ONE RAINY DAY, when I was a kid, I was surfing the channels (this was the ’80s so there weren’t too many channels to choose from), and I stumbled upon these larger-than-life characters battling in this square thing with ropes. I didn’t even know professional wrestling existed because no one around me watched or talked about it. It intrigued me, and from there, I was hooked. I watched religiously until 1999 when I met a friend with a similar passion. We decided to move to Florida to follow our dreams. I’ve been involved in the pro wrestling business for more than 21 years and my body does not thank me.

When I was a pro, I would always see all these guys and girls with their own merchandise. I would ask them where they got it, and they would say they had it made by this company and that company. At the time, I couldn’t afford to pay someone to make shirts, so I kind of put it out of my mind. Until one day, I saw an infomercial for this Yudu machine/kit that had an exposure unit and dryer all in one. It was everything I needed to get started, and it wasn’t terribly expensive. The setup was really primitive and wasn’t how a real screen printer operated as far as screens and equipment, but it was good for a hobbyist. I was given the machine as a birthday gift and off I went. It was a huge learning curve, but as I went on, I was able to incorporate more traditional screen methods to the Yudu, like using liquid emulsion and not capillary films. Soon, I was able to make decent looking shirts.

Screen printing my own shirts was really just for me – I wanted my own identity and to make some money on the side – but the better I got and the more requests I received, I decided to branch out and start making shirts for other wrestlers. I even did shirts for a local bagel shop. The apparel I print is my pro wrestling brand, Turnbuckles and Tackles Pro Wrestling Apparel. A turnbuckle is a part on the ring that holds the rope to the corner post and allows you tighten the ropes, and a tackle is a move within a match.

Printing merch for others ended up being pretty easy. I have many wrestling connections on social media who see my merchandise that I print for myself. They reach out to get something made for their brand. I know how little guys and gals get paid on the independent wrestling scene and they are busting their butts performing in front of very little crowds, so I try to be fair and give them a good deal when printing their merch.

I run my shop, Burning Hammer Screen Printing, from my basement. It has its positive and negatives. I do enjoy printing at home; all I have to do is walk down to my basement, turn on my equipment, and get started. I did have to upgrade my electrical box, which costs money, but that’s about it. I’m also limited on space so right now it’s pretty tight. I’ve found that if I use certain chemicals, like screen opener, the smell can get up into the house, so I tend to go outside if I have to change colors. All in all, I enjoy being in my basement.

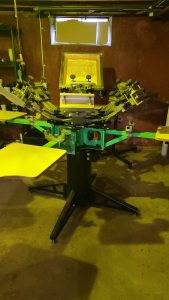

I’ve gone through a few upgrades during my screen printing journey, as most outgrow what they start out with. I’ve been loyal to Ryonet and their equipment as they’ve always been good to me and they do help out the small guy in this business. I started out with a one-color, one-station blue press from Ryonet. It was ok at first, but those are really entry level, so I upgraded to a four-color, one-station press, which I used for a couple years. Most recently, I upgraded again to a Riley Hopkins six-color, four-station press from Ryonet. This was a used model, but it works great. I also upgraded from a very basic exposure unit to a Workhorse vacuum exposure unit.

Advertisement

Whether it’s for myself, other wrestlers, or a local eatery down the street, I love screen printing. Yes, it’s hard work and it’s frustrating when equipment or chemicals don’t go your way, but it’s worth it when I see the merchandise I print out and about all over social media.

PHOTO GALLERY (5 IMAGES)

Case Studies2 months ago

Case Studies2 months ago

Art, Ad, or Alchemy2 months ago

Art, Ad, or Alchemy2 months ago

Andy MacDougall2 months ago

Andy MacDougall2 months ago

Columns4 weeks ago

Columns4 weeks ago

Editor's Note3 weeks ago

Editor's Note3 weeks ago

Marshall Atkinson3 weeks ago

Marshall Atkinson3 weeks ago

Thomas Trimingham2 months ago

Thomas Trimingham2 months ago

Case Studies4 weeks ago

Case Studies4 weeks ago