers.

A new all-electric automatic press from ROQ is the ROQ E, which was developed for speed and efficiency for mid- to high-volume textile screen printers.  The Sidekick from HIX Corp. is a dual-platen heat press designed for high-production heat transferring.

The Sidekick from HIX Corp. is a dual-platen heat press designed for high-production heat transferring.